-

@jay_s_uk said in MPCNC and Duet 2 Wifi Setup:

Once edited, the interface will ask you if you want to reboot the board. The config.g will then get loaded at reboot.

This is exactly what I was looking for. Thank you!

Do i need to tell my CAD/CAM software that I have dual endstops? Or does that only work for homing? -

The firmware handles it all so set and forget

-

Ah i see. So if I am understanding it right:

- I am currently setting up my MPCNC with RAMPS board with Dual endstops where the marlin firmware handles everything.

- If I swap RAMPS with Duet board, I have to plug in motors and endstops correctly on Duet, configure the config.g file correctly with Duet board to make it aware of the endstop configuration, and then RepRap firmware will handle it.

- The same g-code that was operational on Marlin framework, will work on the RepRap firmware without any change.

Is my reasoning correct?

-

@mtcl 1 and 2 is correct.

The 3rd one probably not as most of the gcode for marlin is in mm/s whereas reprapfirmware firmware is in mm/min.

There may be some gcode that is also not compatible.

What are you using to generate your gcode? -

Till now I have only used ultimaker cura for my 3d printer to create g code. I haven't used cnc before.

-

I'm enjoying my MPCNC quite a bit, but opted not to use a Duet for it. I did most of the configuration though. (Edit: Was going to include my homex.g, but realized that I still have it set up for older firmware, not the latest, which is a little different.)

First off, if you want to use the dual endstops (Which I like, auto-squaring the machine is a good thing) you will need to define a couple extra endstops. If not, wiring both motors for the X and Y in series makes it really simple.

My solution when I was looking at the Duet was to separate out the 2 X and Y motors to separate axes for the homex.g and homey.g (and homeall.g) files to U and V (I think) axes, then redefine the X and Y drives back to the 2 motors each after.

The G code for machining will be fine, though I stopped before I got to the CNC work coordinate stuff on the Duet. Assuming that your machine is set so that your work coordinates are defined before you start cutting the same gcode for cutting will work as expected.

-

My MPCNC is still printing, 3 more days to go.

May I please know why you did not use duet for it? Any specific reason? I am new to all this so I want to learn from everyone's experiences as much as I can.

Also, what did you use eventually? I also have a RAMPS 1.4 board with me with drv8825 drivers on them. I noticed that motor makes a humming sound when I use RAMPS board though.

I also have a creality board from ender 5 v1.1.4, not sure if it is any better than RAMPS or not. Any suggestions/comments are highly appreciated.

