Have our slicers been wrong this whole time?

-

just to be clear, I have no strong position on any of these, just throwing ideas and opinions out there... English is not really in my language (not even close) and I'm already told I tend to sound like I'm fighting or holding a hard position on something while in reality I just said what I think but I'm very much willing to change my stand confronted by more logical stand I did not think about myself or faced with facts that change my stand

-

@bot said in Have our slicers been wrong this whole time?:

accuracy when measuring

Measuring is a science in itself

You have to define what exactly you want to measure.

If we are talking about holes in 3d printing objects I tend to look at what's "sticking out farthest" and don't care much about other stuff as if "what's sticking out farthest" is wrong I need to drill the object (as I do in most cases) .... other use cases will require different measurement .. I doubt the'res "one solution for all use cases" here

-

@arhi said in Have our slicers been wrong this whole time?:

@theruttmeister said in Have our slicers been wrong this whole time?:

I'm very much familiar with jetting technology...

I'm just a user there, outside of my aria of interest

4 Axis FDM is able to deposit finely controlled, discrete volumes of polymer...

With more control than most jetting tech as it is able to vary the velocity of its deposition (Jetting typically cannot). In fact, the ability to deposit truly continuous beads of polymer is a huge advantage of FDM vs Jetting.I disagree but hey, we can't agree on everything :D.

Why I disagree

-

when you start extruding there is an unknown time delay before plastic start exiting. This time delay depends on many factors and is mostly ignored by the slicers. Effects of this problem are "hidden" by "prime nozzle" parameter, pressure advance...

-

when you stop extruding there is and unknown time delay before plastic stop extruding and to add to that plastic does not exit at same speed during this "stop" time. Effects of this problem are "hidden" by "retraction", pressure advance, coasting, wiping...

So IMHO we cannot deposit "finely controlled, discrete volumes of polymer", we deposit something "close to it" and then hide the effects of the error.

What makes you think inkjet doesn't have similar problems? You ever put a 2D print under a microscope and measured the size of each dot?

Besides, this is like complaining that bicycles don't protect you from the rain, but horses eat grass.

These two things are not in any way related.Or do you mean droplets?

No, not really, I mean, some way of having discrete deposition possibility. No clue how, if I had an idea I'd come out with it :). Looking at this weird view of the printer I mentioned

I'm familiar. And its dealing with room temperature materials, which is a totally different world.

maybe some rotating drum with holes "accepting" a known discrete volume of molten plastic sending it further down the path

...

...To replicate the control you want would require a valve in the nozzle. That would allow you to maintain constant pressure in the melt chamber and instantly stop extruding.

Crude versions were tested in very early reprap... They did not work well.

Turns out that a valve that can withstand a few thousand PSI at 200-300C is difficult and expensive, especially if you want it to be small.

Retracting the filament is much easier and produces satisfactory results.I don't see much of a market for a $5000 printhead that produces slightly better prints.

-

-

@arhi said in Have our slicers been wrong this whole time?:

@bot said in Have our slicers been wrong this whole time?:

accuracy when measuring

Measuring is a science in itself

What he said.

-

@theruttmeister said in Have our slicers been wrong this whole time?:

To replicate the control you want would require a valve in the nozzle. That would allow you to maintain constant pressure in the melt chamber and instantly stop extruding.

Crude versions were tested in very early reprap... They did not work well.I know about those "crute versions", I made one myself back in the day... didn't work well, but with new technologies and materials... who knows.. the piano wire + solenoid shown to be ^%#$^# but maybe some new piezo controled nozzle stuff ... they supposedly made a CPAP device that uses a pump made out of lot of small piezo elements, who's to say something like that can't be used for plastic

I don't see much of a market for a $5000 printhead that produces slightly better prints.

It's a huge question how "slightly" better it would be. That precise head could hit the SLS accuracy easily if paird with good mechanics, the problem I think is that with so high price you just go SLS way, you get strong parts, higher precision, way less issues with overhang and everything faster

-

Inkjet works because its not under pressure, the ink is of very low viscosity. The piezo squeezes the ink out of a long thin tube. Capillary effect and all that. All at room temp (or less than 100C for wax).

