Chamber heater plan

-

@macguyver Those look pretty good!

-

@mrehorstdmd I like the options, though you have to be careful with them all. There are however the ultra-cheap options I toyed with such as THIS . In the end I eventually stumbled upon the Stego and snagged one up off Ebay for $50. About the same price as anything I would have put together, but much simpler to install and get back to printing in the winter. Though I have a feeling I might need a little more power, like THIS

-

So my new plan is to use the bolt-mount heater and 220V fan like @mrehorstdmd setup. I ordered them yesterday before @macguyver 's post about stego heaters, which I agree would be the 'proper' way to heat my enclosure.

I'm curious now how to place them.

it's a delta, so the bottom is always where the print starts. I know heat rises, so bottom is the best placement.

My question is fan placement. Should it aim at the print, the 0,0,0 coordinate, center of the build area?

or I could point it along the side of the enclosure, basically perpendicular to being aimed at 0,0,0, and hope that the air will circulate around without directly blowing on my part.Is there conventional wisdom on direct vs indirect hot air blowing on a print? or does the low CFM from using a 220V fan at half its rated voltage mean where it aims is moot?

-

@oryhara I think blowing across the part would be counter productive. The air is still going to be colder than the part so I would think it would still cool it down faster and risk warping/cracking.

You may need a more powerful fan depending on how low the CFM is on what you have. My enclosure is almost air tight. The heatbed heats the air ABOVE the heatbed 20+ degrees over ambient, but does next to nothing for the air below it. With the heater above you may only heat the enclosure as far down as the fan can push it down, before it starts rising. You may want to do some tests moving a thermistor to various spots in the enclosure to see if it heats evenly.

-

@oryhara said in Chamber heater plan:

Is there conventional wisdom on direct vs indirect hot air blowing on a print? or does the low CFM from using a 220V fan at half its rated voltage mean where it aims is moot?

As @macguyver says, moving air will cool the part faster than stationary air (and its a proportional relationship, move the air twice as fast, cool twice as much).

Given the large vertical dead space in a delta your concern seems reasonable though. The goal is to keep the polymer at or close to its glass transition temp.

Your choices are probably:- Pure convection, but run hotter, so the dead space is actually hotter than you want, but the build volume is at the target temp. (With the risk that the top of the space could get really really hot.

- Fan. But run hotter so that the air is at or close to the target temp of the polymer. The fan should give you a more uniform temp, and you might not need to run that much hotter.

Direct is going to be more of a problem, as it will require the highest temp, and unless it heats up the whole enclosure doesn't really solve the problem (non-uniform rate of cooling).

And as others have said (and I have built and tested) IR heaters are not the right solution. The primary heat loss from the part is convection, so you need to heat the air.

