Part cooling fan not strong enough

-

Hi,

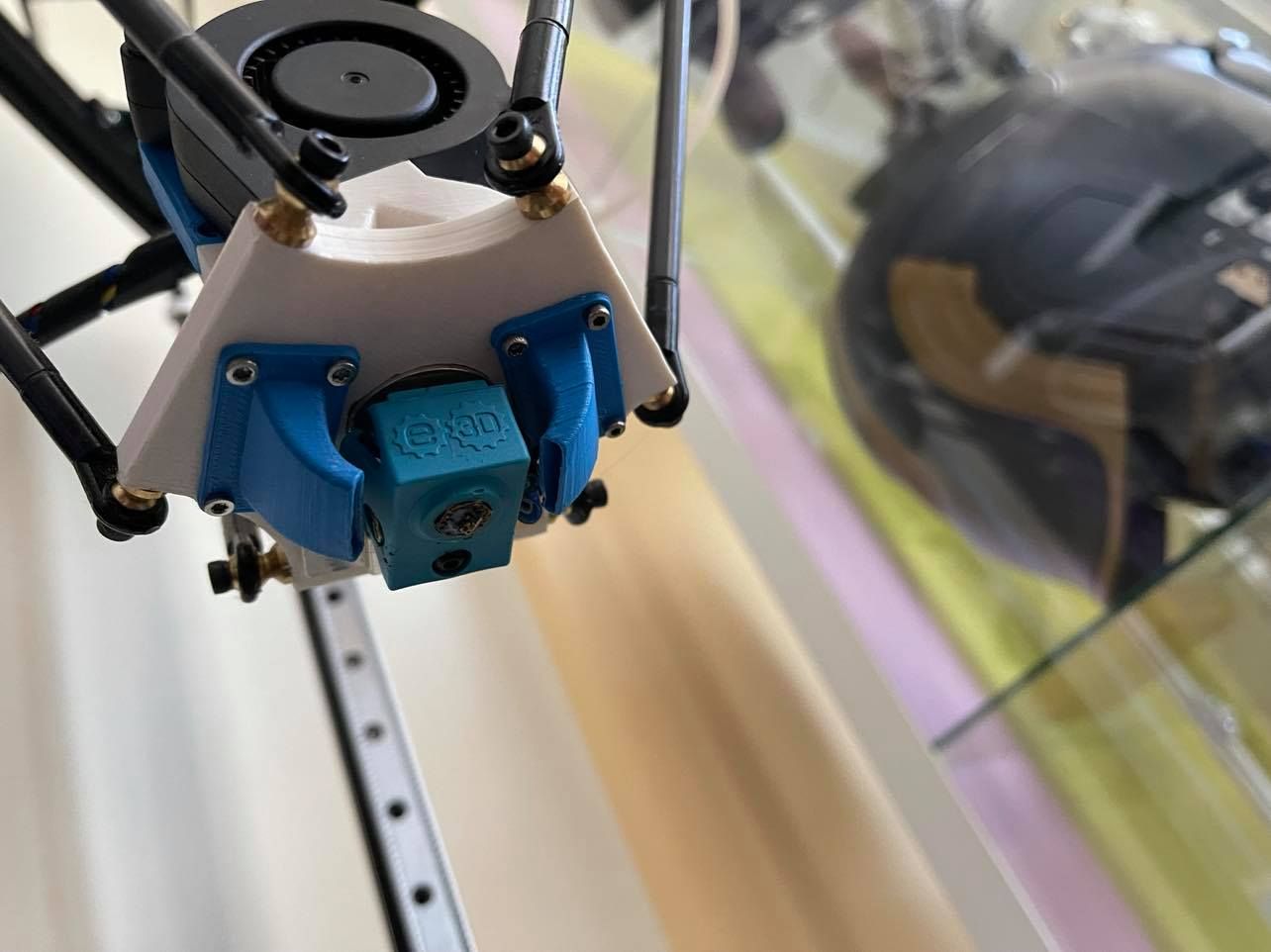

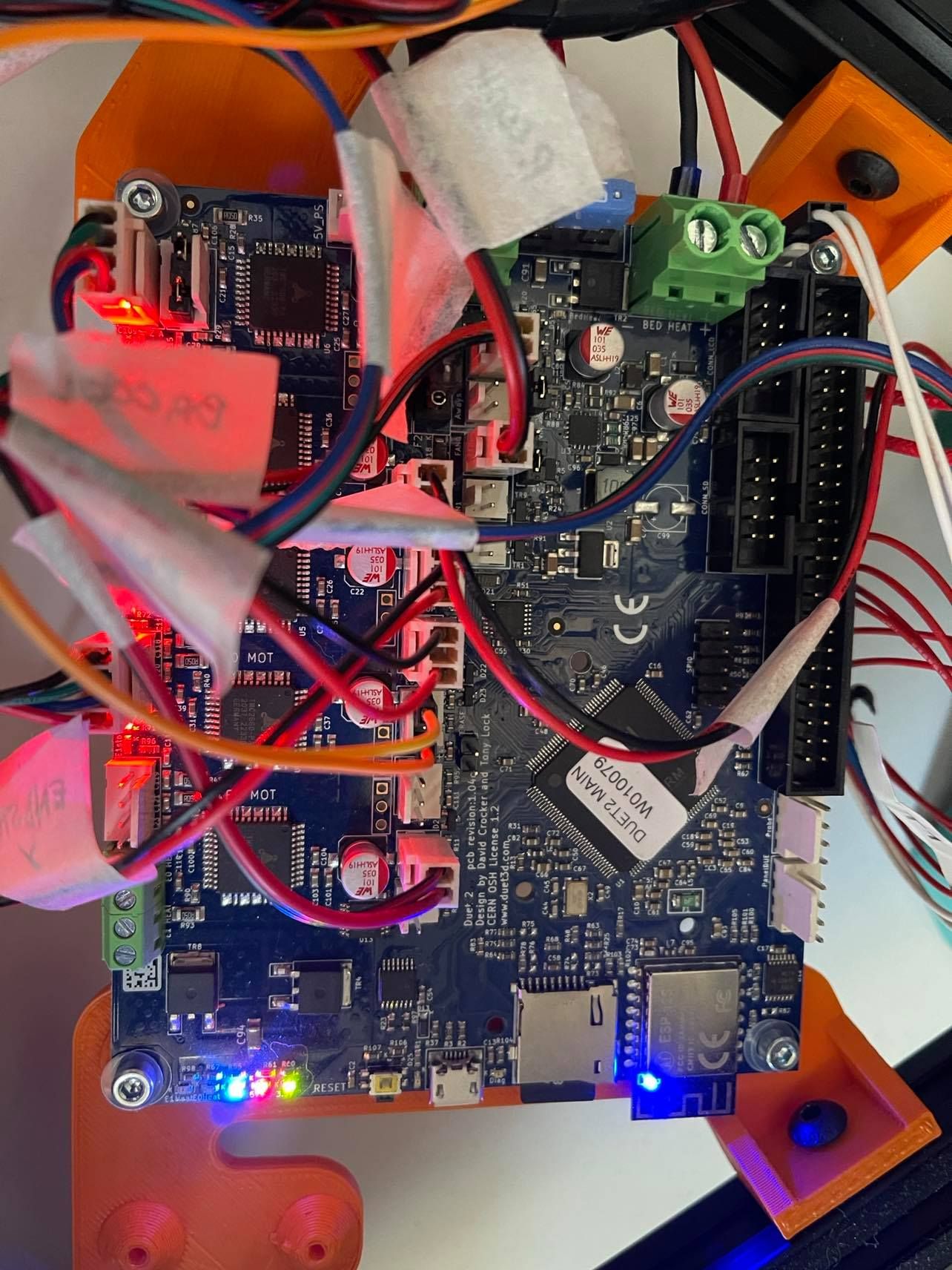

So I'm a beginner to intermediate in 3d printing. I can understand configs and the basics of how things work and I managed to set up an older Anycubic Kossel with a Duet3d Wifi. Everything works but I'm having problems with part cooling. The Fan is a turbine 12v 50x50 and while it works correctly I feel like it's not giving the proper cooling. I keep testing with the benchy print and the front of the body, where the overhang should be tested is not going well.

I'm printing PLA at 190 with 80mm/s speed (0.3 and 0.2 layer height). Played a lot with temps, speeds, flow, and nothing changed and that's why I reached this conclusion.

So is there any way of increasing fan power beyond the default max or something like that? Or any other solution. I don't think a different cooling duct would work better. And I tried the fan on a different Kossel with the same effector but with the stock board and it definitely sends in more air.

Here is my config file:

config.gand here are some photos with one benchy and my board wiring and part cooling ducts.

Cheers

-

; Fans

M950 F0 C"fan0" Q50000 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned offYour fan frequency is very high. Set it to 500, not 50000

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

This is not the correct thermistor setting for an E3D thermistor (assuming you fitted one of theirs when fitting their hotend)

-

@andreic I think your ducts produces to much back pressure. You should test the fan in "free air" for comparison...

-

Thanks for looking and answering. Yeah, I did a test with that frequency just to see what happens. it's 500 now and it was before too.

About the thermistor thou, I did not notice that. I followed some instructions on what to select and I did not check on the thermistor for E3D. You are right it is a full E3D kit and it has the E3D Thermistor.

Can you help me out with some info on what should be there instead? I didn't have problems with it but I'd rather have the correct settings.

Thanks again

