Chamber heater plan

-

@oryhara I use a bare thermistor to check chamber temperature. Those canned things are good if you need to mount them in a heater block, but in air they are going to slow down the readings because all that mass takes time to heat up. The little glass bead type thermistors have very low mass so they follow temperature changes quickly.

This is the chamber heater config I use:

M307 H2 A11 C99000 D2000 B1I mounted the chamber thermistor about half way up the Z axis:

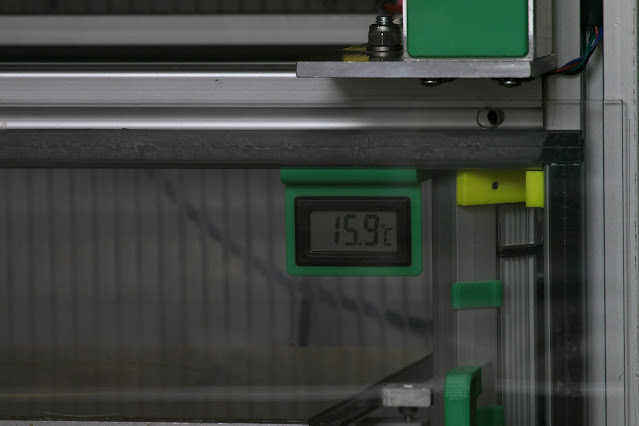

I installed a little $5 LCD thermometer in my printer, near the xy stage to monitor chamber/ambient temperature at a glance, even when the printer is off.

-

This post is deleted! -

It works. Took about 23 minutes to reach 50 degrees.

I want to thank everyone here for their help.In case anybody wants to repeat my success, here is what I did:

this heater element:

https://www.mcmaster.com/3575K411/

with this fan:

https://www.mcmaster.com/1976K95/

this SSR:

https://www.amazon.com/gp/product/B07FVR37QN/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

this thermistor:

https://www.amazon.com/gp/product/B07V6YBFSY/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

and this TCO:

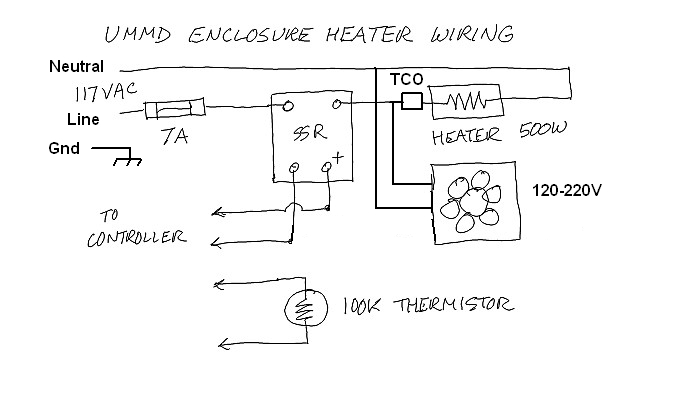

https://www.amazon.com/gp/product/B07JM2DB67/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1Wired them up per this diagram

@mrehorstdmd said in Chamber heater plan:

Wiring:

-

@oryhara Photo of the assembly?

-

@mrehorstdmd said in Chamber heater plan:

@oryhara Photo of the assembly?