FDM is using high pressure (hundreds to thousands of PSI) due to the viscosity of the materials, through a much bigger nozzle. At temps from 200 to 450C. They are fundamentally different processes.

A pump for moving air using piezo elements is interesting, but not in any way applicable.

The challenge is that making a really tiny valve that is durable and can maintain a seal is going to require lots of engineering.

A brass nozzle and steel wire/needle valve, is going to have worn out brass really fast, for example.A tungsten carbide nozzle, with a internal tungsten carbide needle/piston... that would get you a good and durable seal at one end. Now you just need to seal the other end... and figure out how you are going to get the filament into the melt chamber. Oh, and how to actuate that piston.

Of course you could also try and build something that is spring-loaded, but that's a whole other challenge.

And I don't think it is a huge question of how much better it will be. Its not going to change the fundamentals of how FDM works. Its just going to make cleaner starts and stops... the returns are really marginal.

And you go to Multi-jet Fusion long before SLS, its much cheaper.

And SLS isn't blanket better, it still has lots of design constraints, plus much more problematic overheads.

Part shrinkage, part warping, minimum wall thickness, material choice (and mono-material only), surface finish, object density. These are all very different from FDM.And SLS is actually often slower when you actually allow for complete cycle time. Given that you need to pre-heat all your powder, then cool the build chamber very slowly.

-

@theruttmeister said in Have our slicers been wrong this whole time?:

Inkjet works ...

I just mentioned what does discrete deposit.. will this be or not possible for FDM, I'm pretty sure those technologies will not but just like we moved from needles to jets who knows where will we move "tomorrow" from existing solutions for FDM. maybe nowhere, maybe... with enough ppl working on solving the problem lot of things are possible

And I don't think it is a huge question of how much better it will be. Its not going to change the fundamentals of how FDM works. Its just going to make cleaner starts and stops... the returns are really marginal.

This is where we disagree, I believe that "how much will it change" really depends on the solution.

And SLS is actually often slower when you actually allow for complete cycle time. Given that you need to pre-heat all your powder, then cool the build chamber very slowly.

depends, if you do full chamber at once, which is rather easy with SLS, speed / volume is much higher than FDM .. if you do small parts, yes, then fdm is faster

-

The discussion seems to have wandered a bit here. I don’t know why we think we have to do anything special to get resolution or precision or discrete extrusion commands. We already have it.

IMO, the FDM process can be scaled up or down however much someone wants — there is nothing about the fdm process that fundamentally precludes high precision. We can have tiny nozzles and use a stepper to push it out and get great results. If I had a nozzle that was 0.08 mm orifice diameter, and an extruder that had about 10,000 steps/mm at 16x ms, I wager that I could print 0.08 mm extrusion widths at 20 micron layer height.

The problem becomes making the nozzle at this point. And also achieving the resolution on the E axis.

-

@bot said in Have our slicers been wrong this whole time?:

The discussion seems to have wandered a bit here

That tends to happen even with much more focused discussion

If I had a nozzle that was 0.08 mm orifice diameter, and an extruder that had about 10,000 steps/mm at 16x ms, I wager that I could print 0.08 mm extrusion widths at 20 micron layer height.

I would take you on that as with ABS/PLA/PP available today pushing plastic trough .1mm orifice is not working. It clogs non-stop from particulate from the filament itself (filament is cleaned and even goes trough static electricity removal chamber). I doubt you can have ABS/PLA/PP that's clean enough to run consistently trough .1mm. It has bin tried by me and few others many times before. .2mm is kinda best you can do with plastic that's available, that's why noone really pushes smaller nozzles than .2mm, and even .2mm is too much hassle, .25 is the smalles I go myself these days.

-

@bot said

IMO, the FDM process can be scaled up or down however much someone wants

There are major caveats to that... (gigantic ones).

— there is nothing about the fdm process that fundamentally precludes high precision. We can have tiny nozzles and use a stepper to push it out and get great results. If I had a nozzle that was 0.08 mm orifice diameter, and an extruder that had about 10,000 steps/mm at 16x ms, I wager that I could print 0.08 mm extrusion widths at 20 micron layer height.

