Want input on frame design

-

A couple more random thoughts. Aluminium is preferable to plastic parts of you have access to the necessary machining capabilities. If you do need to print any parts, avoid PLA like the plague, especially if you live somewhere that has warm summers or if you want to use a heated enclosure. Use a more heat tolerant filament. In any case, I'd highly recommend using aluminium for all motor mounts. It's a good conductor of both heat and electricity so the entire frame will act as giant heat sink and the motors will run so much cooler. Also, it'll act as a ground plane for any static that might build up. On that topic, earth the frame - preferably in several places. Tie the frame to PSU gnd and make sure that the print head is also tied to gnd.

I'd also highly recommend that anything that carries idler pulleys or wheels is supported at both ends. Otherwise they'll twist under tension.

-

@deckingman yeah, the only access I have is if I use a CNC mail order service.

-

I designed my bulldog printer to not use any custom machined parts (and no structural 3D printed parts either). All custom metal was designed to be lasercut. I primarily used 1/8" (3mm) plate, with a few thicker parts. I've had very good service from a place in the US (Reno Nevada) called sendcutsend.com. I'm not affiliated, just a happy customer. Good prices, fast service, and instant quotes on uploaded DXF files. I've had some orders shipped in less than 3 days.

-

@mikeabuilder Sendcutsend is getting awesomer by the day. Documentation has gotten even better, great value with the insert/stud capabilities, finishing turns out great. Both personal project and work related parts have all turned out fantastic.

-

@sebkritikel I've played with their quoting tool, IIRC, it was prohibitively expensive. Worth looking again though.

-

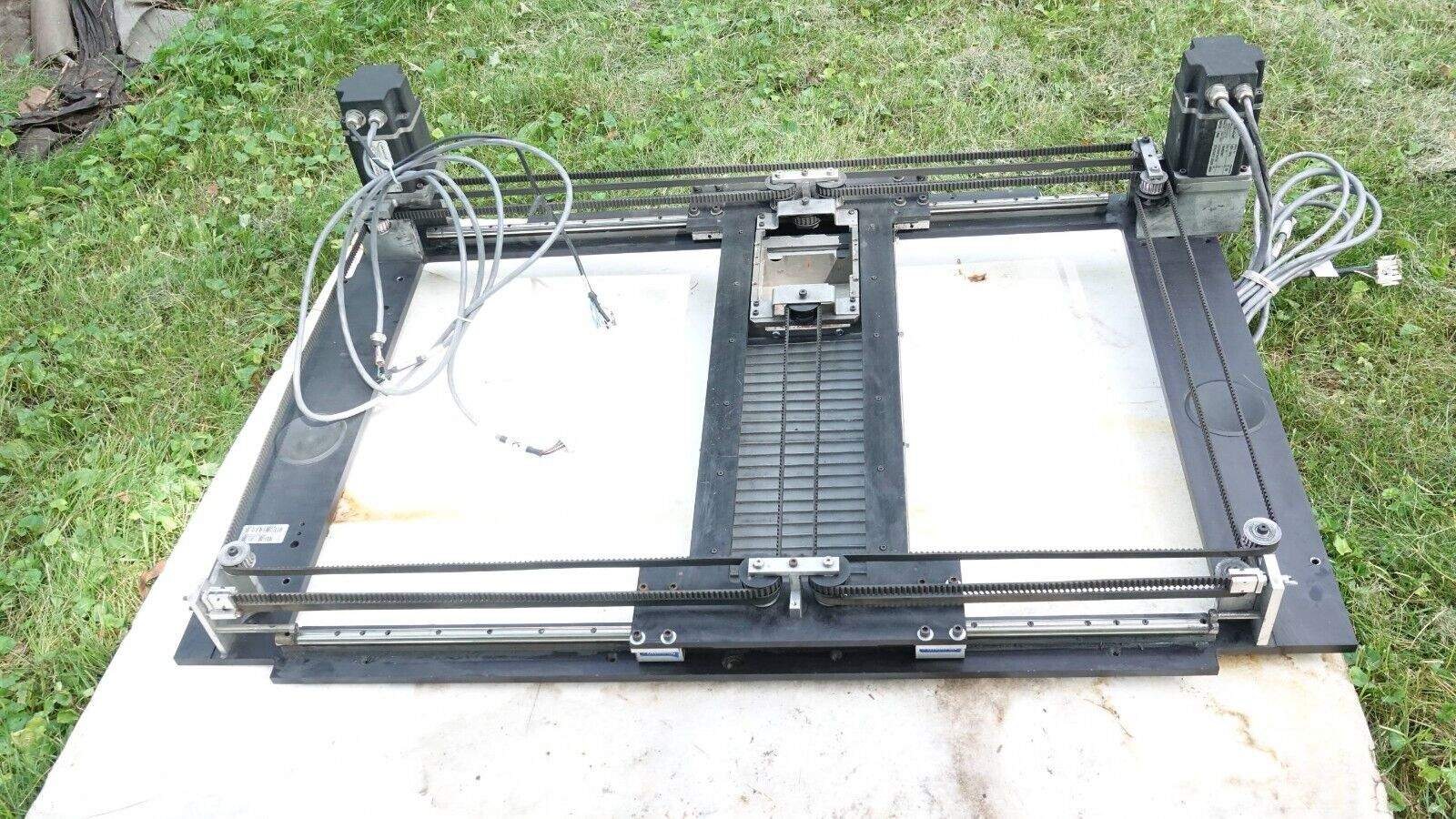

Playing around. I've done double gantry rails before, was super rigid. Thoughts?