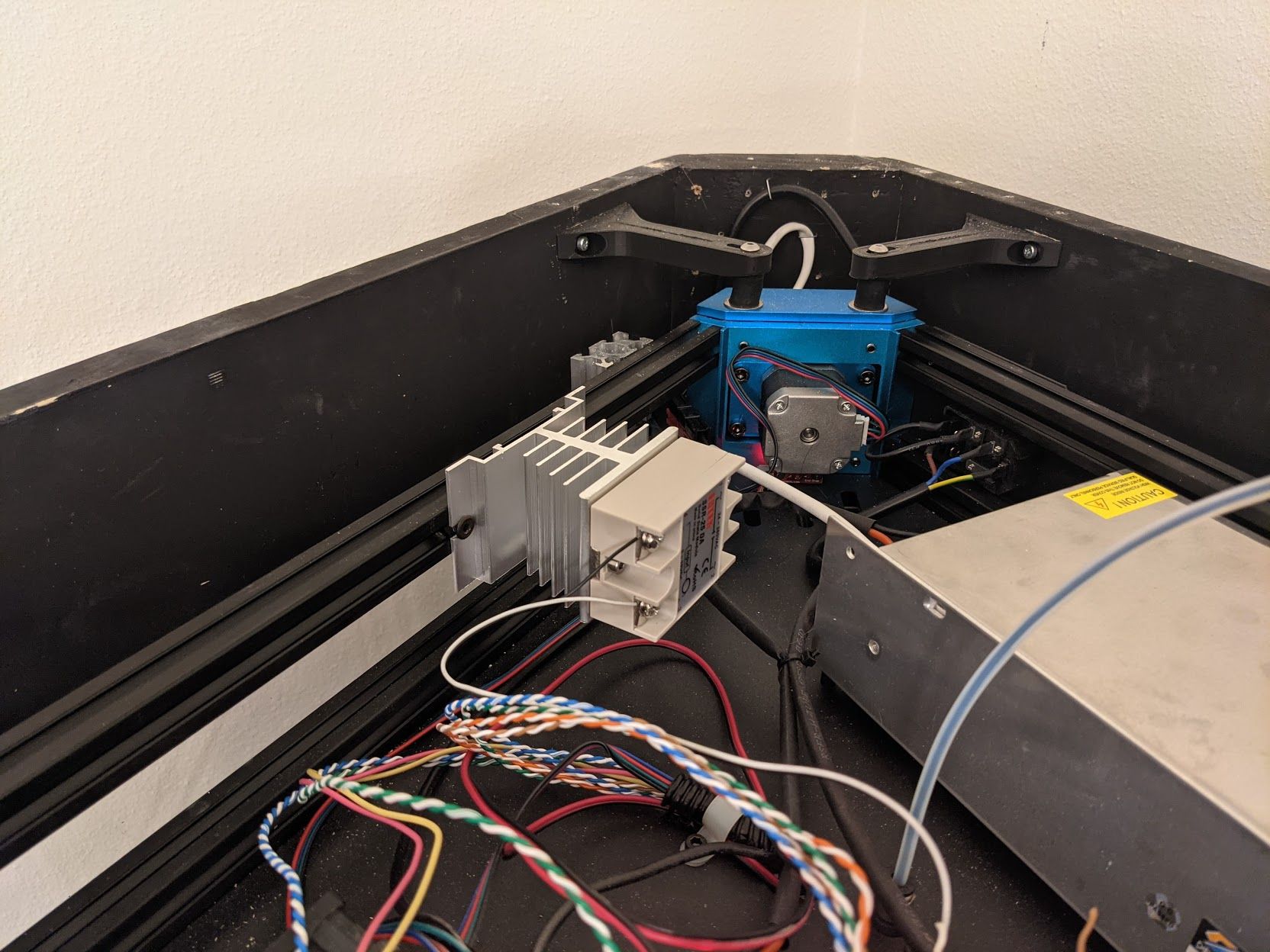

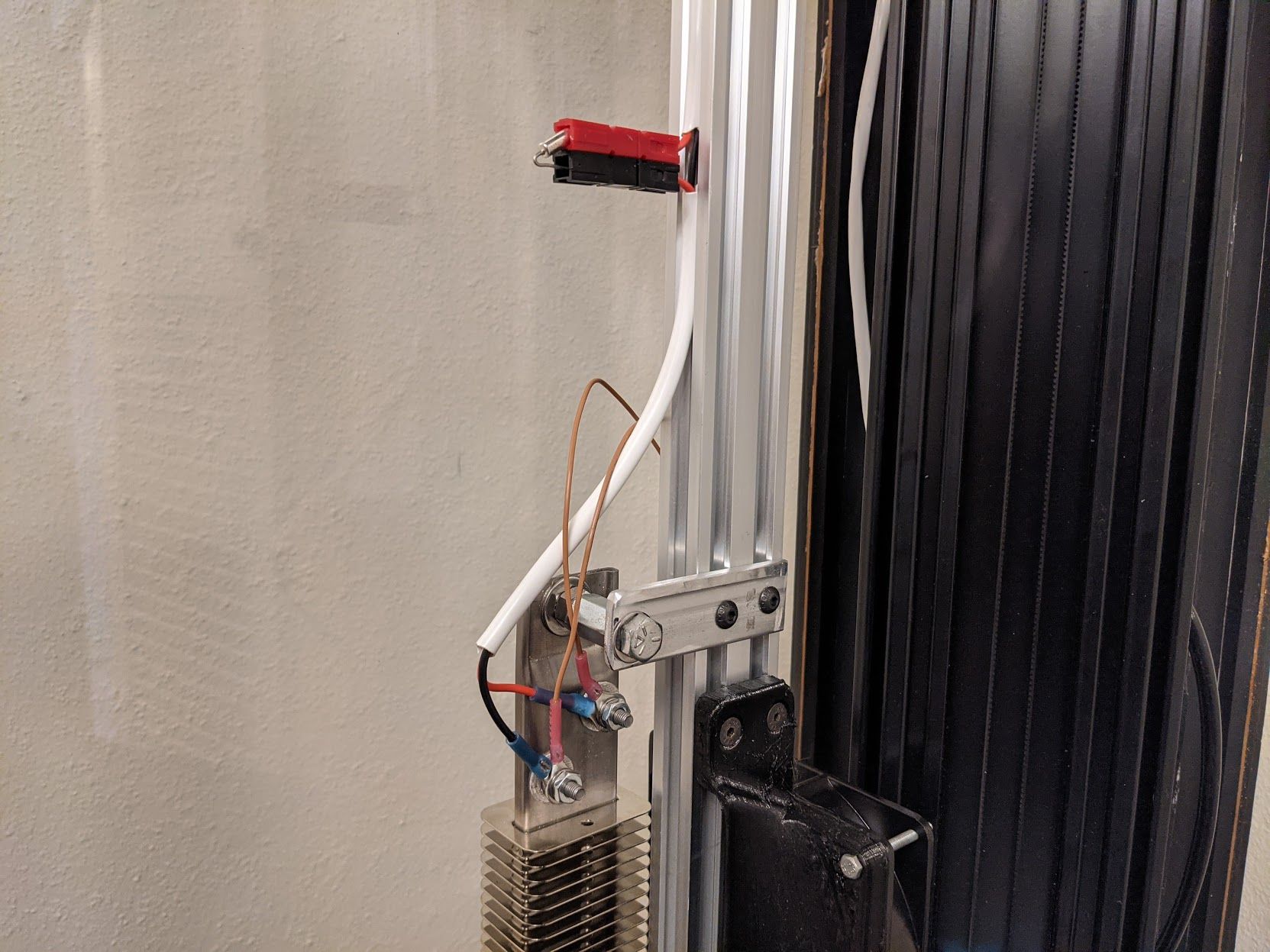

here's the SSR up top in the electronics area.

