Number of teeth engaged

-

@fma said in Number of teeth engaged:

Is it better than Gates idlers?

I'm not sure if it's better than gates, but using flanged bearings does allow for more choices of hub and outer pulley diameter.

-

@mikeabuilder Good point!

-

This post is deleted! -

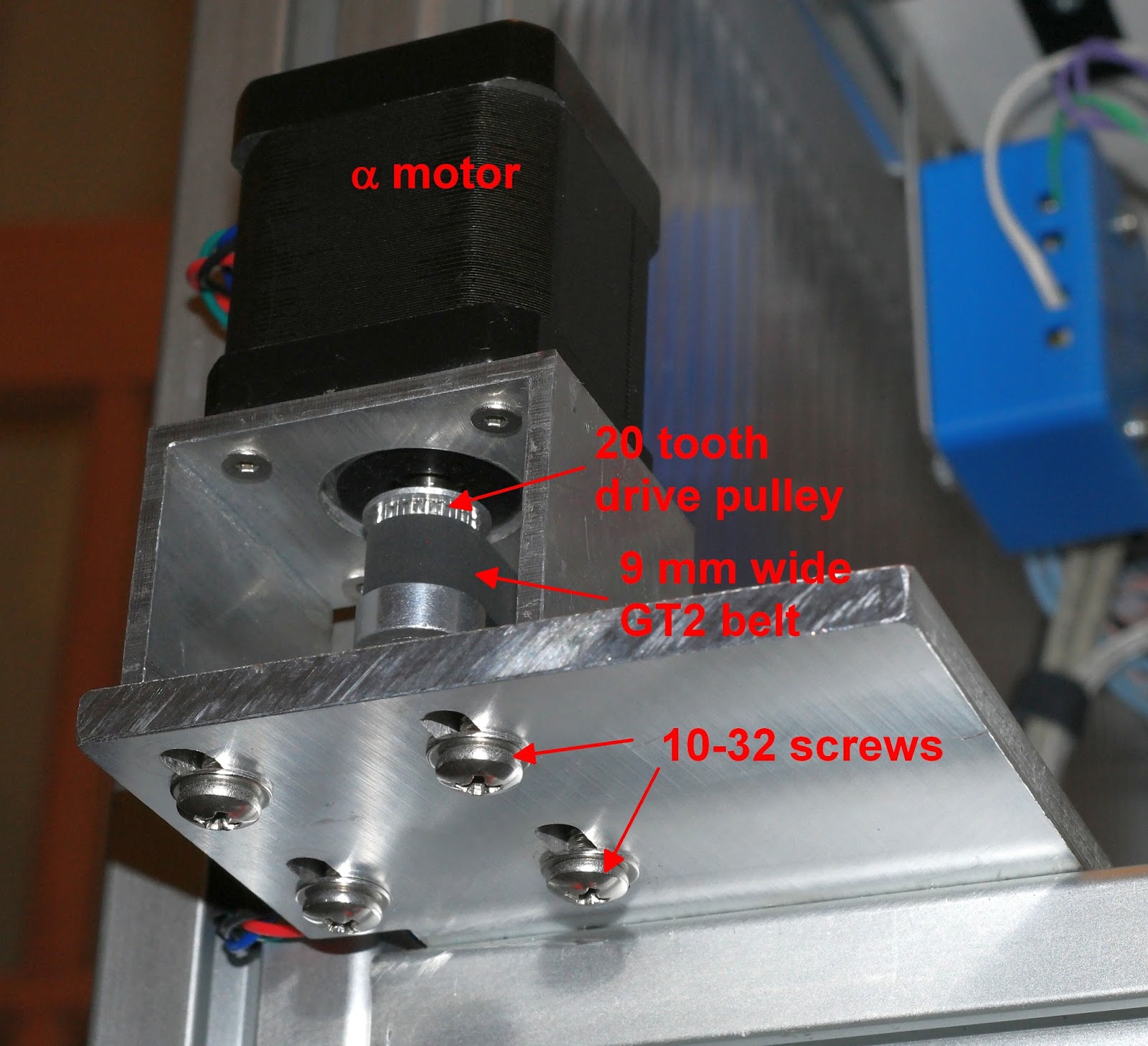

@arnold_r_clark I use stacked belts, too, and avoid adding additional pulleys to adjust belt tension by mounting the motor mounts on slots that allow them to slide.

You could also adjust belt tension at the extruder carriage without adding any extra pulleys.

-

This post is deleted! -

I designed a mechanism that connects my top and bottom belts together into a continuous belt so that the tension in both belts is equalized. And then I use the "sounds and feels" good enough method to set the tension.