It's a 6x6.

-

@gnydick Honestly I think the combination of the aluminum frame assembly, double gantry rails for the X and Y axes, and the associated belt pathing is unnecessarily complicated and would be really tough to assemble (and maintain).

I think sticking to a single linear rail profile of a beefier profile for the Y-axis is a better option than the double stack you have shown. I'm thinking something greater than a rail width of 15mm (vs the 9mm or even 12mm thats common for DIY printer builds).

For the X axis segment, I also thing the double stacked system is overly complicated. You could do a similar setup as my below image where two rails are arrayed horizontally rather than vertically, but if your goal is tool changing, this might not be feasible.

I think the aluminum profile can be a really good option for vertical members of the build, but I think for a CoreXY (or really any sort of motion system where the bed does NOT move horizontally) a large, flat surface with limited vertical beams gives you the best chance to have a quality mechanical layout.

-

@sebkritikel I know what you mean. If I was to go this route, each stacks would be joined in a block. Otherwise there'd be a lot of potential for problems.

-

@gnydick I use double X rails but side by side, just so that I can sling my heavy, multi input hot ends between the rails. But the downside is that I lose potential Y travel. I'm working on a design which will have just a single input hot end - probably a Bondtech LGX Ace with Slice Engineering Mosquito but that will just use a single rail - probably 2040 on it's side so the 20 will be in the Y direction and the 40 being the depth. That should give me the Y travel I'd like whilst being stiff enough.

-

I'm also not a big fan of doubling up the rails. If you are contemplating doing it, you need to think about how you'll keep both rails perfectly aligned. If they are slightly off, they can easily jam instead of rolling smoothly. You'll certainly get experience with this effect when you work to align just two Y-rails. If you do pursue this, mounting both on the same piece of material is a good solution. That way, the pair of rails can be aligned one time and should stay that way.

I also recommend thinking hard about what forces those additional rails are counteracting. Usually, this means some mass that's located away from the sliding block, or belts that are connected far from the sliding block. These can put torques on the block during a fast stop or start and those torques can lead to undesired movement of the nozzle. Does the added rail counteract the torque well? Why is there so much torque in the first place? Why is this helping?

My personal design direction in this case was to design the belt fastenings to be as close to the sliding blocks as possible and to try to keep the mass of the print head also as close to the sliding block as possible. If the moment arm is short the torque will be lower.

-

@mikeabuilder yep. pretty much the toolhead is not going to be centered because it's a tool changer.

-

What do people think of the Annex K3 cross rail setup? Doesn't seem like a good candidate for the tool changer, so just curious.

-

@gnydick Having recently embarked upon a new printer design myself, it occurs to me that there area few things I've learned which might help.

Firstly, decide what print area you want to end up with. Then you'll likely need 50mm either side for frame members and Y axis gantry plates. Then hot end, fans etc could be about 80mm wide so you'll need another 40mm or so either side of that making about 90mm either side or say 200 mm in total to be safe. So add 200mm to your print area dimensions and that should give you outer dimensions of the frame (or thereabouts).

Secondly, model the belts. Just simple cubes will do. Say 1.4mm x 6mm tall (or whatever belt width you choose) x whatever length each axis is.

Thirdly, model the pulleys and idlers and their positions relative to the belts. Once you have the belts run, then for toothed pulleys, you'll find that about 0.8mm of the 1.4mm thickness engages with the teeth of the pulley and about 0.6mm is proud of the pulleys (measure you belts and pulleys to be sure). Do the same for toothed idlers but if you use plain idlers, then there will be no tooth engagement to allow for.

Having (accurately) determined the positions of the pulleys and idlers, then you can go ahead and design the gantries and mounts such that the holes will all line up, and when you assemble it, the belts will be parallel when they need to be.

Then as the design progresses, model all the bolts, screws and fixings. Nothing too detailed - just simple cylinders will suffice but make sure you allow for the head diameter. You need to determine where they will be fitted so that fixing holes all line up and that the heads won't foul on anything, but more importantly you need to be sure that you can get a tool in to tighten them. Also, if you use slide in Tee nuts, make sure these are denoted somewhere. I know from experience that it's very frustrating to fit a frame member then later discover that you forgot to put in enough Tee nuts to mount something or other. So having these marked on the design will help with assembly. Admittedly, one can use drop in Tee nuts but personally I hate the bloody things as they never quite rotate in the slot the way you want them to.

Hope those pointer might be of some help.....

-

@deckingman that's all good advice. I'm being very diligent about keeping my Fusion 360 design parametrically clean.

I've put all of those measurements in as used parameters and have a frame that resizes accordingly in every direction.

The secret is to use assemblies.

-

Great to see more Fusion360 users. It's a great tool. And great advice from @deckingman on how to design for the belts, and including all fasteners. I even include washers in my designs.

My general F360 advice (if you are not already doing these things).

-

Make sure all your sketches are fully constrained.

-

Use moving joints for moving parts. It's great for looking for things that will crash into each other.

-

Assemble your parts in the timeline in the same order as you'll assemble in real life. It's help expose places where things are hard to assemble.

-

This one is controversial, but I design most of my parts in separate files and link them into the main assembly. The good part is a simpler main assembly. The bad part is lack of ability to project features from existing parts. For parts that benefit from a lot of projections, I'll often design them in the main assembly file, then export to a stand-alone file when the design seems stable.

-

For flat parts that will get laser cut from sheet stock based on DXF files, I create a new sketch as the last part of the design that captures the whole part. This way, I get a DXF file where I don;t need to delete construction lines.

-