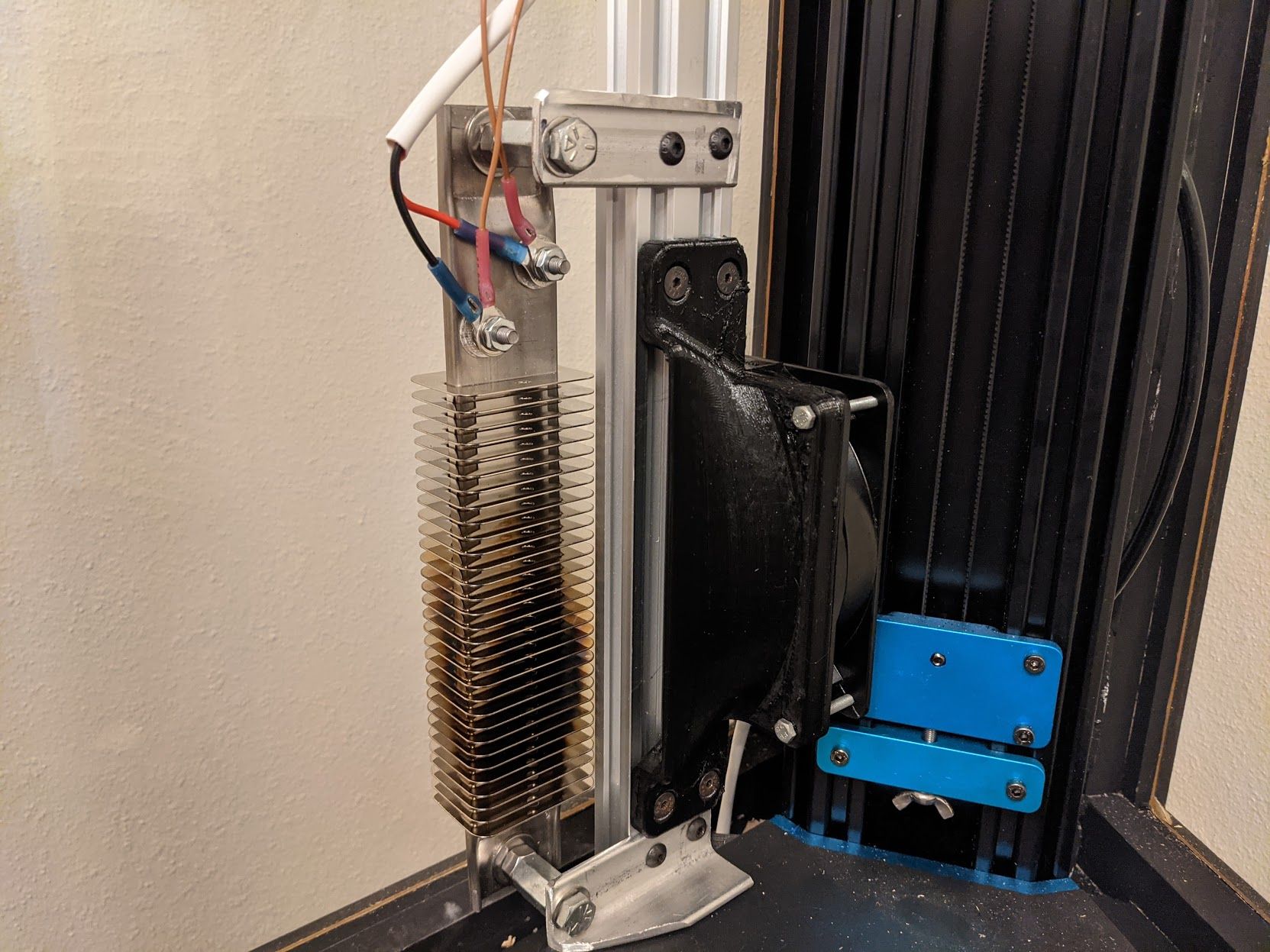

