Inconsistent results with optical encoder wheel filament sensor

-

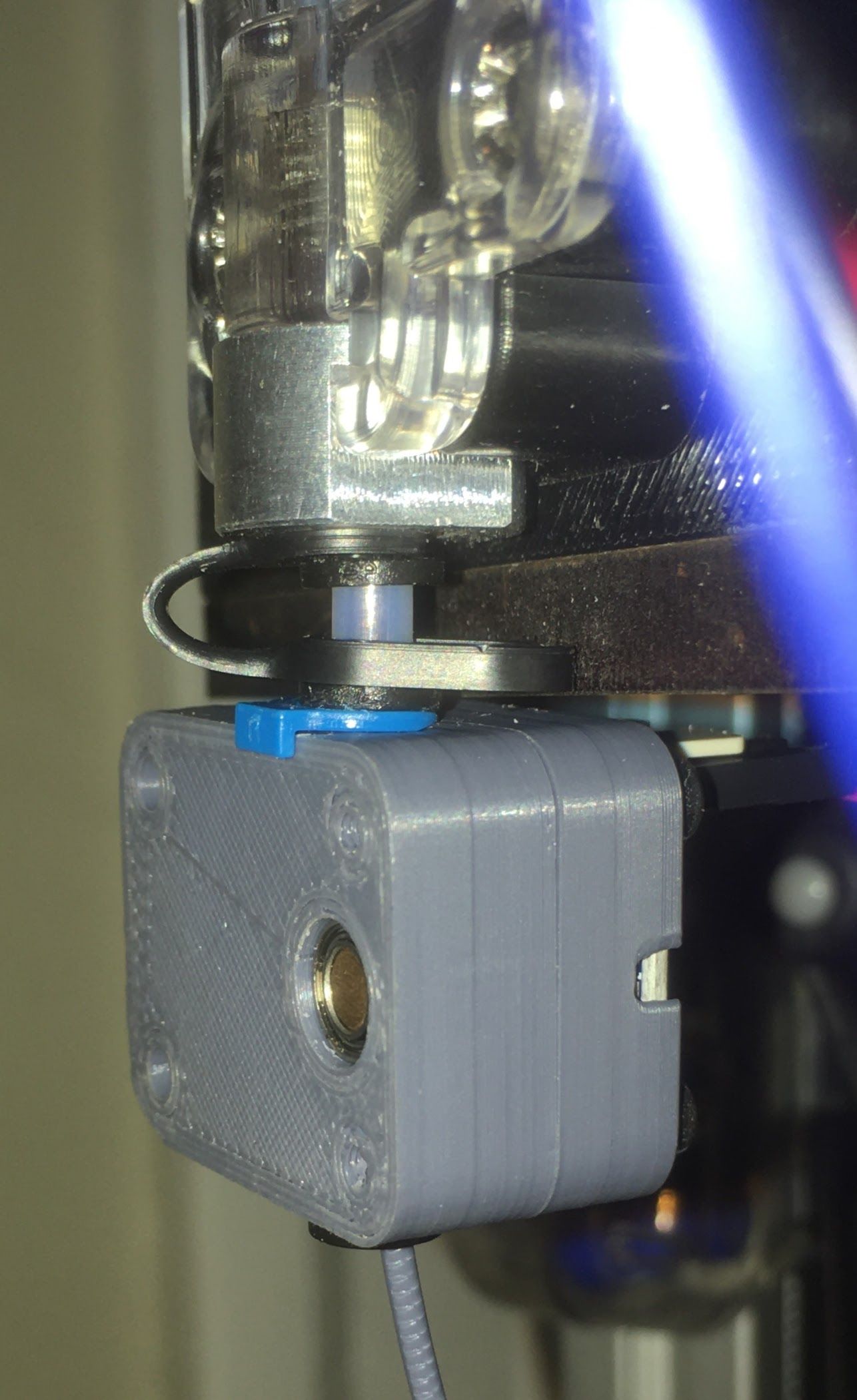

Your filament monitor travels inspired me to take the easy route and order the parts for a magnetic filament monitor from filastruder.

I printed out the case parts, did a tiny bit of scraping with a hobby knife and it's all running perfectly!

Unfortunately, I wasn't thinking and I mounted it to the bottom of the extruder because it's simple. But that means that when the extruder runs to the end of the filament and stops extruding there will be up to 3mm of extrusion missing on the print before the monitor says "No filament movement".