The problem becomes making the nozzle at this point. And also achieving the resolution on the E axis.

Making the nozzle isn't the problem... I can get you a ceramic nozzle with a 0.07mm orifice, probably even one from tungsten. Might be expensive. MOQ might suck too.

The problem is that required extrusion force increases exponentially as the orifice size decreases. There is a point where you can't actually generate enough pressure with the filament. Or even that the thermal expansion of the filament in the melt chamber is actually faster than the deposition rate.

There is also a point when you get small enough the flow boundary on either side of the nozzle meets, then you just can't push material at all... Or maybe you get small enough that your flow rate of material through the nozzle becomes supersonic, then it just stops.Also you are not talking about high precision, you are talking about really high resolution (which by necessity requires high precision, but is not the same thing)...

You are going to also want to switch to ball-screws if you are not using them already. Probably harmonic gearbox for the extruder (the amount of lash and resulting delay on retraction wants to be minimised), that would get you to the right region for E resolution.Don't get me wrong, I'd love to see just how far FDM can be pushed to produce really high resolution prints... I'm just not convinced there's a market for SLA resolution but with print times measured in days.

I mean, there is a market. But its for about 10 machines. And it needs to be printing in nonsense materials. -

At what point do you think this pursuit of resolution or precision or accuracy or whatever term you want to use, is impossible? I'm using, like I said before, a 0.15 mm nozzle with 0.04 mm layer heights. How much lower do you want to go exactly? I'm pretty sure I could match polyjet resolution with the right system. The actual problem/limitation is print speed. FDM is simply inherently slower than most other processes. It's not inherently less-capable of producing higly detailed, high-resolution, accurate prints with great precision.

-

@bot said in Have our slicers been wrong this whole time?:

At what point do you think this pursuit of resolution or precision or accuracy or whatever term you want to use, is impossible? I'm using, like I said before, a 0.15 mm nozzle with 0.04 mm layer heights. How much lower do you want to go exactly?

Me? I'm happy with 0.4mm nozzle, 0.2mm layers. That means I can get parts in hours, not days. I have work I need to get done.

Impossible? Sounds like @arhi thinks 0.1mm nozzles are functionally impossible. But who knows.

I'm pretty sure I could match polyjet resolution with the right system. The actual problem/limitation is print speed. FDM is simply inherently slower than most other processes. It's not inherently less-capable of producing higly detailed, high-resolution, accurate prints with great precision.

It is inherently less capable. The rheology of molten polymers just is more limiting than that of low viscosity ink through an inkjet.

That doesn't mean it can't produce high resolution. Just that the trade-offs to get there make it impractical for most people.If you want to go chasing 15 micron layers, with 43 micron features... good luck, I'm sure it will be fun.

If I was building a high rez machine for printing nonsense polymers, I'd probably be happy with 0.1mm layers and 0.25mm features. I'm down with printing tiny expensive things that cost far too much money, but I want it to take less than a week.

-

I'd appreciate it if we could return to the topic at hand, if all you want to do is badmouth other people's ideas.

-

@theruttmeister said in Have our slicers been wrong this whole time?:

Sounds like @arhi thinks 0.1mm nozzles are functionally impossible. But who knows.

They are functionally impossible if you ask me! They clog non stop, you have to use 40:1 gearing in order to push filament trough and you need to print very hot ... I never managed to print a benchy with .1mm nozzle (smallest nozzle I managed to finish a print is 0.16mm and it's a World easier than 0.10mm) ... and this was with .1mm nozzle with exit channel shorter than .1mm!!

@bot sorry for the off-topic, I'll try to stay on the topic

-

I suppose I can accept 0.1 mm nozzle orifice as a reasonable lower bound for potential good results. Much like theruttmeister, I have no desire to go much lower than I am already. I do prefer to have the capability to do very high resolution prints, as well as low resolution prints, in order to expand the range of objects I can print. Being capable of printing at the widths and heights I am doesn't limit my ability to print 0.3 mm thick layers out of a 0.4 mm nozzle at 100 mm/s.