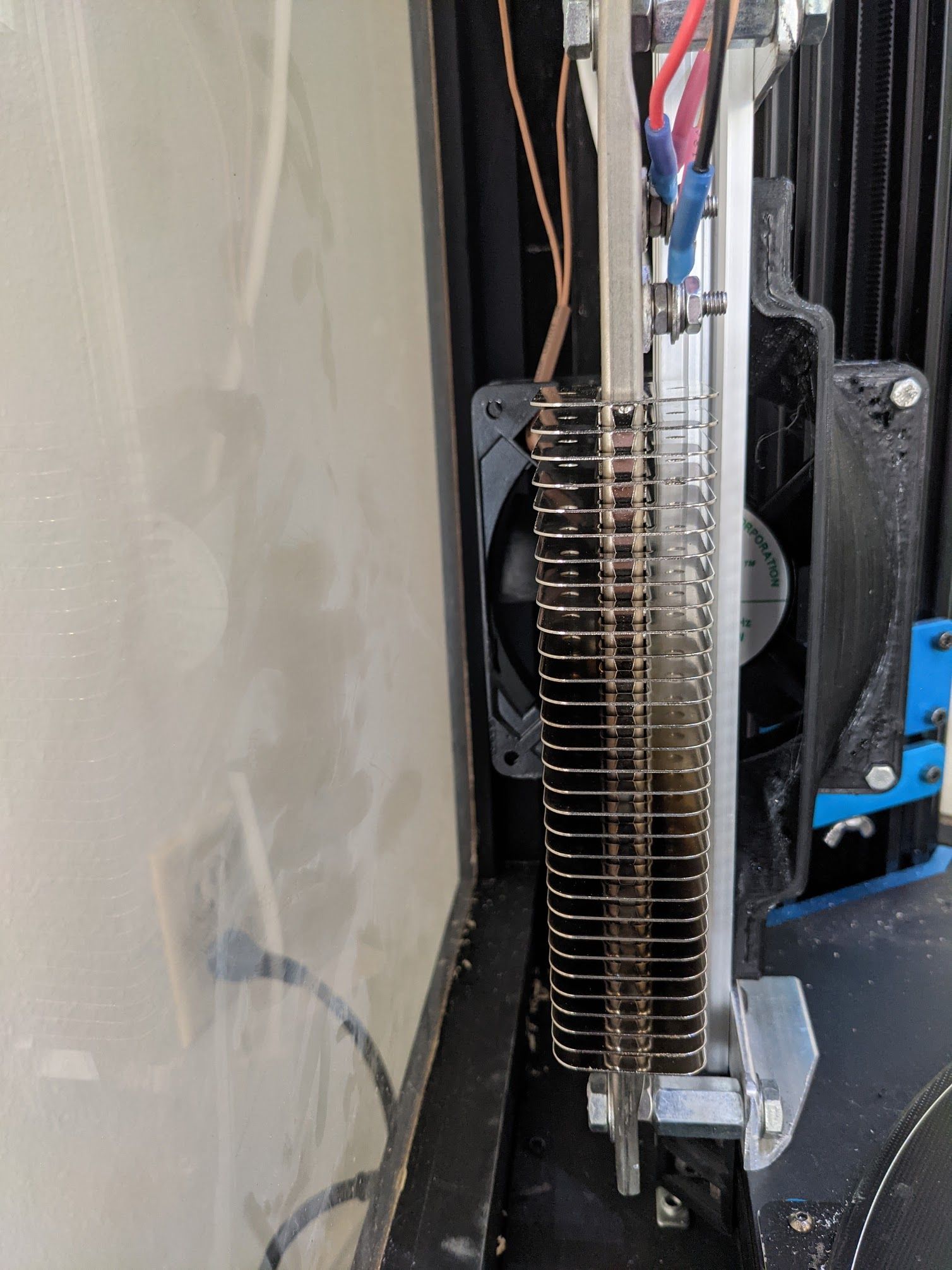

here's the heater and fan.

