strange behavior from the thermistor

-

Hi,

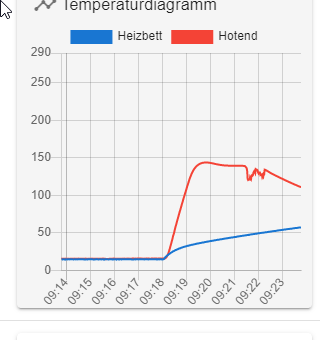

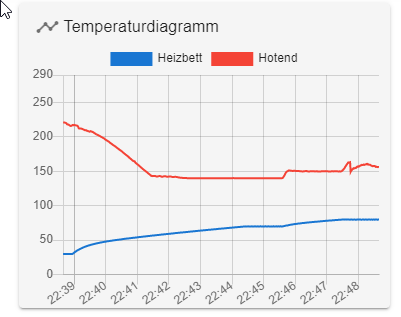

in the last time i get sometimes error heater fault this looks like shown in this picture

This shows the heat up only without moving anything on the printer. if this problem start it is impossible to heat up the extruder BUT when i restart the printer (m999) then it works without any problem this is what i don't understand. This problem is not Permanent in the last view weeks i had this issue three times.

This shows the heat up only without moving anything on the printer. if this problem start it is impossible to heat up the extruder BUT when i restart the printer (m999) then it works without any problem this is what i don't understand. This problem is not Permanent in the last view weeks i had this issue three times.

It seems that this happens when the printer was for longer time in idle

I am a little perplexed at the moment so far i know is it impossible to repair a thermistor or cable by a reset

3; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.4 on Sun Jan 05 2020 16:17:09 GMT+0100 (Mitteleuropäische Normalzeit) ;pwm auf ausgang 5 ; General preferences ;M555 P2 ; Marlin emulation G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"hypercube" ; set printer name M667 S1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S1 ; disable FTP M586 P2 S1 ; disable Telnet m554 P192.168.188.1 ;set gateway ; Drives M569 P0 S0 ; physical drive 0 = X goes backwards M569 P1 S0 ; physical drive 1 = Y goes backwards M569 P2 S1 ; physical drive 2 = Z goes forwards M569 P3 S1 ; physical drive 3 = Z goes forwards M569 P4 S1 ; physical drive 4 = Z goes forwards M569 P5 S0 ; physical drive 5 = nc M569 P6 S0 ; physical drive 6 = orbiter direct M569 P7 S1 ; physical drive 7 = E0 goes forwards bmg bowden M569 P8 S1 ; physical drive 8 = nc M569 P9 S0 ; physical drive 9 = g5 flex M584 X0 Y1 Z2:3:4 E6 ; set drive mapping orbiter M350 X16 Y16 Z16:16:16 E16 I1 ; configure microstepping with interpolation M671 X-1:390:-1 Y44:182:324 S3 F1.0 ; Leitspindeln links und rechts von der X-Achse M92 X80.43 Y80.43 Z797 E692 ;z790.6 E1175 ;E1420 ;E714 ;E2143 ;E2124 ;E1900 ;4246 ;2123 ; set steps per mm G5 Flex 2145 ohne dda 782.40 ;M92 X80 Y80 Z802.46 E4286 ; G5 Flex ; jerk ;M566 X600.00 Y600.00 Z300.00 E300 ;E150 ; set maximum instantaneous speed changes (mm/min) x/y 600 original M566 X300.00 Y300.00 Z50.00 E300 ;E300 last z = 150 xy=600 M203 X30000.00 Y30000.00 Z1200.00 E3600.00 ; set maximum speeds (mm/min) ;M201 X4000.00 Y4000.00 Z1000.00 E600 ;E120;E180.00 ; set accelerations (mm/s^2) x/y 2000 z 500 original M201 X1500.00 Y1500.00 Z200.00 e600 ;E600 last z= 250 xy=1000 ;19.3.2021, 18:30:31 m201 e3000 ;19.3.2021, 18:30:16 m566 e1500 ;19.3.2021, 18:29:55 m572 d0 s0.07 ; x/y Nema 17 42BYGHW811 2.5Amp 4800Torque ; Z Nema 17 Bipolar 1.8deg 65Ncm 2.1A 3.36V 17HS24-2104S ; E bondtech bowden Nema 17 Schrittmotor 1.7A 40Ncm 1.8 Deg M906 X2500.00 Y2500.00 Z2100.00 E500.00 I30 ; set motor currents ; g5 flex M913 X85 Y85 Z85 E100 ;E50 ;reduce stepperpower M84 S35 ; Disable motor idle current reduction ; Axis Limits M208 X-1 Y0 Z0 S1 ; set axis minima M208 X400 Y370 Z415 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop ;M574 Z0 P"nil" ; Z entstop frei geben m591 D0 P2 C"zstop" S1 ; Z entstop als filament sensor aktivieren M950 J1 C"duex.e5stop" ; Jnn = Input pin number (RRF 3.01RC2 and later only)/ C"name" Pin name(s) and optional inversion status. M581 P1 T2 S1 R1 ; P1 ; Z-Probe M558 P8 R1.5 C"^!zprobe.in+zprobe.mod" H5 F600 T12000 ;A3 S0.01; ;G31 P500 X0 Y0 Z-0.05; 2 ;Z-0.2 ;24 ; set Z probe trigger value, offset and trigger height G31 P500 X0 Y0 Z-0.075;-0.1; 2 ;Z-0.2 ;24 ; V6 mit HC2 M557 X0:383 Y0:361 P7:7 ;S75 ; define mesh grid ; Heaters ;https://duet3d.dozuki.com/Wiki/Calibrating_thermistor_and_PT1000_readings M308 S0 P"bedtemp" Y"thermistor" A"Heizbett" T100000 B3950 H12 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M140 H0 M143 H0 S115 ; set temperature limit for heater 0 to 100C M307 H0 B0 S1.00 ; disable bang-bang mode for the nozzle heater and set PWM limit M308 S1 P"e0temp" Y"thermistor" A"Hotend" T100000 B4725 C7.06e-8 H10 L-3;B4276 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M308 S2 P"mcu-temp" Y"mcu-temp" A"MCU" ; set virtual heater for MCU M143 H1 S290 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for the nozzle heater and set PWM limit ; Fans ;M950 F0 C"fan0" Q25500 ;H-1 ; create fan 0 on pin fan0 and set its frequency ;M106 P0 S0 H-1 C"Bauteilkühlung" ; set fan 0 value. Thermostatic control is turned on M950 F0 C"fan0" Q500;H-1 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 C"Bauteilkühlung" ; set fan 0 value. Thermostatic control is turned on M950 F1 C"fan1" Q500 T45 ;H1 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 C"Hotend" ; set fan 1 value. Thermostatic control is turned off M950 F2 C"fan2" Q250 ;H-1 ; create fan 2 on pin fan2 and set its frequency M106 P2 S0 H-1 F250 C"LED" ; set fan 2 value. Thermostatic control is turned off ; Tools M563 P0 S"Links" D0 H1 F0 ; define tool 0 ***** ;M563 P1 S"Rechts" D1 H1 F0 ; define tool 1 ***** G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets ;G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S22.0 R23.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ;auto save on loss of power M572 D0 S0.10;4 ;Pressure advance m593 F35 ;Dynamic Acceleration Adjustment ;m592 D0 A0.0122865 B-0.001164296 ;m592 D0 A0.003538564 B-6.21548E-05 ;m592 D0 A0.000719029 B0.001242184 ; nonlinear extrusion ;M572 D0 s0.02 ;extruder pressure advance T0 ; select first tool ;M207 S4.0 F4800 z0.8 ;Set retract length ;M290 S0.15 R0 ;; config-override.g file generated in response to M500 at 2021-04-07 21:28 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 R0.133 C1354.300:1354.300 D0.50 S1.00 V24.3 B0 M307 H1 R1.833 C322.931:213.622 D9.11 S1.00 V24.2 B0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 M486 S-18.4.2021, 11:28:18 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.2.2 running on Duet WiFi 1.02 or later + DueX5 Board ID: 08DGM-95BNL-MGPSJ-6J9FD-3SJ6N-K1W3Y Used output buffers: 3 of 24 (20 max) === RTOS === Static ram: 23460 Dynamic ram: 74348 of which 80 recycled Never used RAM 14192, free system stack 115 words Tasks: NETWORK(ready,185) HEAT(blocked,294) DUEX(blocked,31) MAIN(running,382) IDLE(ready,20) Owned mutexes: WiFi(NETWORK) === Platform === Last reset 02:04:05 ago, cause: software Last software reset at 2021-04-08 09:24, reason: User, GCodes spinning, available RAM 14228, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU temperature: min 29.3, current 40.0, max 40.5 Supply voltage: min 24.0, current 24.3, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: position 15603, standstill, SG min/max 0/171 Driver 1: position -15764, standstill, SG min/max 0/173 Driver 2: position 8173, standstill, SG min/max 0/1023 Driver 3: position 0, standstill, SG min/max 0/317 Driver 4: position 0, standstill, SG min/max 0/1023 Driver 5: position 0, standstill, SG min/max not available Driver 6: position 0, standstill, SG min/max 0/1023 Driver 7: position 0, standstill, SG min/max not available Driver 8: position 0, standstill, SG min/max not available Driver 9: position 0, standstill, SG min/max not available Driver 10: position 0 Driver 11: position 0 Date/time: 2021-04-08 11:28:16 Cache data hit count 4294967295 Slowest loop: 136.93ms; fastest: 0.20ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 2.7ms, write time 45.2ms, max retries 0 === Move === DMs created 83, maxWait 311257ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 2530, completed moves 2530, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 6], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.3 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 123.01ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 4 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.25 WiFi MAC address 2c:3a:e8:0b:06:33 WiFi Vcc 3.44, reset reason Turned on by main processor WiFi flash size 4194304, free heap 24376 WiFi IP address 192.168.188.36 WiFi signal strength -52dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0 === Filament sensors === Extruder 0 sensor: ok === DueX === Read count 1, 0.01 reads/min -