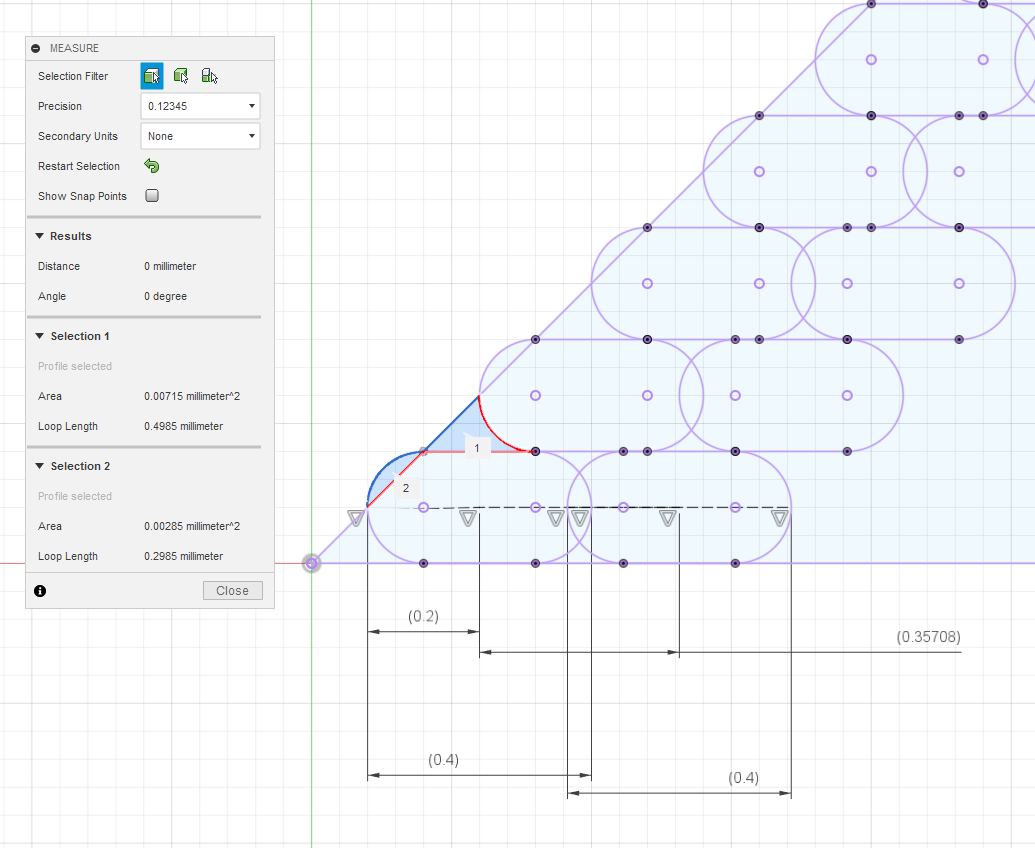

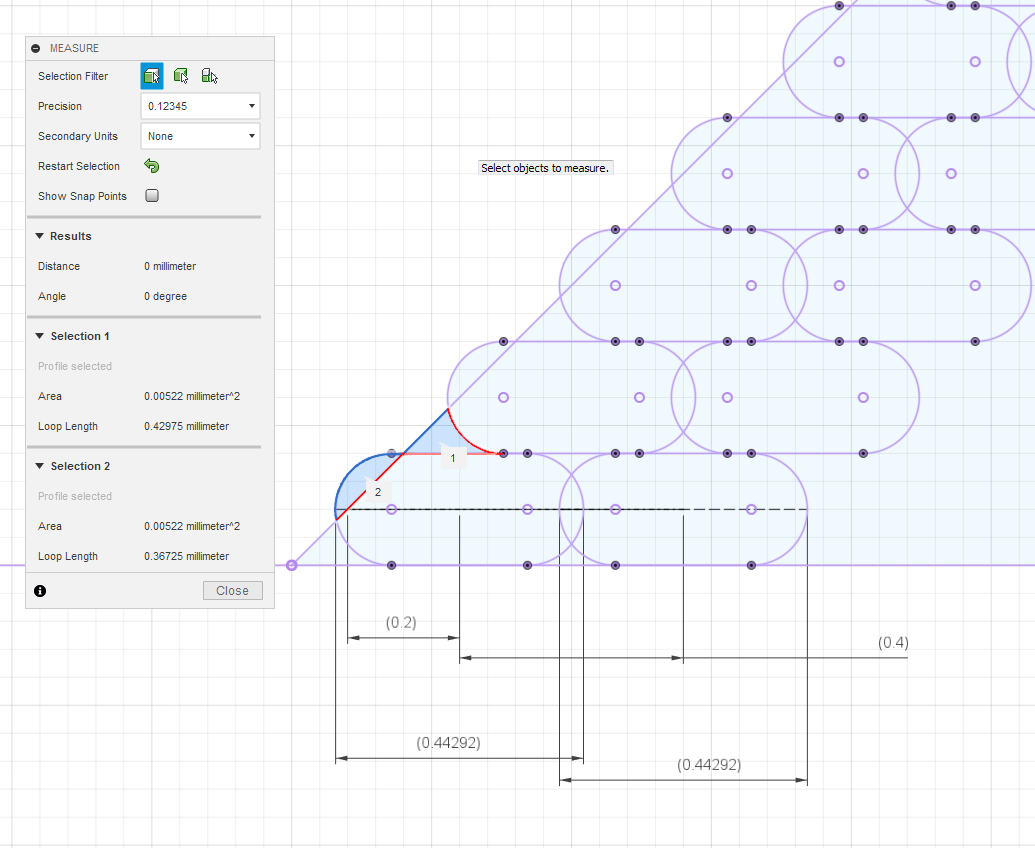

BTW, here is why the Slic3r flow math is less accurate. It puts a bias towards parts being too small, when you consider the volume. The following pictures show exactly theoretically perfect extrusions as dictated by the Slic3r model. Variation plus or minus due to filament diameter fluctuation is inevitable. Mathematically, Slic3r produces undersized parts with more probability.

0.4 mm requested extrusion width, 0.2 mm layer height.

Like I've said before: don't sand your models, and make sure they don't see much abrasion in use! You must not be producing functional parts if you don't care about the surface being made up of mostly void space.

-

But anyway, let's get back to the topic of discussion:

-

@bot well, assuming you can ideally control what comes out of the nozzle that start you are talking about is fixed with nozzle prime value, isn't it ?

-

@arhi Sure. It is fixed with "extra length on unretract" or whatever term slicers use. The problem with that method is that this prime amount is not subtracted from the requested extrusion of the line it is part of. This is why the segment needs to be split off, so we can meter the filament properly.

Instead of just priming an extra 0.25 mm or whatever, it's priming the exact amount required to print the extrusion underneath the nozzle, then from there it continues on with the amount already extruded accounted for. When you do extra prime, the extra amount is not accounted for.

-

Ahem.

@theruttmeister said in Have our slicers been wrong this whole time?:

Its easy to test your theory.

In Cura (where I can remember the setting), try playing with the 'Retraction Extra Prime Amount'. Which I'm fairly sure will produce an effect similar to what you want to get.

I think that you are going to be in the system noise of it all though. You are talking... [does some calculations]

A full 'spot' with a volume of 0.025mm3.

That's ~10 microns of filament, at 1.75mm.

Or half that, if you are just trying to start a line.Admittedly I didn't compensate for wall curvature, so the spot would be a hair larger than desired. And I was assuming 0.4mm extrusion width, 0.2mm layer height.

The math isn't that complex. Why not test it and see if you can detect any improvement? If you are correct you will see either no hole or a bump.

-

Yeah I'm planning on doing that when I get finished with a ton of other things on my to-do list. I'm trying to encourage discussion to see if the idea can be refined further. It's dealing with such theoretical elements, that the real-world tests aren't that important. What's important are the dynamics of the way the firmware will work with this, and how the slicers might implement this feature and how other methods or approaches might be better.