New Large Format IDEX Printer Project

-

-

@sebkritikel Thank you very much for sharing, very nice job/build.

I am currently also constructing/building a IDEX printer.Would it be possible that you share the configuration files?

Regards Mark,

-

@mdejong said in New Large Format IDEX Printer Project:

@sebkritikel Thank you very much for sharing, very nice job/build.

I am currently also constructing/building a IDEX printer.Would it be possible that you share the configuration files?

Regards Mark,

Config files

https://drive.google.com/file/d/1YFRLG1p-1BWzesjVF5xkvDGQXmHolgCN/view?usp=sharingA few macros.

https://drive.google.com/file/d/1JYeDPMh5vsuDdju80Gcau3OX2jCOVeex/view?usp=sharingHopefully they help!

-

@sebkritikel Thank you very much it will help me alot.

-

Thanks for sharing all the details of your printer. I saw the screenshot of Cura. It's that in your opinion the best slicer for your IDEX printer? Did you try other slicers as well?

Best regards,

Jeroen

-

@gjwater My apologies for the delay in getting back to you!

I can't say for sure that it is the best, but I do enjoy using it and have a fairly robust IDEX process that works nicely with Cura. In all, I have about 3.5 years of IDEX experience with it (starting the the BCN3D fork of Cura that natively supports their Marlin-flavor of mirror+duplication modes).

With any slicer - it is important to identify what messages or scripts are placed into slicer-generated pre/post/start/end gcode sections vs. what is used in Duet/RRF tool change scripts. Over time I've moved as much as I could out of the slicer and into my tfree, tpost, and custom tool changes macros on the Duet.

-

undefined sebkritikel referenced this topic

undefined sebkritikel referenced this topic

-

Sorry for writing in old theme, but I think it could be useful to be found in the same place.

First @sebkritikel very impressive work. I did build in the past a few machines, including IDEX and actively heated ones, but not in the same setup.

I am planning to build a new one and might be using your design as a foundation.

One thing I do not see in CAD and I think is not mentioned anywhere.

How do you align in the Z axis both IDEX heads? In my experience, this is the key for printing in copy and mirror mode -

@martin7404 No worries! And thanks for the comment.

You're right that for mirror and copy modes, you want the nozzles to be closely aligned in the Z axis. Unfortunately I did not design in any provisions to mechanically level the two nozzles, as my BMG extruders essentially directly mount to my X & U rail blocks. This hasn't been too much of an issue for me, as I typically print in 'normal' mode (build tool and support tool, dual color, etc), but I could deal with any Z variance by printing in mirror/copy modes with a raft.

If I were to do IDEX again, I would definitely make my tool heads a two-part system - I would have the motion carriage, and then the tool plate. The tool plate (extruder, hotend, fans, etc) would mount onto the motion carriage, and could be mechanically adjusted at least in the Z axis. I'd then use something like the door knob "KnobProbe " to check Z offsets, and also improve how I've used TAMV to align the X/Y and Y axes (I've also seen this product, but haven't given it a try https://www.emberprototypes.com/products/cxc).

Some other recommendations I have

- Design a fully fleshed tool head before committing to and detailing the rest of the printer build. I essentially did the opposite - started from the outside, ending my design+build with the tool heads (I thought they would be easy). Quite the opposite

- Make sure your tool heads can be easily worked on. I would not put significant effort into making them compact, with lots of fiddly screws.

- Design mounts for input-shaping accelerometers close to/on the tool extruder. (Can be accomplished with the Duet 3 tool boards). You want the accelermoter as close to the nozzle as possible, and rigidly mounted near it to truly characterize the motion+vibrations.

- Have a thermistor/thermocouple mounted on each tool to measure the ambient/chamber air - maybe near the hotend cooling fan inlet. Helps you keep an eye on what the chamber temperature of the build volume is.