You can use IR, but it takes a lot more power! -

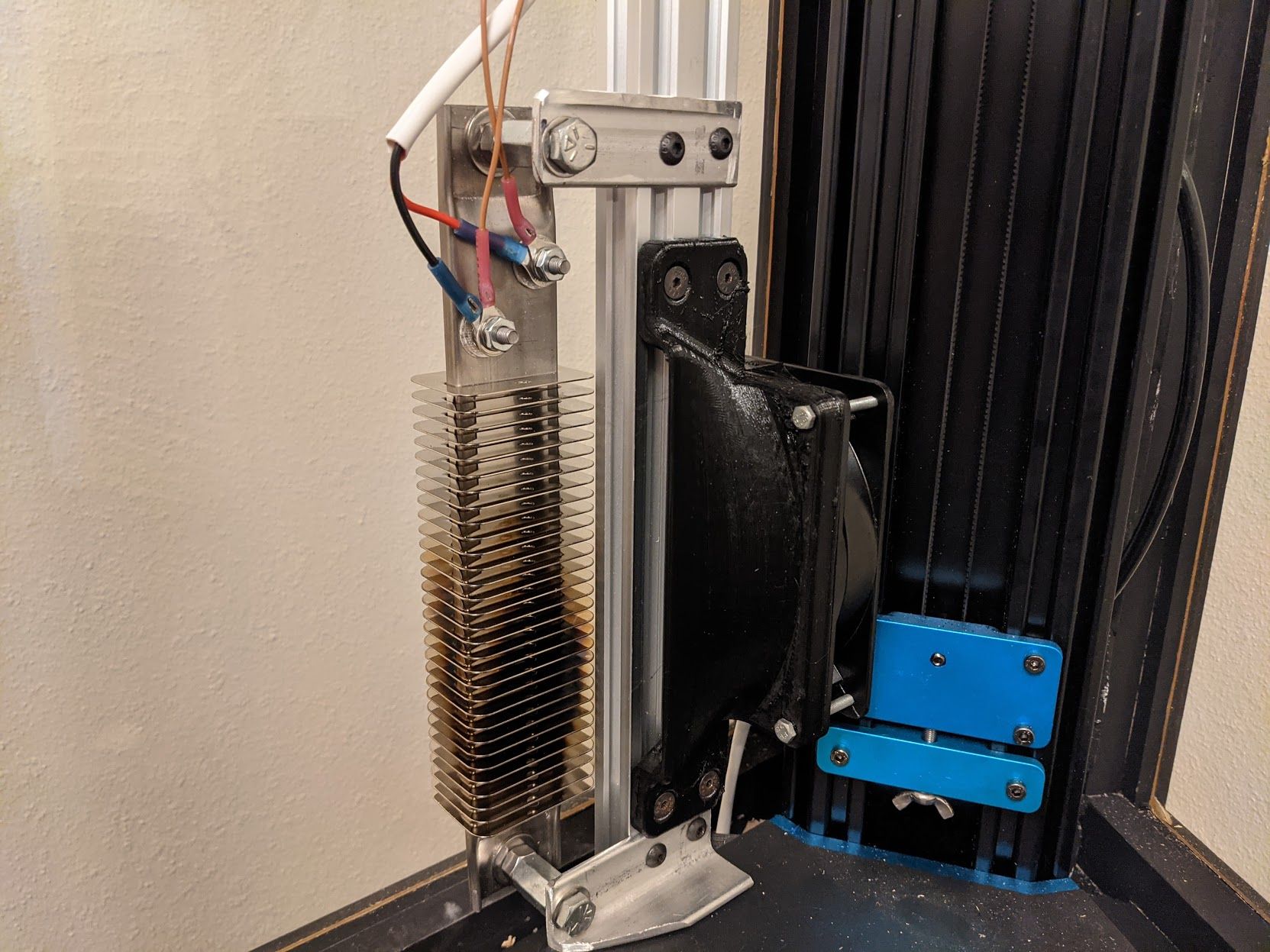

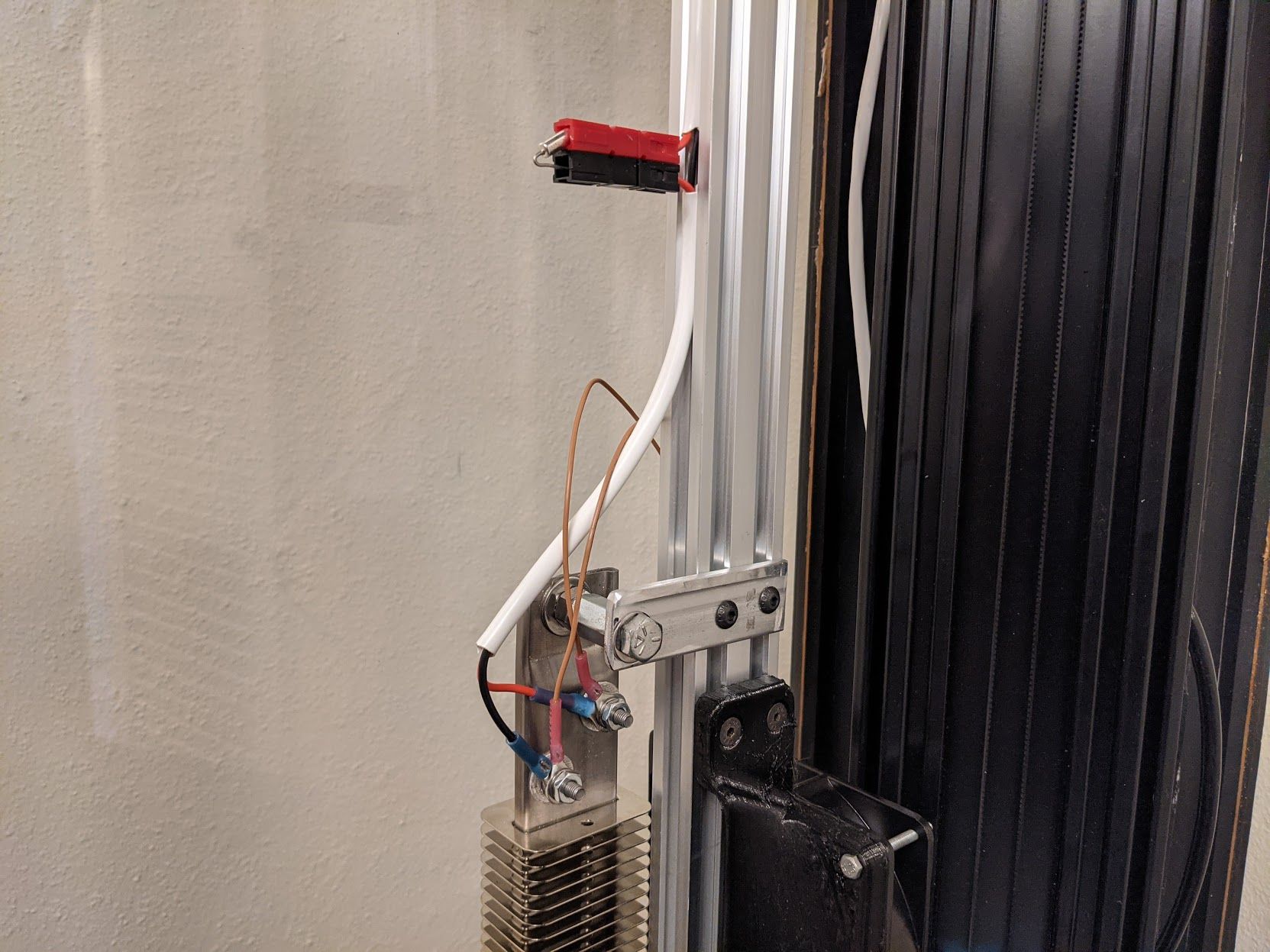

I've got the heater and fan mounted in my enclosure. The effector just misses the brackets there at the edge of its travel.

Now I just need to wire them up.

-

@oryhara said in Chamber heater plan:

I've got the heater and fan mounted in my enclosure. The effector just misses the brackets there at the edge of its travel.

Now I just need to wire them up.

Ever heard of a file ?

-

@oryhara I can't figure out what I'm looking at. What kind of fan/duct is that? It looks like the heater is very close to the side wall (if that's clear PC sheet there).

-

@CaLviNx

I'll make it pretty after i make it work. if it don't work it doesn't matter how pretty it looks.@mrehorstdmd It's not that close. about 50 or 60 mm away. The picture isn't at the best angle. and the fan duct is just to try and keep the fan from blowing right on the part.

Update: I've got it wired up. now trying to get the heater tuned. The problem is the temp rise is so slow that m303 fails to detect any rise at all. I set the dead time to 60 seconds but i think i need to change the gain so the m303 will work.

-

@oryhara said in Chamber heater plan:

@CaLviNx

I'll make it pretty after i make it work. if it don't work it doesn't matter how pretty it looks.@mrehorstdmd It's not that close. about 50 or 60 mm away. The picture isn't at the best angle. and the fan duct is just to try and keep the fan from blowing right on the part.

Update: I've got it wired up. now trying to get the heater tuned. The problem is the temp rise is so slow that m303 fails to detect any rise at all. I set the dead time to 60 seconds but i think i need to change the gain so the m303 will work.

The old saying goes: if it looks right, it usually is right.

Pride in your work and doing the best you can even for prototyping is just good practice.

-

@CaLviNx form follows function

like i said I'll make it pretty when it works.

which it doesn't at the moment. I can't get M303 to run because it heats so slowly, even with the bed at 100 degrees.@mrehorstdmd I'm curious how you got your chamber heater model to work, given you said it takes 20 minutes to get to 50C

-

still no joy with M303 but with a gain set nice and low M141 seems to be working ok. I set the model parameters manually per the instructions:

https://duet3d.dozuki.com/Wiki/Tuning_the_heater_temperature_control#Section_Setting_the_model_parameters_manuallyso now I get to make it pretty.

@CaLviNx you said something about a file? what needs filing?

you want I should round off the corners of the mounting bracket? -

@oryhara I'm pretty sure I've got the chamber heater running in bang-bang mode. I'll check the config file when I get home.

-

Yea bang-bang mode with manually-configured heater model worked ok.

