could Simplify 3D cause this anomaly?

-

Not Duet related.

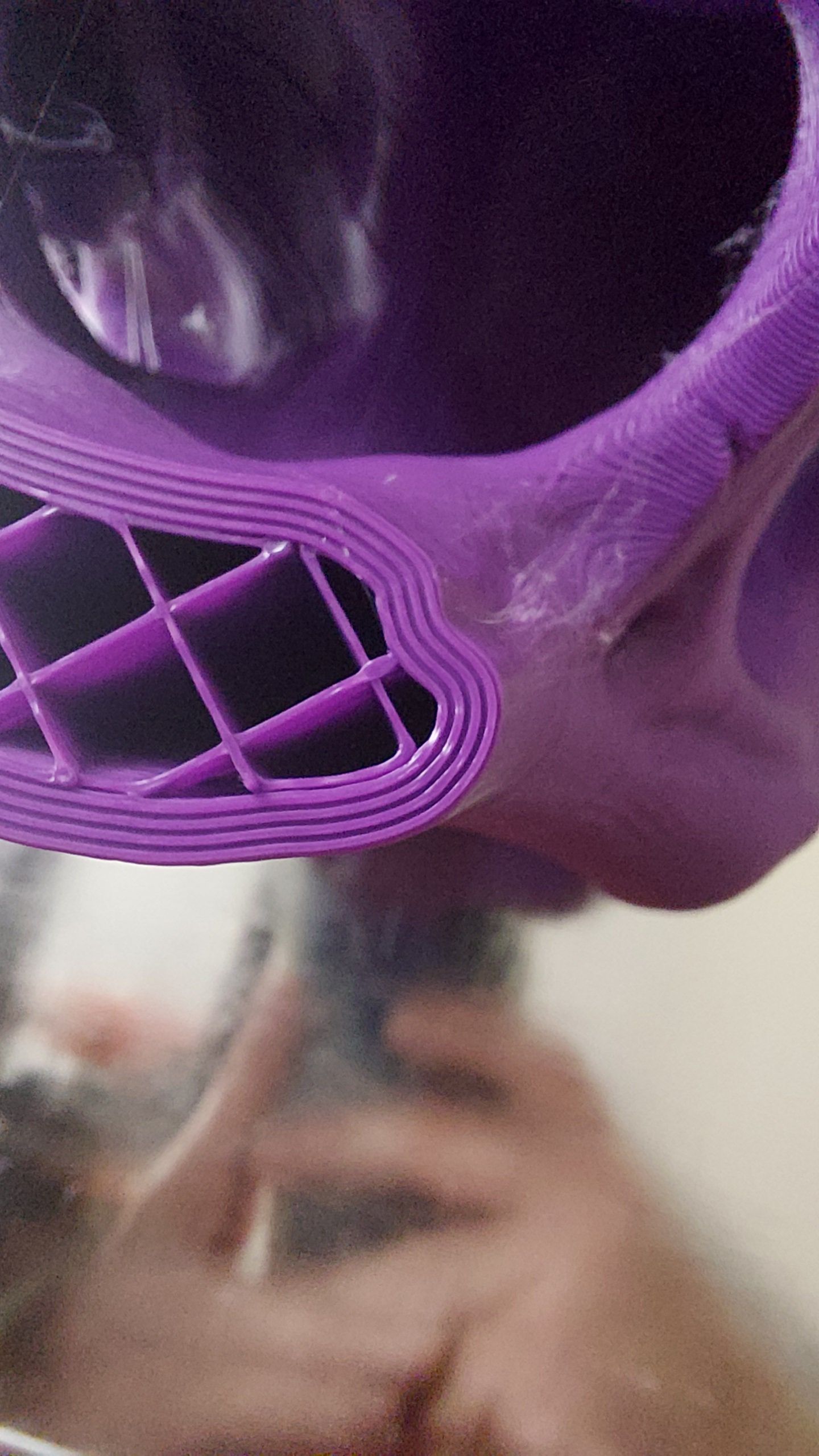

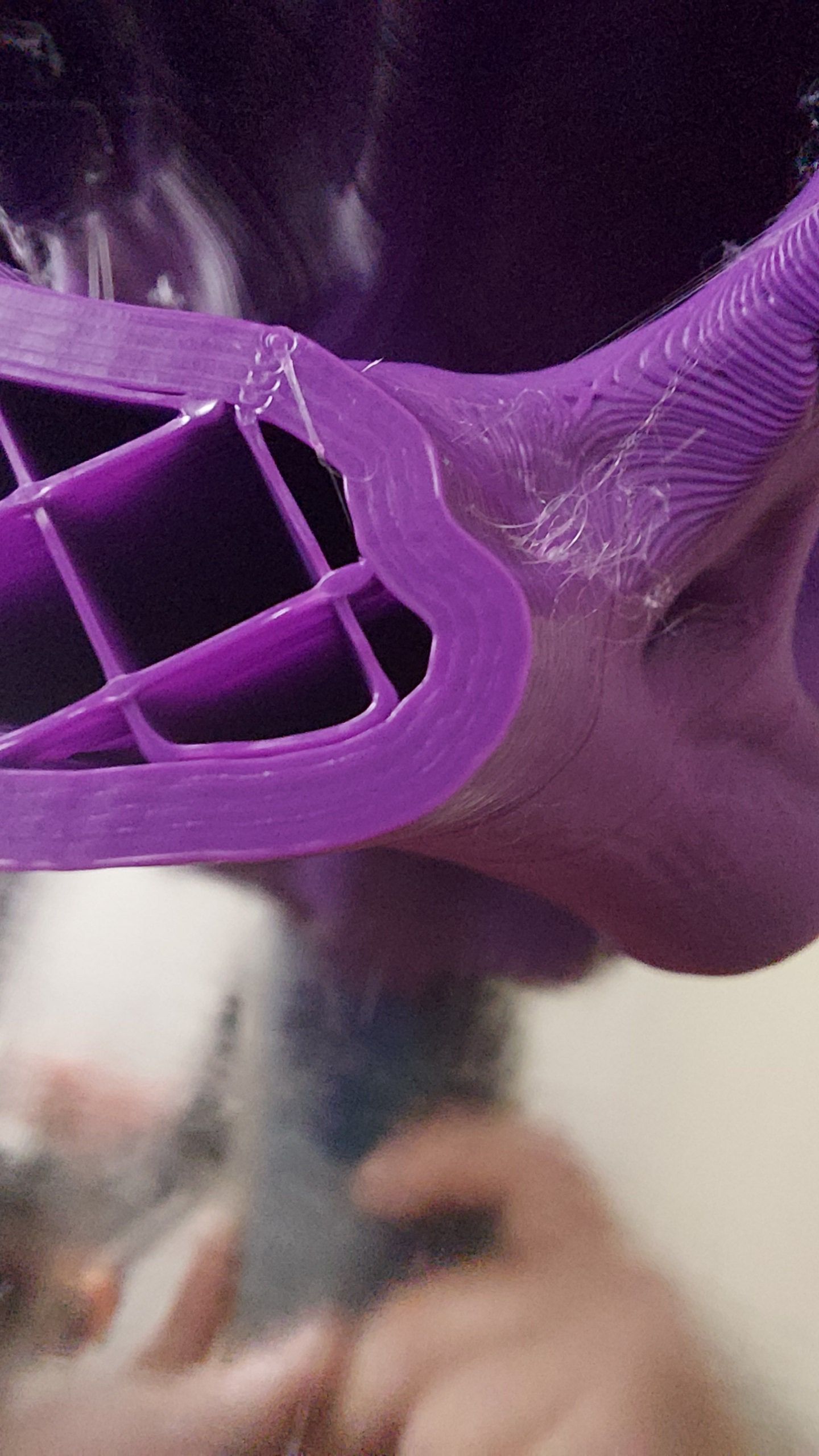

Noticing a problem with my prints and I am starting to think it is S3D.

Im getting layer lines and under extrusion. I've done the usual tests and troubleshooting, so belts, temp, cooling, bed, are all fine.

The reason why I think it is the slicer is because of how it is printing. When I follow the nozzle on its wall path, looking down at the top view of the print, I can distinctly see the side to side wall adhesion. One layer, it will be like glass and you can barely see the lines between the walls. The next layer, you can see gaps in the walls that I can see very easily. This is happening like binary code. 0 1 ...every one layer is clean, one other layer thinned.

Why would this happen and do you think it is S3D?

If the slicer can't do that, then maybe my machine is layering to high on every other layer. I'm a bit stumped on this and could use another set of eyes. Print is paused for now.

BTW, Duet Wifi board, running a modified Creality CR10S, 0.6nozzle, .16 layer height, 50 to 60 mms, running rep rap firmware. Ill post a picture shortly. But description describes it exactly.

-

Cleaning the nozzle while paused. Will try printing again.

No fix. Will change the nozzle if needed.

Still looking at S3D.

-

This sounds mechanical to me. Do the gaps between perimeters line up with an axis? It could be backlash I’d the layers are being printed clockwise then counter clockwise. Check for lose belts or lose rails.

-

-

@RyanP

just install another slicer and test -

@RyanP as @Veti said when you suspect slicer issues try another slicer. I preach that everyone should try all available free slicers every 6-12 months just to be informed what's availabled

Now the issue you mentioned (one layer this another layer that), check if you configured "combine layer", e.g.

- infill/combine infill every...

- support/combine support every...

Do you have anything in the change layer script?

AFAIK there's no way to tell s3d to do what you are experiencing "by mistake", you would have to vary the extrusion width trough layers trough layer change script or trough processes as from what I see you are experiencing this in perimeters... but you can easily test by quickly nistalling ideamaker, it looks lot like s3d and is way more powerful than s3d so you can easily see if it will happen with it too.

To me this looks like a problem with Z height, the "fatter lines" are actually thinner layers than the "thin lines" where you get higher layer height due to whatever reason (mechanical issue, microstepping fail, motor fail...)