The brackets made acquaintance with a belt sander to clean up the bandsaw cuts, per CalvinX's suggestion.

and the tco

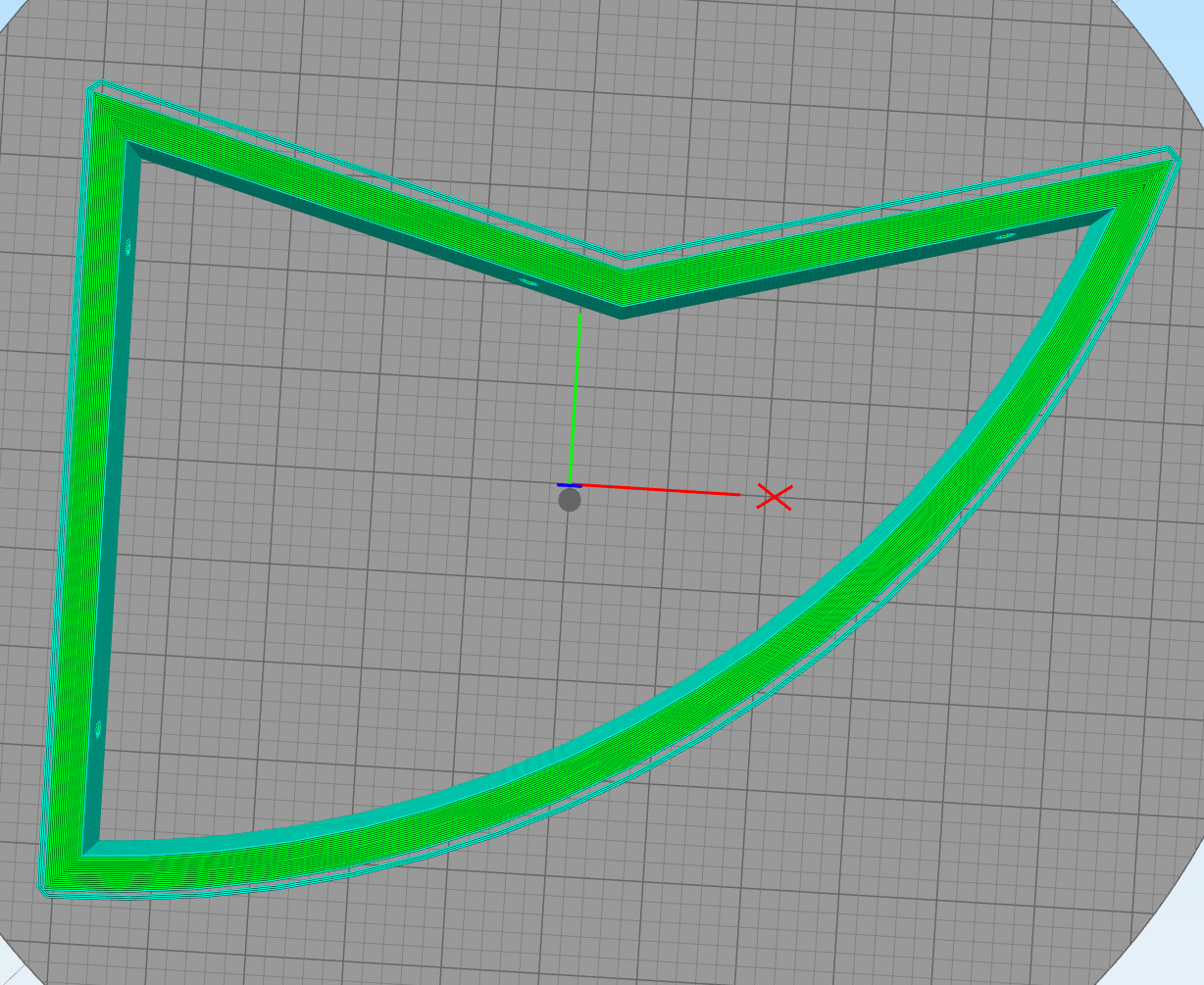

It's not exactly like the wiring diagram. I'd rather the TCO killed just the heater and not the heater and fan but that cabling would be much more complicated.Now I'm testing how much warp i get on an ABS print by printing something that would totally warp without a chamber heater. This V-shaped shelf bracket:

-

@oryhara I have a couple comments...