@siam this kind of behaviour is a common failure mode for thermistors. Not necessarily the exact failure you are seeing but the rapidly changing temperature swings that are much faster than what the heated mass could reasonably swing if the supply current was stopped and restarted. I am specifically talking about the quick sharp excursion in temperature and not the slower overall temperature change.

You would likely see a slow deterioration/worsening with time.

Get yourself a new thermistor. -

in this case i will try a new one thanks for your assistance

-

That was not the solution i have changed the Hotend and Thermistor after this i was able to print. Now i wanted to Start a new Print and i get always the error :

8.4.2021, 20:50:50 Error: Heater 1 fault: temperature rising much more slowly than the expected 1.1°C/sec 8.4.2021, 20:50:16 Error: Heater 1 fault: temperature rising much more slowly than the expected 1.3°C/sec 8.4.2021, 20:49:39 Error: Heater 1 fault: temperature rising much more slowly than the expected 1.4°C/sec 8.4.2021, 20:47:28 Error: Heater 1 fault: temperature rising much more slowly than the expected 1.4°C/sec 8.4.2021, 20:45:07 Error: Heater 1 fault: temperature rising much more slowly than the expected 1.2°C/sec 8.4.2021, 20:44:19 Error: Heater 1 fault: temperature rising much more slowly than the expected 1.3°C/sec 8.4.2021, 20:43:30 Error: Heater 1 fault: temperature rising much more slowly than the expected 1.3°C/sec 8.4.2021, 20:42:49 Error: Heater 1 fault: temperature rising much more slowly than the expected 1.4°C/secWhat surprises me is that the expected temperature is constantly different ? The next thing is that this errors occur the most times at the same Temperature, although the temperature continues to rise as you can see here in this Video.

show video -

@siam, did you run heater tuning after you changed the thermistor?