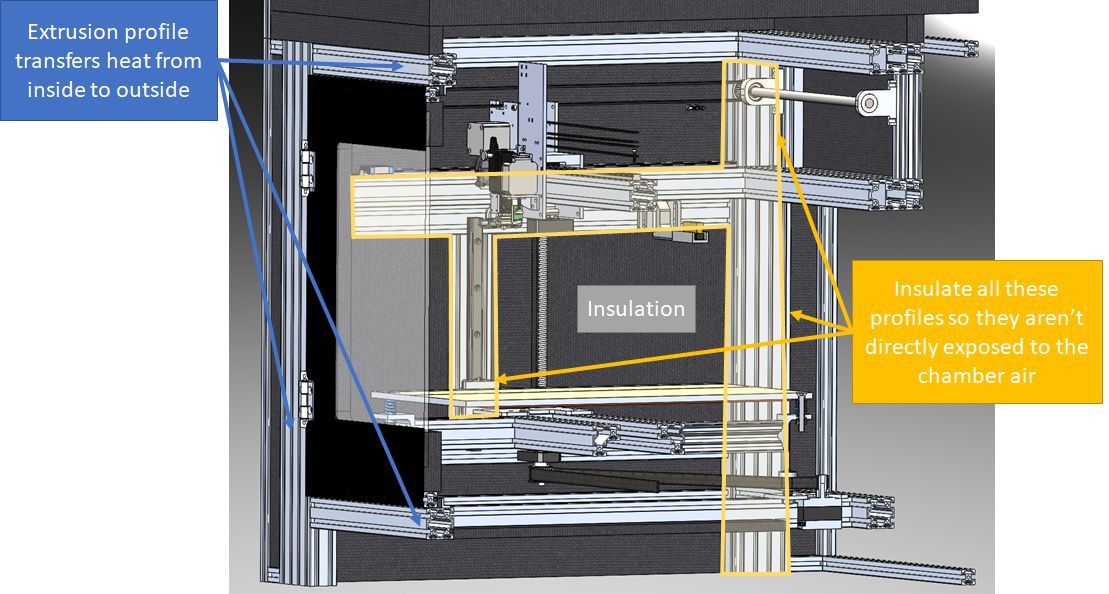

- Try to insulate as much of the frame as possible from the chamber air.

- Really put effort into the 'parked' positions for each tool head. You want space to purge material, perform nozzle wiping activities, etc.

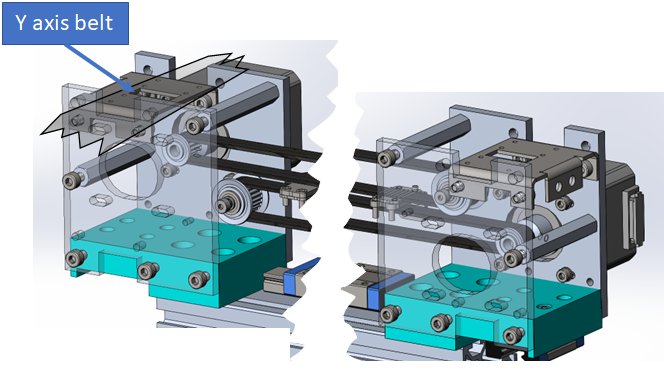

- Ensure all belts, pulleys, shafts are in double shear. You don't want to put massive radial loads on stepper motors while getting the belts to the correct tension (in fact, it likely cannot be done). My X and U motors are in single shear, I would absolutely either do like I did on the Y axes and isolate the motor from the Y-axes motion belts, or use a shaft coupler, with the secondary shaft+pulley in double shear.

- Definitely research magnetic/removable build sheets. Initially I went with a 5mil PEI sheet, which worked pretty well for all the materials I used, but that thickness is delicate. I recently switched to a 40mil PEI sheet which is significantly more durable. Heck, I'd be curious if I could go thicker (of course, 40mil was expensive, like $160 USD).

- Put some thought into what cables you use (motion rated, bend radius) you use for each toolhead, and how you manage their motion (energy chains, etc). Make sure that for each printing type (normal, copy, mirror) you don't run into any physical cable routing issues (cables getting caught on framing, or pushing into each other, bending into belt paths, etc).

- Look into an equivalent of https://sendcutsend.com/ for your area, and design to their capabilities. Their prices, lead times, material options are amazing, and can make cost-effective alternatives to using pure aluminum extrusion (and the associated t-slot nuts, etc).

I'm reading this forum daily, feel free to reach out if you have any other questions or ideas!

-

@sebkritikel Happy new year. Thank you very much for the guidelines. For tool heads I think I will go with Hemera, I have one running in a chamber for more than a year and a half. Another option is biqu h2 500, which is designed for heat chambers, this has the great advantage that the heartbreak can be adjusted in height and one great disadvantage of having not hardened drive gears

-

A few changes from the previous status

- April 2022 - reworked the X-U axis motor mount / bearing block mounts, as well as tool plates using cut and bent parts from SendCutSend

- April 2022 - swapped out X / Y / U bearing blocks from no preload to preload

- October 2022 - Present - experimenting with alternative extruder designs (small Nema8 motors, DC motors)

- March 2023 - swapped out the Duet 2 + Duex5 with a Duet 3 6HC

Had been wanting to try out the SendCutSend service, and stiffening up my X-U rail assembly was a good excuse to try it out. The vertical members (total quantity 4) are actually the all same plate - installed mirrored depeind on if they are on the high side or low side of the shared axis. Flat plates are aluminum, bent were in stainless. Total order price was a touch under $100 (~$10 a part). Idler pulleys are now fixed properly (using shoulder bolts that actual bear onto the surface). Tapped all the holes once I received the parts.