So I'm going to mount it above the extruder far enough so that the filament runs out at the monitor FIRST and there will be plenty to extruse for 3mm before the monitor finally says there's no filament movement.

Unfortunately, the EZStruder doesn't have a PTFE tube connector on its input-side do I'll have to hard-mount the sensor above the extruder. No big deal, but it's just something I'll have to do.

Anyway, $40 well spent in my opinion.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

Your filament monitor travels inspired me to take the easy route and order the parts for a magnetic filament monitor from filastruder.

I printed out the case parts, did a tiny bit of scraping with a hobby knife and it's all running perfectly!

OK, now you are just rubbing it in.

I'm curious how that filament monitor would perform mounted further ahead of the extruder. They seem to suggest against it. On the other hand, for "filament out" basic switch sensing, the position I have (on the printer frame -- about ~350mm from the extruder) works fine. It is where I've got the optical sensor installed.

Who knows. At the end of all this I might throw in the towel and follow course, assuming the magnetic sensor would be OK on the printer frame.

-

HEY! I still have my old "Filament out" microswitch before the extruder so I can wire that directly to the magnetic movement monitor and have BOTH!

Thanks for making me look at the documentation again!

You folks are great.

Filastruder installation instructions

After the extruder:

On systems that use a bowden tube it is also possible to mount the filament monitor after the extruder. In this case filament out will not be detected until the end of the filament is in the extruder. The second two pin header on the PCB is connected a separate filament sensing switch if you want to detect filament out before the extruder, but detect movement after the extruder. -

@JohnOCFII "assuming the magnetic sensor would be OK on the printer frame."

I can't see where you have your filament monitor mounted right now.

Assuming your bowden is all tight at both ends, I think it should be possible to mount the monitor back near your spool holder.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII "assuming the magnetic sensor would be OK on the printer frame."

I can't see where you have your filament monitor mounted right now.

Assuming your bowden is all tight at both ends, I think it should be possible to mount the monitor back near your spool holder.

Yes, it is back by the spool holder:

-

@JohnOCFII That should work just fine if you decide to go this way.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII That should work just fine if you decide to go this way.

If Tim @Filastruder has any extra bits, I might order one today with the current sale. The regular one is out of stock, but I understand that is just due to the case. My printers are precise enough that I'm sure I could get the case going.

My Digi-Key order arrived, but work has been too busy this week to open it up or to think about wiring yet.

-

@JohnOCFII The three case parts printed easily at 0.1mm layer height with PLA and printing slowly on my Rostock Max V3.2 with a 0.5 nozzle.

The only thing is the pin and guide are slightly too short on the Idler part so the bearing can drop off the filament as it moves "up" in the case.

I just installed it bearing-side in and it's fine.

If you're able to modify the .step file provided on their github repository, I would go 1mm thicker for these two polygons.

I can't figure out how to modify a .step using FreeCAD, but it's supposed to be possible. Maybe I need to spend some YouTube time this afternoon.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

Your filament monitor travels inspired me to take the easy route and order the parts for a magnetic filament monitor from filastruder.

I checked with FilaStruder, and apparently you got the last one.

-

Are these discontinued? I'd like to add this to my setup but it's never been back in stock, for months now.

-

@cdthomas9 They are trying to figure out how to get the cases made.

I don't know what the issue was.

-

@cdthomas9 said in Inconsistent results with optical encoder wheel filament sensor:

Are these discontinued? I'd like to add this to my setup but it's never been back in stock, for months now.

Yes, it is an issue with the cases. I think they switched technologies (SLS to injection molded?) and COVID has somewhat slowed the process, or lowered priority.

-

@JohnOCFII I sent you a chat message with a contact at Duet3d who might be able to help you with a magnetic filament monitor parts kit.

Let me know if you didn't get the message and how to send it to you.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII I sent you a chat message with a contact at Duet3d who might be able to help you with a magnetic filament monitor parts kit.

Let me know if you didn't get the message and how to send it to you.

Weird -- I get emails for message updates, but not "chat" updates -- so I hadn't seen that message.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

https://www.digikey.com/en/products/detail/texas-instruments/CD40106BE/376602

If you want help wiring it up, let me know.

I took the whole week off for Thanksgiving. Time to get back into this.

It looks like I connect pin 7 to ground, and pin 14 to 3.3V power.

It looks like most of the rest of the pins are paired. I'm not sure if it matters which pairs I use. Looks like I could connect from the optical sensor to Pin 1 (for input) and connect from Pin 2 (for output) to the Duet.