Well I say ok. The firmware ran it without complaint. But 20 minutes later and my chamber temp didn't read more than 36degrees. Running both bed and heater I expected more.

And the clear panel nearest the heater element got too hot to touch and started to bow inward. Probably is too close.

I think I need a more powerful fan on the heater element. the 220V is moving but probably not enough if its radiating heat like that and not getting hot air to the thermistor.Also my thermistor is in a metal casing which might be throwing off the reading by acting as a heat sink. maybe? I'm no expert. I bought this: https://www.amazon.com/DROK-Waterproof-Temperature-Thermistor-Transimitter/dp/B01MR37GOQ/ref=sr_1_6?dchild=1&keywords=thermistor&qid=1608467027&sr=8-6

for my chamber heater sensor. maybe I should have bought a bare thermistor.Im going to order a 110V fan and see if that improves the chamber heater performance. 'cooling' the heater element faster should raise the ambient air temp in my enclosure faster. until they reach equilibrium. This base on my imperfect memory of high school science class. Of course there are losses to the air outside my enclosure based on the insulation effectiveness. My 1/8" clear plexiglass panels are not as good as corrugated ones. And my enclosure isn't perfectly airtight. There are holes for cabling.

-

@oryhara I use a bare thermistor to check chamber temperature. Those canned things are good if you need to mount them in a heater block, but in air they are going to slow down the readings because all that mass takes time to heat up. The little glass bead type thermistors have very low mass so they follow temperature changes quickly.

This is the chamber heater config I use:

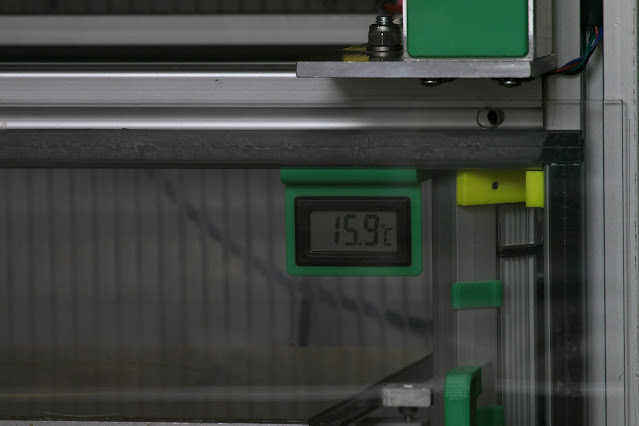

M307 H2 A11 C99000 D2000 B1I mounted the chamber thermistor about half way up the Z axis:

I installed a little $5 LCD thermometer in my printer, near the xy stage to monitor chamber/ambient temperature at a glance, even when the printer is off.

-

This post is deleted! -

It works. Took about 23 minutes to reach 50 degrees.

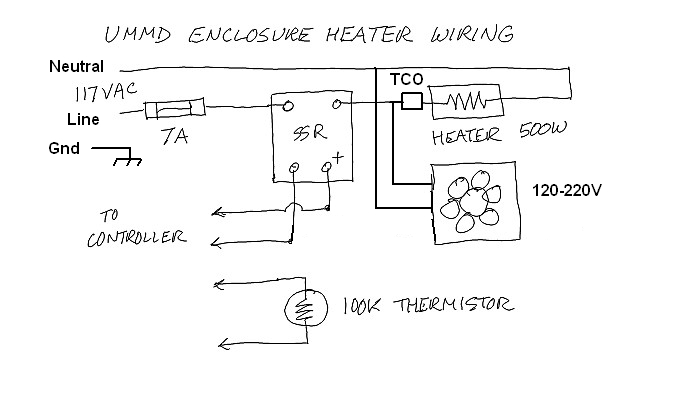

I want to thank everyone here for their help.In case anybody wants to repeat my success, here is what I did:

this heater element:

https://www.mcmaster.com/3575K411/

with this fan:

https://www.mcmaster.com/1976K95/

this SSR:

https://www.amazon.com/gp/product/B07FVR37QN/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

this thermistor:

https://www.amazon.com/gp/product/B07V6YBFSY/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

and this TCO:

https://www.amazon.com/gp/product/B07JM2DB67/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1Wired them up per this diagram

@mrehorstdmd said in Chamber heater plan:

Wiring:

-

@oryhara Photo of the assembly?

-

@mrehorstdmd said in Chamber heater plan:

@oryhara Photo of the assembly?