Previously the X, Y, and U bearing blocks were all clearance blocks (no preload). Was able to change all four out for IKO blocks with preload - this stiffened up the system by a surprising margin, increasing my input shaping target by ~20Hz! (Measurements taken after installing the SendCutSend parts)

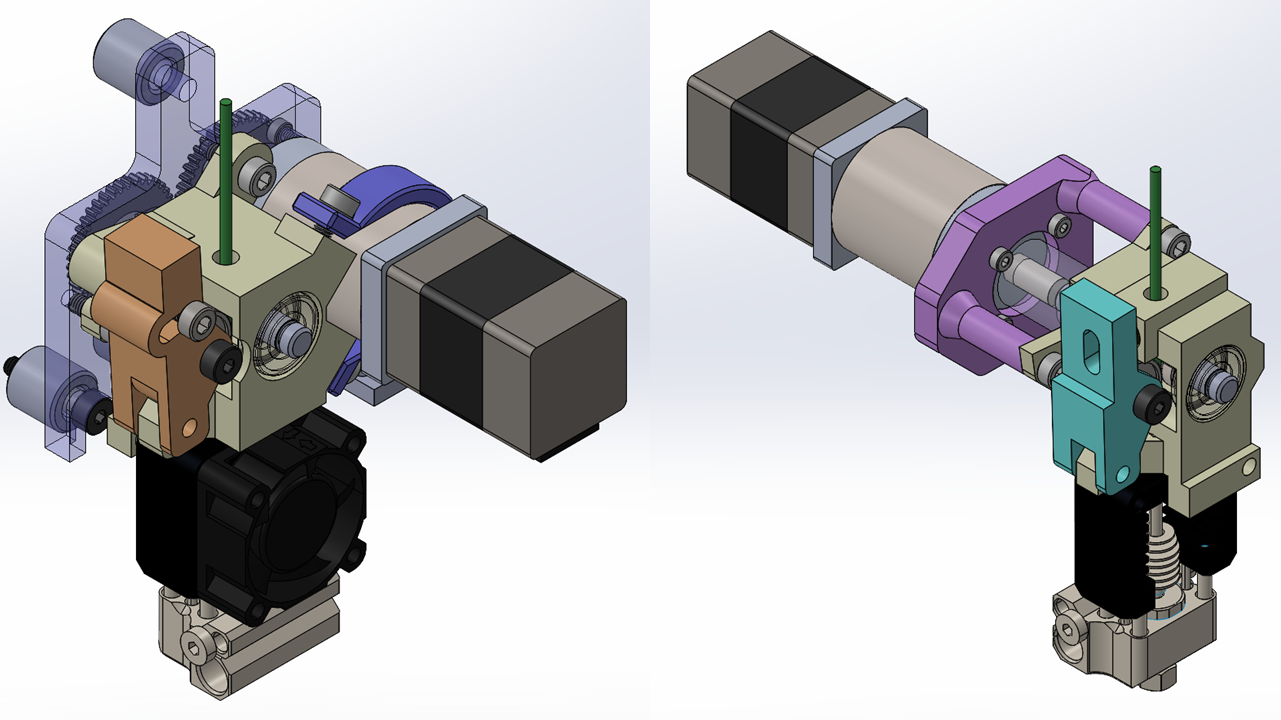

I picked up a really neat Nema8 with an attached 16:1 gearbox off eBay. While researching the motor, all of the extruder requirements seemed to check out - motor and output shaft could rotate at an appropriate speed with sufficient torque - all with a steps/mm value of 2292 (16x microstepping, typicality a standard value). The first crack at installing it into the printer (below left) worked pretty well - had the motor offset from the drive gear (experimentation has been with a single drive extruder, rather than dual extruder gears) using 2x printed spur gears, with the drive gear being a Bondtech BMG gear. Had some print artifacts resulting from surface seams on the printed gears, and eventually one of the printed gears slipped loose (didn't want to overtighten the set screw).

For further testing, I put the motor inline with the drive gear (above right) using a shaft coupler I had on hand. A bit long in this setup, but has been working quite well! Verdict is out on if my hackish extruder designs are any better than a 'commercial' product, but I've been comparing to a BMG setup that doesn't seem to exhibit the extreme VFAs that others have experienced.

The Nema8 experimentation led me to try out the geared DC motor from a Stratasys Dimension machine, which I detailed here some:

https://forum.duet3d.com/topic/31642/duet-2-wifi-and-geckodrive-g320x-on-stepper-channels-10-and-11/11?_=1680448852416While I was able to get it working, and print quality seemed solid, I think the Stratasys machine does some additional tricks to manage the load on the DC motor. I was finding with the Geckodrive (0-20A output) there was a fine line between the motor stalling/faulting on moderate extruder accelerations, and overheating the motor. I would typically see a 35°C thermal rise using the Geckodrive directly with the Duet 2, whereas in the Stratasys machine (all original controller boards) I would only see a 18°C thermal rise.

https://www.youtube.com/watch?v=vvajxcZIf6MFinally, this past week I upgraded to a 1.02 rev of the Duet 3 6HC. Currently still running with 24V. Overall the swap went over smoothly.

- I like how simple the pin names are in comparison to the Duet 2. Not that it was confusing, but something like io0.in is easy to understand and type.

- Motors and motion sound a touch different - almost like they resonate at a slightly higher frequency, with a little more consistency, but not really any louder?

- Only hiccup I had was wiring and sending signal to my heat bed SSR. I am using Out 0 to drive the SSR, but did not provide an input to Out 0 power in.

- VH contacts crimp fairly easily.