-

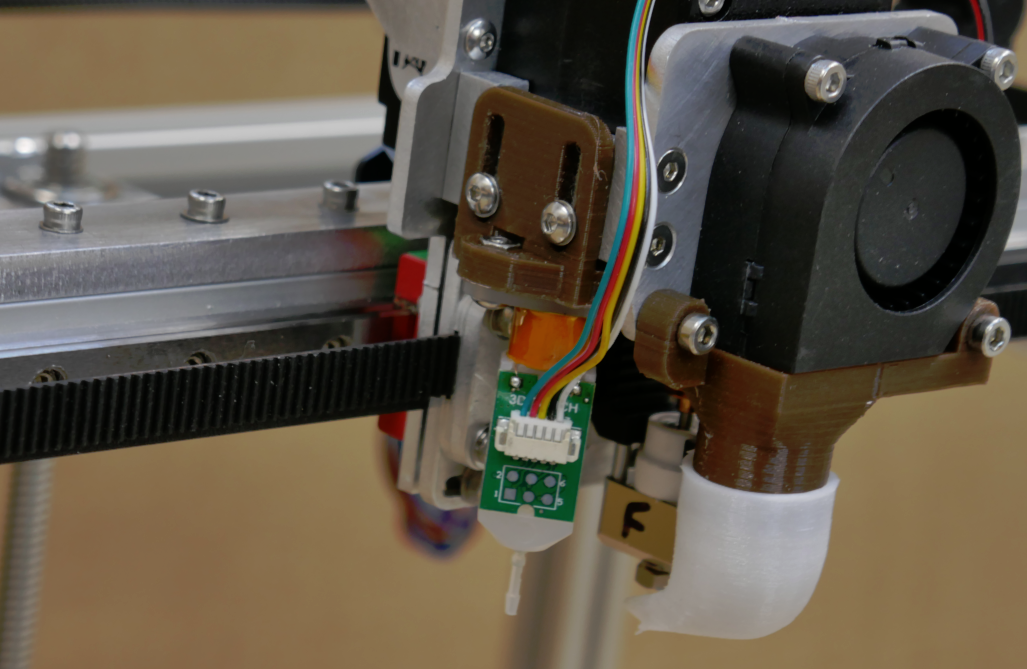

@mikeabuilder Amazing, I also have a continuous belt, which turns around a free pulley on the carriage, which I then secure with a screw, to get 2 independant belts!

-

@fma - I like the pulley concept but it does require the belts to have zero z-offset, which explains your use of the PTFE belt separator at the crossover point. I separated my belts by 3mm in Z and that leaves me a 1MM gap between the belts at the crossover. Knowing that your PTFE solution works may bring me to a zero Z offset on a future iteration of my design.

-

@mikeabuilder If you stack the belts (12mm vertical) you don't need for them to be in contact at all, and they can share axles...

-

@mrehorstdmd - You're correct. It's all a question of design tradeoffs. For my design, I worried about the way both Z and X offsets in the belts "might" cause unacceptable torques on the print carriage, so I opted for a design that kept the offsets really small at the carriage.

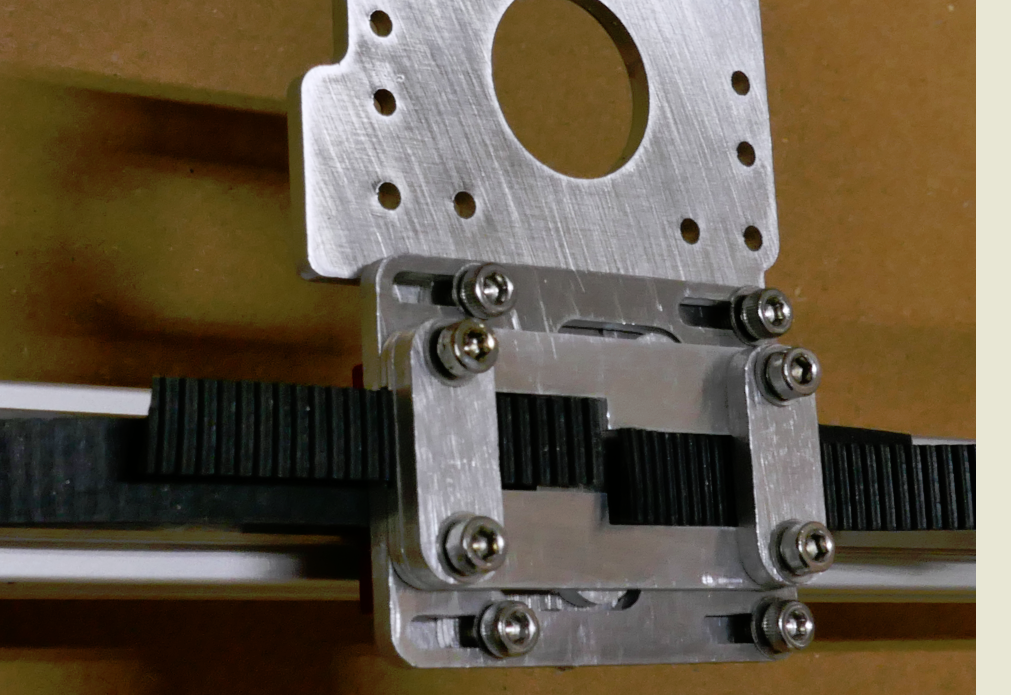

Here's the completed assembly

And here the clamping mechanism behind it where you can see both belts better. The belt centers are offset 3mm in Z and 4mm in Y.

It's great that there are so many variables to play with. Makes lots of opportunities to engineer for fun.

-

A word about idlers (I didn’t quite see if the designs have this): Smooth idler on the tooth side of the belt will cause small but noticeable irregularities on the movement (on one of my prototypes, about 0.02mm).

-

@juku That depends on the diameter of the pulley. I specifically chose F608 bearings for pulleys in my printer because they meet the Gates recommended minimum of 9 teeth in contact with a smooth pulley surface. I get no print artifacts from the smooth pulleys.