I would try to bring the wires up to the heater from below. That way if the fan quits the convection from the heater won't burn the insulation on the wires.

I wouldn't put so much plastic right around the TCO. I think you want that thing standing out in the open, not partially insulated by the connector. Also, if the fan quits the connector may melt due to hot air convection above the heater.

It's generally a good practice to put heatsink fins in a vertical orientation so that convection is maximized, but I guess the fan will take care of that problem as long as it is running.

How are keeping it from melting the back wall?

-

the leads on the TCO aren't long enough to move it further out of the anderson connectors.

Good idea on connecting the heater from below I'll get on that.

But i can't put the heater in another orientation or it won't fit(without compromizing build volume) unless I move it to the top of the enclosure.

The fan keeps the back wall cool by moving hot air off the heater so it doesn't make the back wall hot. It's really not that close despite the angle of the picture.

The TCO should trip before the back wall melts according its melting temp. Granted I haven't tested that scenario. It doesn't get more than 'warm' to touch. you can see my hand smudges on the outside of the window in this picture.

That's taken with my phone right against the plexiglass.

Though I guess if the fan fails then I might be in a pickle.My test print was a failure. It still warped. THen when I tried it with a brim it wouldn't even get the first layer down without peeling up.

I'll try again later with a PEI build surface instead of this whatever-material that came with the printer. Or maybe I'll put down some ABS juice. -

@oryhara I'd probably make a steel bracket to hold the TCO and if it needs longer leads, crimp (not solder) some wires to them and cover the wire with glass fiber insulation. The likelihood of it ever actually shutting down the heater is small, so using a connector isn't really necessary. You shouldn't be replacing the thing often or even at all.

Does the TCO you selected have any quality or safety certifications? I would/did use $1 each Cantherm parts from Digikey that are fully spec'd, just to be on the safe side.

Chamber heat and getting prints to stick to the bed are usually two different things. I use a clean PEI surface at 105C and ABS sticks well. If you're really worried about it letting go, a light application of glue stick ensures it absolutely will not come off the bed before the print is finished. There are as many means of assuring prints stick as there are people 3D printing.

The first few layers of a print should stay hot enough just by proximity to the hot bed plate, unless you're blowing relatively cool air across the print. Are you running the fan at full speed? That may be causing the print to cool quickly, shrink, and pull free of the bed. I try to minimize air movement inside the chamber- give it just enough movement to ensure that it gets to 50C everywhere and that's it. That's probably easier in my printer's architecture than yours. I use a 220V fan powered by 117VAC. It turns slowly and silently, moving just enough air to keep the heater from getting dangerously hot.

I haven't come up with a good way to cover the power attachment bolts on the heater yet. Someone sticking their hand inside the printer could get a bad surprise if they touch the bolts. I was thinking of covering the whole thing with a tube made of wire screen. That would allow air movement, protect the heater power bolts, and provide a convenient mounting place for the TCO. If someone smashed the screen they could short out the power to the heater but that would blow a fuse and shut it all off anyway. There's only so much stupidity you can protect against and still have a usable machine...

-

@mrehorstdmd Yea i learned my lesson soldering the TCO doesn't work. did that with the first one.

I bought a pack of ten off amazon so no safety certification at all. but at least I have spares.I tried a 220V fan initially but it wasn't 'cooling' the heater adequately. The back wall got too hot(for my comfort) and the thermistor didn't rise above 36C. So now its a 110V fan and yes it runs at full speed. 34CFM iirc the specs. Could be what was causing the warp since that happened 'downwind' of the general direction the fan is blowing. Maybe i'll move the whole assembly up a bit on that extrusion so its not blowing at the bottom of the print area there where it can cause problems with this object.

I agree first layer adhesion is a different issue. that's why im trying again after cleaning the build surface well. It hadn't been done in a while so probably might have contributed to the adhesion problem.

-

So I ended up getting a Amazon basic ceramic space heater and hooked it up to a ssr this thing works great