Would that be correct?

(This from the diagram on page 3) in the PDF below: https://www.ti.com/lit/ds/symlink/cd40106b.pdf?HQS=TI-null-null-digikeymode-df-pf-null-wwe&ts=1606236503315

-

@JohnOCFII That's all correct.

It doesn't matter which inverter you use. You just need to make sure to use the input of one inverter and the output of the same inverter of course.

I don't remember what your optical receiver circuit looks like, so you might need either a pull-up or a pull-down on the input to the Schmitt trigger inverter pin #1.

You can connect pin #2 directly to the Duet input pin.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

I don't remember what your optical receiver circuit looks like, so you might need either a pull-up or a pull-down on the input to the Schmitt trigger inverter pin #1.

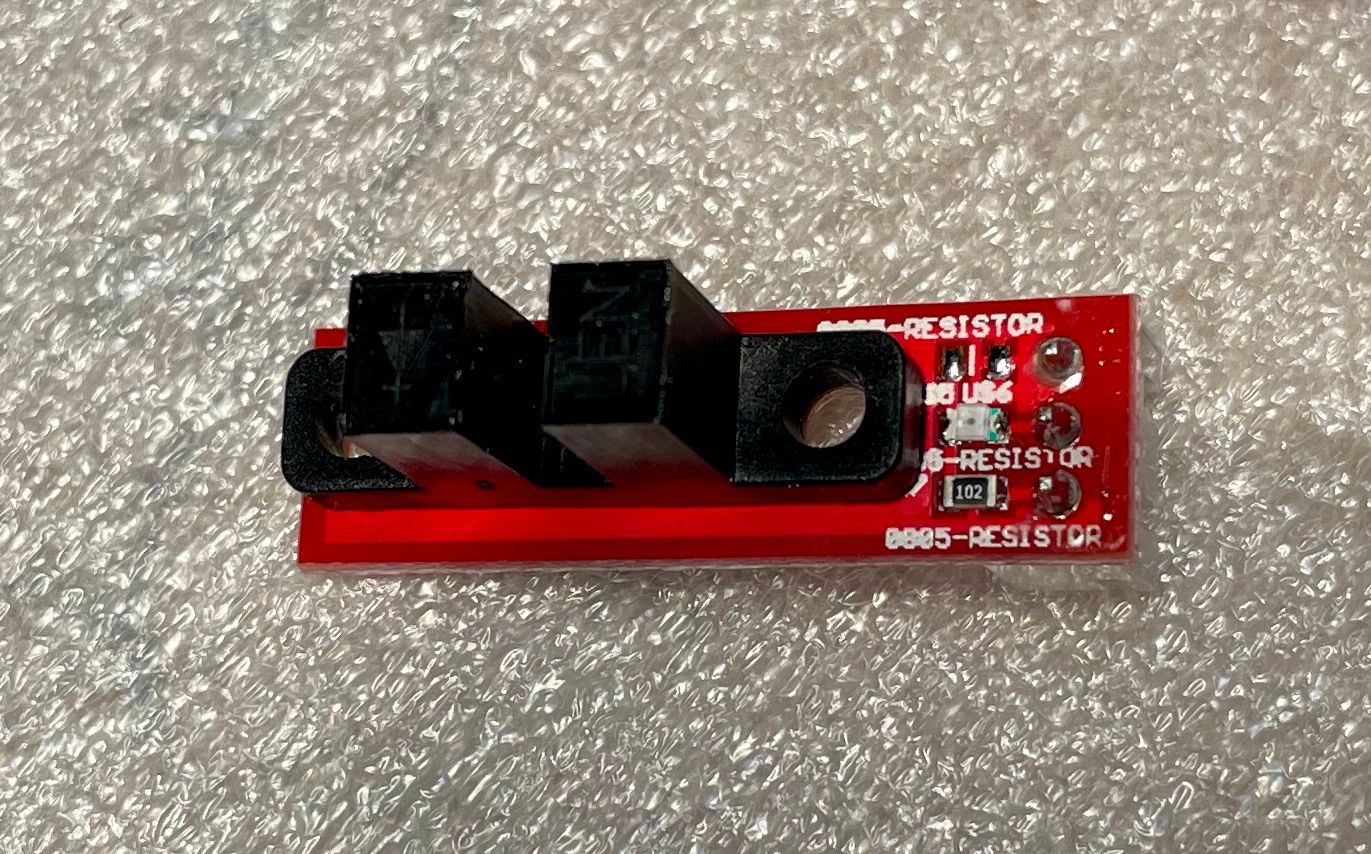

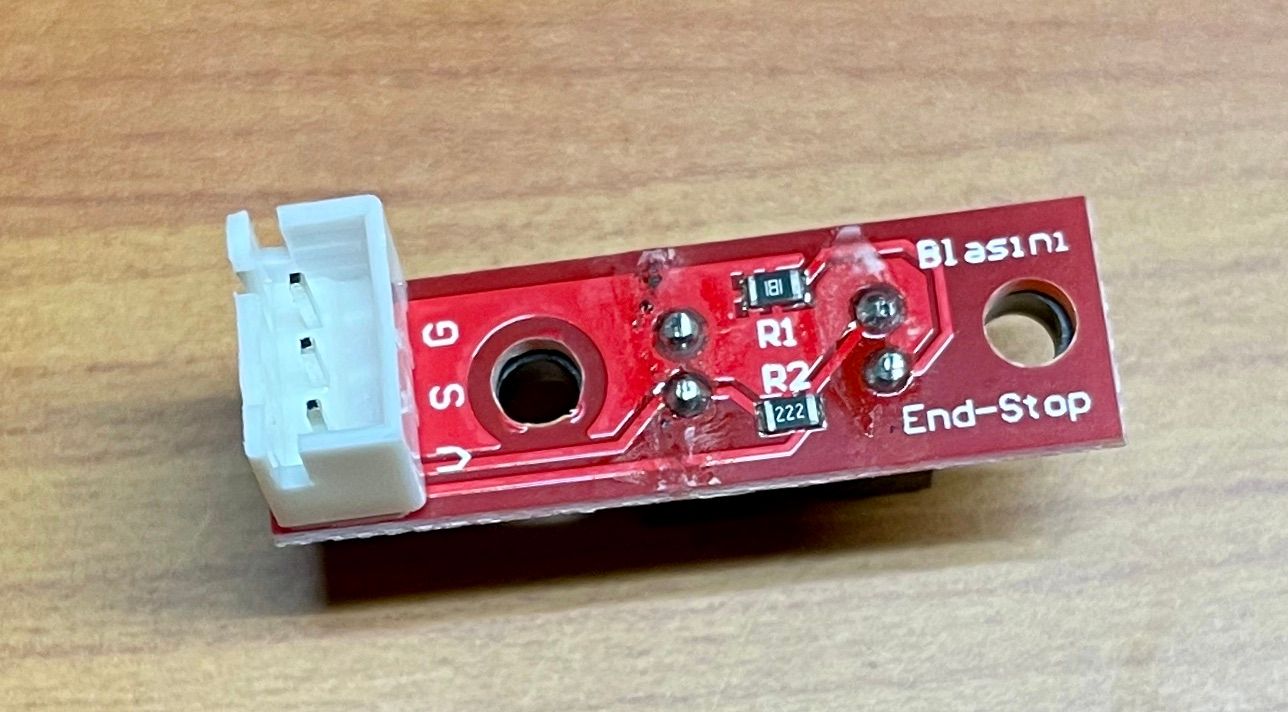

Here are two photos of the optical sensor. Not sure it is clear enough to indicate presence or absence of the pull-up or pull-down resistors.

-

@JohnOCFII

R1 is a 180 Ohm resistor in series with the emitter LED.

R2 is a 2,200 Ohm resistor to pull UP the receiver signal line.The resistor on the top is a 1,000 Ohm resistor in series with the LED on top. Is that a power-on LED?

So I would just hook it directly to the input of the Schmitt-inverter. No pull-resistors required on the input or the output of the inverter.

-

@alankilian said in Inconsistent results with optical encoder wheel filament sensor:

@JohnOCFII

R1 is a 180 Ohm resistor in series with the emitter LED.

R2 is a 2,200 Ohm resistor to pull UP the receiver signal line.The resistor on the top is a 1,000 Ohm resistor in series with the LED on top. Is that a power-on LED?

So I would just hook it directly to the input of the Schmitt-inverter. No pull-resistors required on the input or the output of the inverter.

The LED is not a power-on LED -- it lights up when the light beam is broken. Interestingly, there is a corresponding e1stop LED on the Duet board as well.

Thanks again on the advice. I'll try to wire this up tomorrow!

-

@JohnOCFII AH! I tool another look at a larger zoom level and I do see that the LED is connected between positive voltage and the output signal.