Did you use the correct data points for your new thermistor (in case it was different from the previous version) -

@jens55 said in strange behavior from the thermistor:

@siam, did you run heater tuning after you changed the thermistor?

yes i have done

Did you use the correct data points for your new thermistor (in case it was different from the previous version)

The new thermistor is The same type as the old one

-

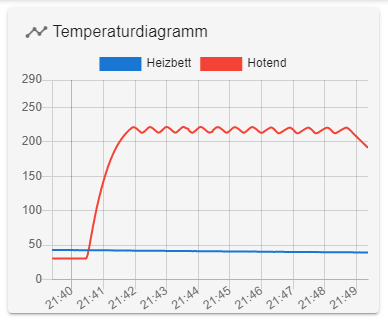

@jens55, ugh, that is one ugly temperature graph! The good thing is that you don't have the sharp spikes and drops you had before.

Go ahead and see what re-tuning the hot end will do for you. -

Hmmmm .... how did the tuning process go? Anything unusual? If you just turn on the hot end and let it sit without printing, what does the temperature do ?

-

@jens55 said in strange behavior from the thermistor:

@jens55, ugh, that is one ugly temperature graph! The good thing is that you don't have the sharp spikes and drops you had before.

Go ahead and see what re-tuning the hot end will do for you.Retuning is running now and the hotend has reached 220 C° ....

Here the log info

8.4.2021, 21:48:51 Auto tuning heater 1 completed after 3 idle and 10 tuning cycles in 510 seconds. This heater needs the following M307 command: M307 H1 R1.294 C288.4:230.7 D4.05 S1.00 V24.3 Send M500 to save this command in config-override.g 8.4.2021, 21:45:56 Auto tune starting phase 3, fan on 8.4.2021, 21:43:45 Auto tune starting phase 3, fan off 8.4.2021, 21:41:52 Auto tune starting phase 2, heater settling 8.4.2021, 21:40:25 Auto tune starting phase 1, heater on 8.4.2021, 21:40:20 M303 T0 S220 Auto tuning heater 1 using target temperature 220.0°C and PWM 1.00 - do not leave printer unattendedand here a picture of the process

and now it seems my printer will be kidding me i have save the settings and loaded with m501 and now i get this message:

8.4.2021, 21:50:23 M501 Warning: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 205C -

@siam, I believe the thermistor is working well but that something is messed up in the setup parameters. Unfortunately I do not know config files well enough to help but I am sure that before long somebody else will pop up with the answer.

The warning that you are getting is for the bed heater and not the nozzle heater. Maybe verify that the correct parameters ended up in the right file as it is odd to get a bed heat warning when you were messing with the nozzle temperature. -

@jens55 said in strange behavior from the thermistor:

Hmmmm .... how did the tuning process go? Anything unusual? If you just turn on the hot end and let it sit without printing, what does the temperature do ?

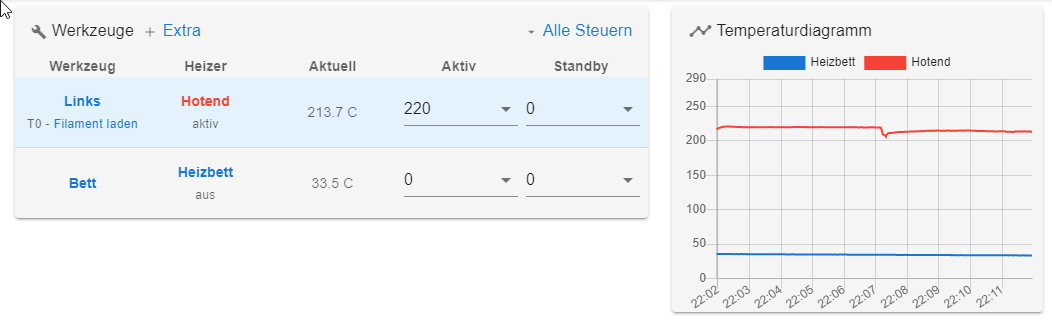

after the pid tuning i can reach 220 c° without error and the temperature is stable range 219.8 - 220.1 C°