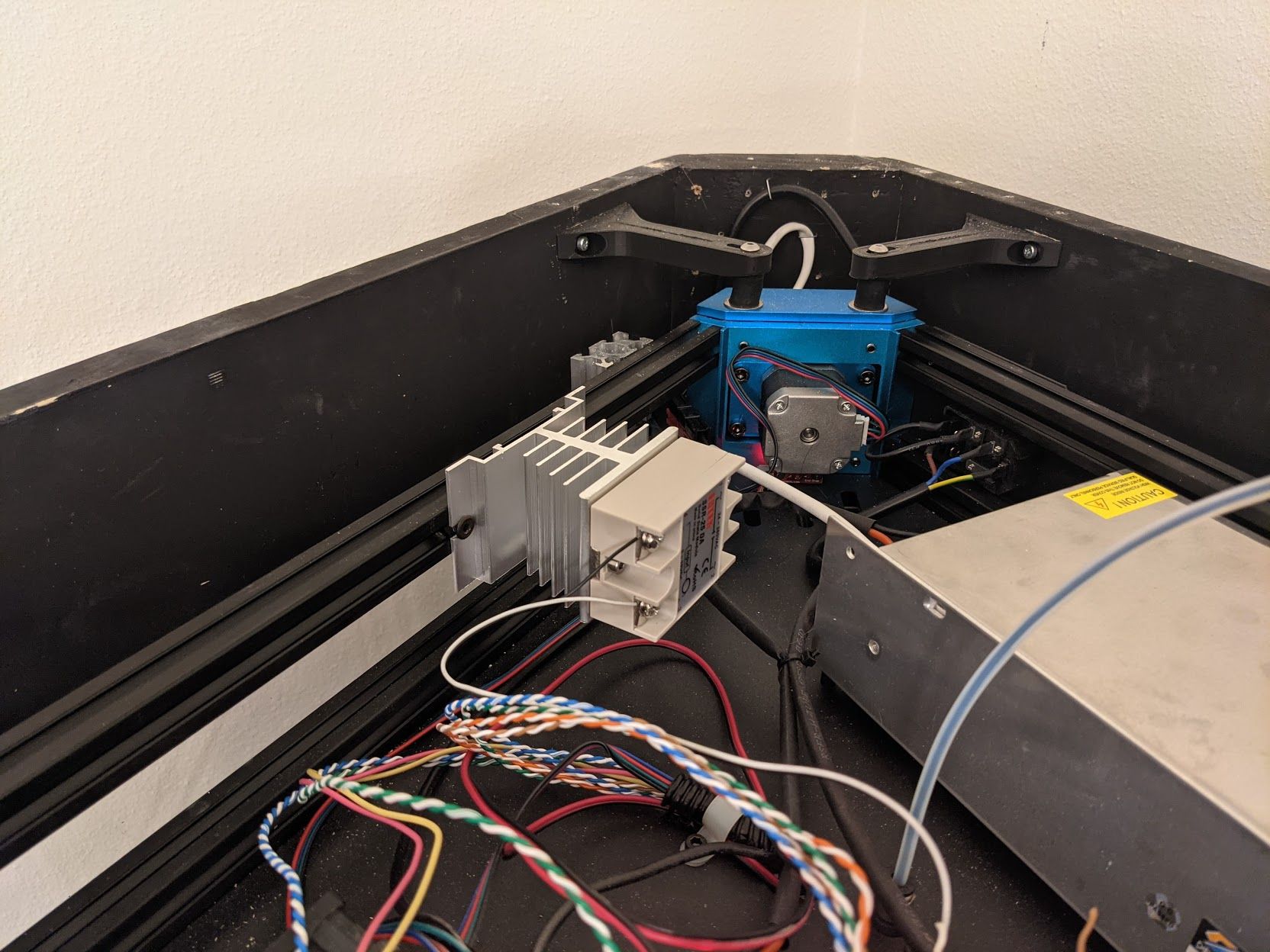

here's the SSR up top in the electronics area.

here's the heater and fan.