-

@cosmowave

Yep tried it. I have an identical one on another Kossel with stock board and it works great and I have been using it for a year.cheers

-

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; -

just tried it and it seems to be messing up my bed thermistor or something

Error: Temperature reading fault on heater 0: unknown sensor -

@andreic post your whole config and the output of M115

-

M115

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.2.2 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2021-02-11; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Mar 23 2021 21:22:33 GMT+0200 (Eastern European Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Kossel" ; set printer name M665 R133.755 L285 B115 H271.591 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X-0.84 Y0.04 Z0.79 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E422.10 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop ; Z-Probe M558 P5 C"e0stop" H5 F100 T6000 ; Set Z probe type to switch and the dive height + speeds G31 P1000 X0 Y0 Z13.8 ; Set Z probe trigger value, offset and trigger height M557 R105 S20 ; Define mesh grid ; Heaters M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H1 R1.892 C235.1 D6.18 S1.00 V12.5 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q50000 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T50 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M501 ; Custom settings are not defined -

@andreic you've changed the temperature sensor for your bed rather than the hotend.

That's why your bed isn't working correctly.M308 S0 p"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H1 R1.892 C235.1 D6.18 S1.00 V12.5 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 -

yeh...you're right. hurry makes stupid.

Works now. gonna do some tests with this tomorrow.Thanks and i'll get back with the results.

-

@andreic Perhaps somebody replaced the original fan with a quieter one but didn't check the CFM rating and it's too low.

-

@donstauffer

Nope. Tested it on the other system and there is a clear difference.@jay_s_uk

Still the same problem after a PID tune too.