-

@siam, so everything is working now?

-

@jens55 said in strange behavior from the thermistor:

@siam, I believe the thermistor is working well but that something is messed up in the setup parameters. Unfortunately I do not know config files well enough to help but I am sure that before long somebody else will pop up with the answer.

The warning that you are getting is for the bed heater and not the nozzle heater. Maybe verify that the correct parameters ended up in the right file as it is odd to get a bed heat warning when you were messing with the nozzle temperature.Ok your right is heater 0 not 1

-

@jens55 said in strange behavior from the thermistor:

@siam, so everything is working now?

happy too early ....

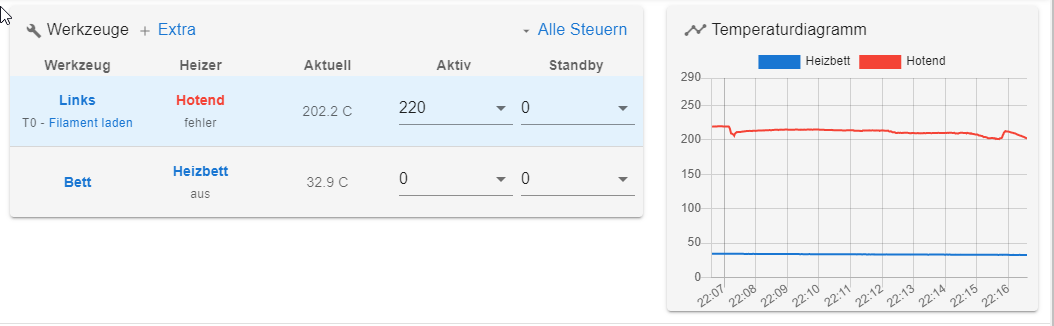

The temperature goes now slowly down and is no longer highly regulated

and now heater error ....

8.4.2021, 22:15:17 Error: Heater 1 fault: temperature excursion exceeded 15.0°C (target 220.0°C, actual 203.9°C) -

@siam, dang, I thought we had it sorted

Is it dropping while you are printing or just when it is sitting there? If it happens while you are printing then try without printing. Do you have the part cooling fan on maybe? try without the part cooling fan.

Is it dropping while you are printing or just when it is sitting there? If it happens while you are printing then try without printing. Do you have the part cooling fan on maybe? try without the part cooling fan.

I am really grasping at straws here and am quickly running out of things to try ...... -

@jens55 said in strange behavior from the thermistor:

dang, I thought we had it sorted Is it dropping while you are printing or just when it is sitting there? If it happens while you are printing then try without printing.

Until this evening i was able to print without problems but since a couple of hours is printing impossible. Because the printer reaches not the print temperature anymore

Do you have the part cooling fan on maybe? try without the part cooling fan.

part cooling is off

I am really grasping at straws here and am quickly running out of things to try ......

that's my problem too !!

-

@siam, the only thing that is left is the possibility of an intermittent power connection to the heater. Either from flexing due to the printhead moving about or, if the power cables are interrupted anywhere for a connector, from a bad connector.

Try disconnecting and re-installing all connectors (including the one on the Duet board). Bad connections can develop over time and produce a bit of resistance that in turn will reduce power delivered to the heating element. -

@jens55 it seems that i have found my work over the weekend .... in the hope of finding the fault