The brackets made acquaintance with a belt sander to clean up the bandsaw cuts, per CalvinX's suggestion.

and the tco

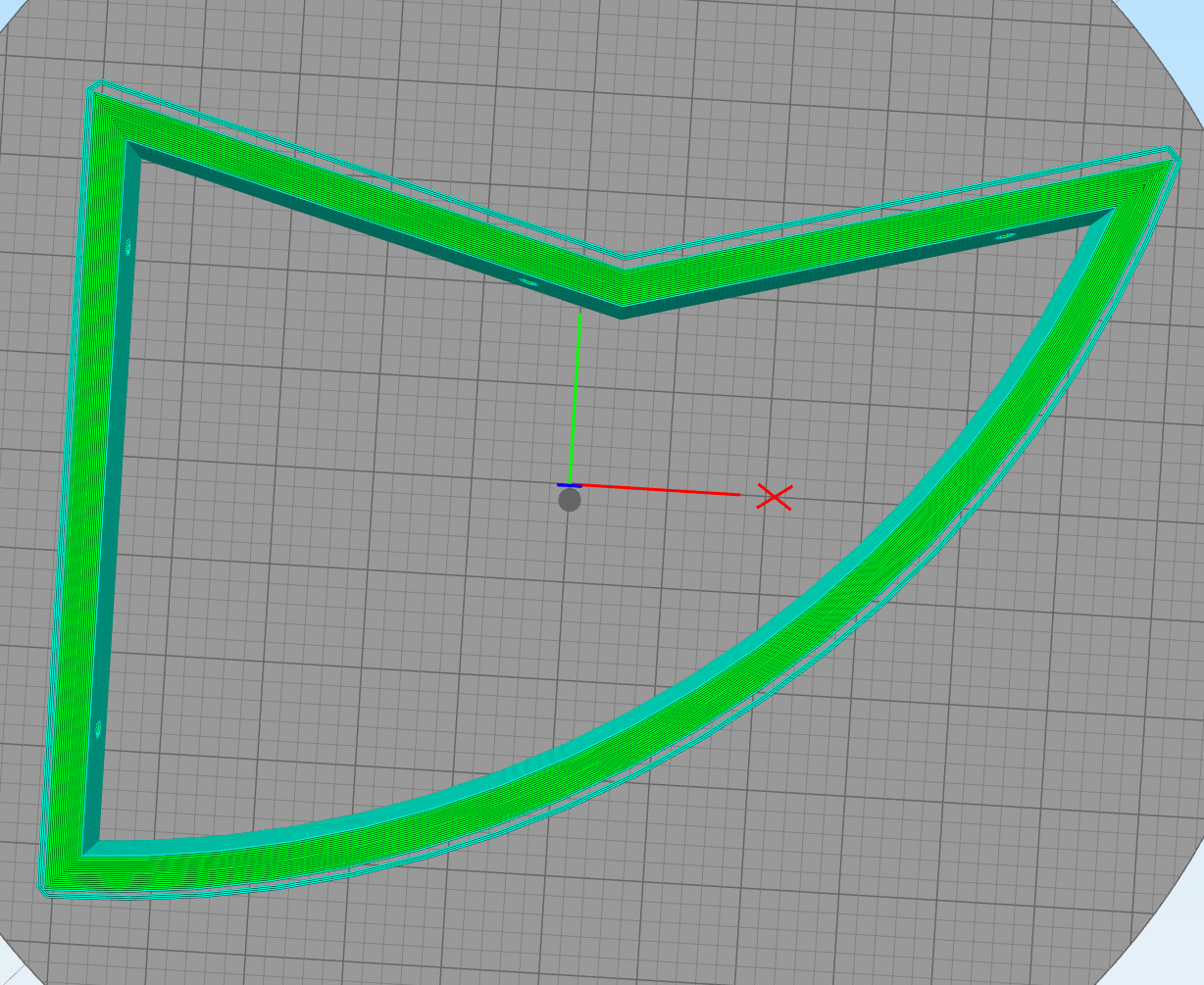

It's not exactly like the wiring diagram. I'd rather the TCO killed just the heater and not the heater and fan but that cabling would be much more complicated.Now I'm testing how much warp i get on an ABS print by printing something that would totally warp without a chamber heater. This V-shaped shelf bracket:

-

@oryhara I have a couple comments...

I would try to bring the wires up to the heater from below. That way if the fan quits the convection from the heater won't burn the insulation on the wires.

I wouldn't put so much plastic right around the TCO. I think you want that thing standing out in the open, not partially insulated by the connector. Also, if the fan quits the connector may melt due to hot air convection above the heater.

It's generally a good practice to put heatsink fins in a vertical orientation so that convection is maximized, but I guess the fan will take care of that problem as long as it is running.

How are keeping it from melting the back wall?