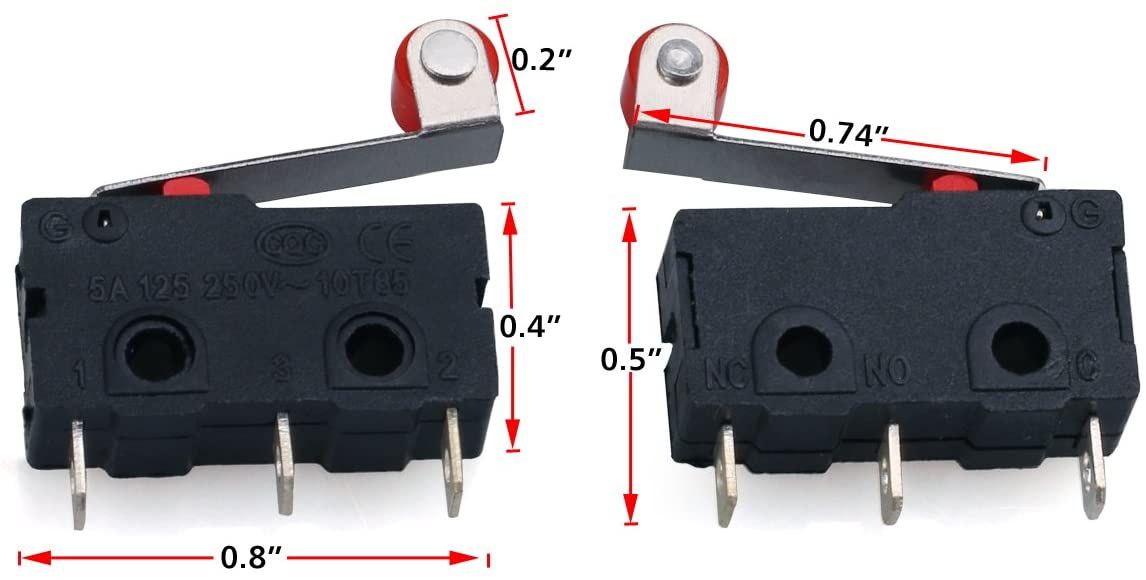

On the side note, I have the regular endstop from AMAZON that looks like this

Do you know how I would connect this to DUET board? Do I need all three terminals to be connected on the board, or only two?

-

The duet range of boards aren't fully real-time in the way gcode is processed.

The file gets read and the gcode gets buffered, so if you send a pause request, this queue has to be emptied before the pause takes place.

Depending on spindle etc as well, it doesn't get full feedback.

Something like a cheap breakout board for linuxCNC has RS485 support so as well as setting the RPM of the spindle, the board gets fed back the actual RPM so adjustments can be made. The downside of these boards is you need a PC next to your CNC to have control.

Also, most CNC machines operate at higher voltages than the duet range of boards. 12v-24v is perfectly fine for 3D printing but as CNC is typically higher speeds, higher voltages have to be used to keep the torque high. Therefore, it can be seen as a bit of a waste to use a duet 2 just to run external drivers (assuming you need larger drivers etc).You won't gain anything by using the creality board.

And for those endstops, use the two outer pins.

-

Well, my reason for not using the Duet came down to 2 reasons.

-

I had an MKS Gen L board with DRV8825 drivers in it. The board is cheap, about 1/10 the price of a Duet Wifi, (Maybe 1/5 including the full graphic controller) and

-

I could download a pre-configured Marlin distro for the MPCNC, no guesswork required, and then if things eren't going right, I could eliminate software because I'd be using a "stock standard" distribution.

Though I'm not absolutely adverse to re-inventing the wheel, I figured that I could swap it over later if need be. There are some configuration items that I can do on the Duet that I cannot do with the RAMPS/Marlin, so I might do so. As it happens, though, I fried my printer Duet by running over the hotend wiring harness with the hotend, so at present I don't have a spare

Yes, the DRV8825 drivers are noisier than the Duet. This is true. Not nearly as noisy as the router chewing through wood though. With my hearing protection on, I can sometimes hear the motors as they move. Without the hearing protection, no chance, the tool drowns it all out.

In terms of "realtime" I don't think that Marlin is either, as evidenced by the fact that the display shows the current position being somewhat ahead of the actual tool position. This is not a disadvantage to the Duet. There are some macros that I would like to be able to set up for positioning, tool changes and the like that Marlin is a little clunky with.

-

-

@SupraGuy

I started configuring with RAMPS board paired with v1Pi (Octoprint and CNCJS). Then I switched to duet within a day. I agree there was a short learning curve but an awesome community here at duet and with @jay_s_uk 's help I was able to get up and running in a day. The duet board is awesome. I really like it. -

@mtcl The community there is pretty good too. I fried a duet just before completing the MPCNC build though. Ran the hot end of my printer over the cable bundle and short circuited some stuff. Made switching to a Duet a little more difficult than it would otherwise have been.

I do believe that the Duet would make an excellent platform for the MPCNC. I already did have most of what I'd need to do planned, just not tested live. The macro coding, and particularly with conditionals could make some functions so much better, like tool changes with retries for positioning...

That all said, the simplicity of "download the pre-configured firmware" has some appeal. (And I'm saying that as a coder.)

Well, when I get my repaired board back, I might convert it still... But I've started design on the next 3D printer, so... Maybe not.