3DAVII

-

Hi all,

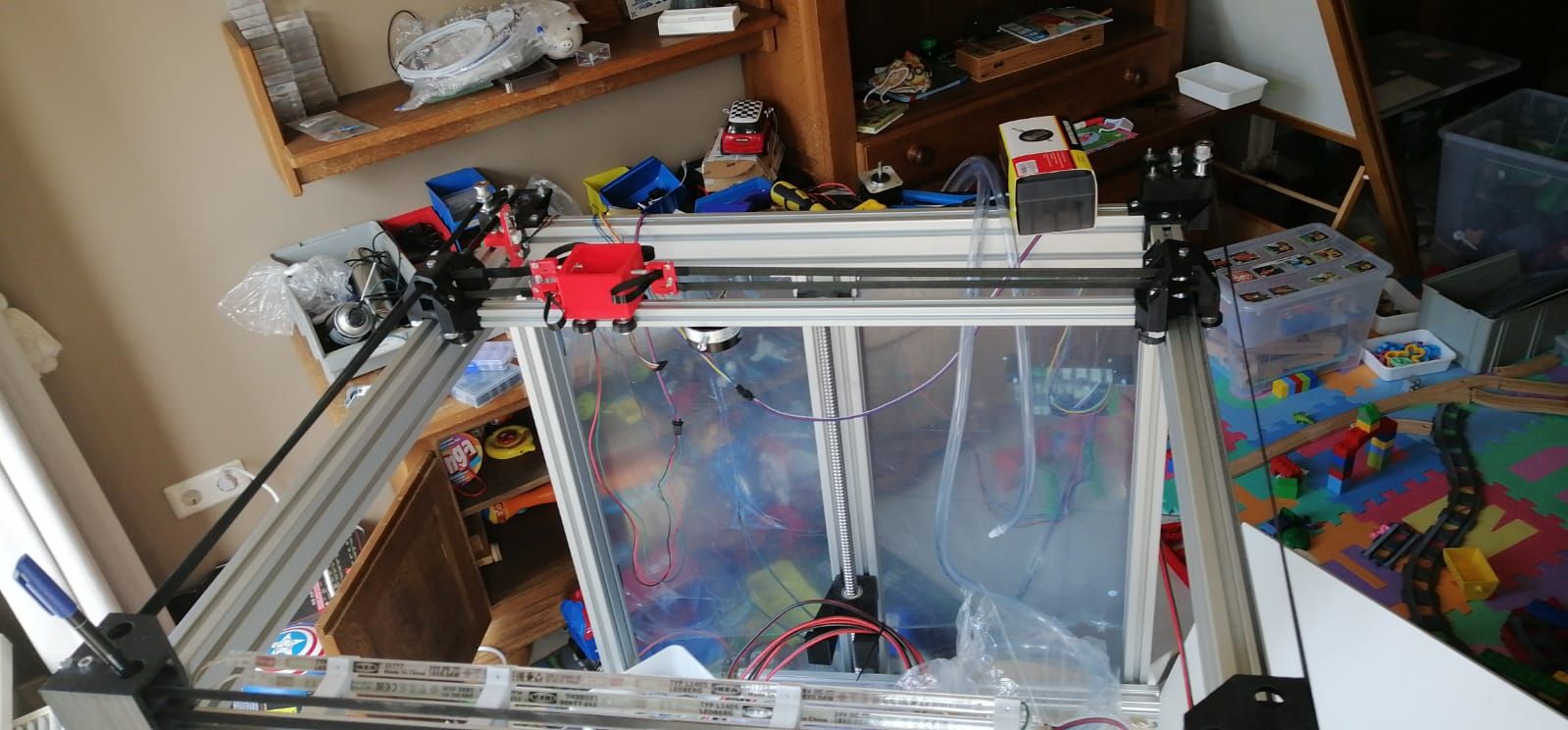

since I'd like to share my new printer design. It is my second printer design, I'm using a DuetWifi to drive the printer.

The printer is being designed for my dad who has ALS. So my mom needs to be able to operate the physical aspects. This means as little as possible calibration and such. The first printer I've designed for him works well however there are a number of things I would to improve upon with this design:

- Repeatability (This is ok on the old printer but could be mich better)

- Size (My dad would like to print larger things)

- Auto bed calibration (Even with bed leveling my mom is sometimes a bit to rough with the bed and it gets out of alignment)

- The print operation needs to be at a comfortable viewing heigt from wheel chair

So why not buy a ready build printer you say: Well cost and hobby! My dad also loves engineering so it's great working om it together.

Details:

- Total dimensions: +/- 700x700x1100(height)

- Max print dimensions: 500x500x600(height), Initial design might be 400x400x600 due to me not being able to find a glass plate of 500x500 (without having it custom made and being very expensive)

- Frame is made of 3030 and 3060 profiles which provides nice rigidity

- CoreXY (This works well now

), Currently using derlin wheels however I have ordered 3 linear rails which should be much better. (Driven by 2 NEME23s)

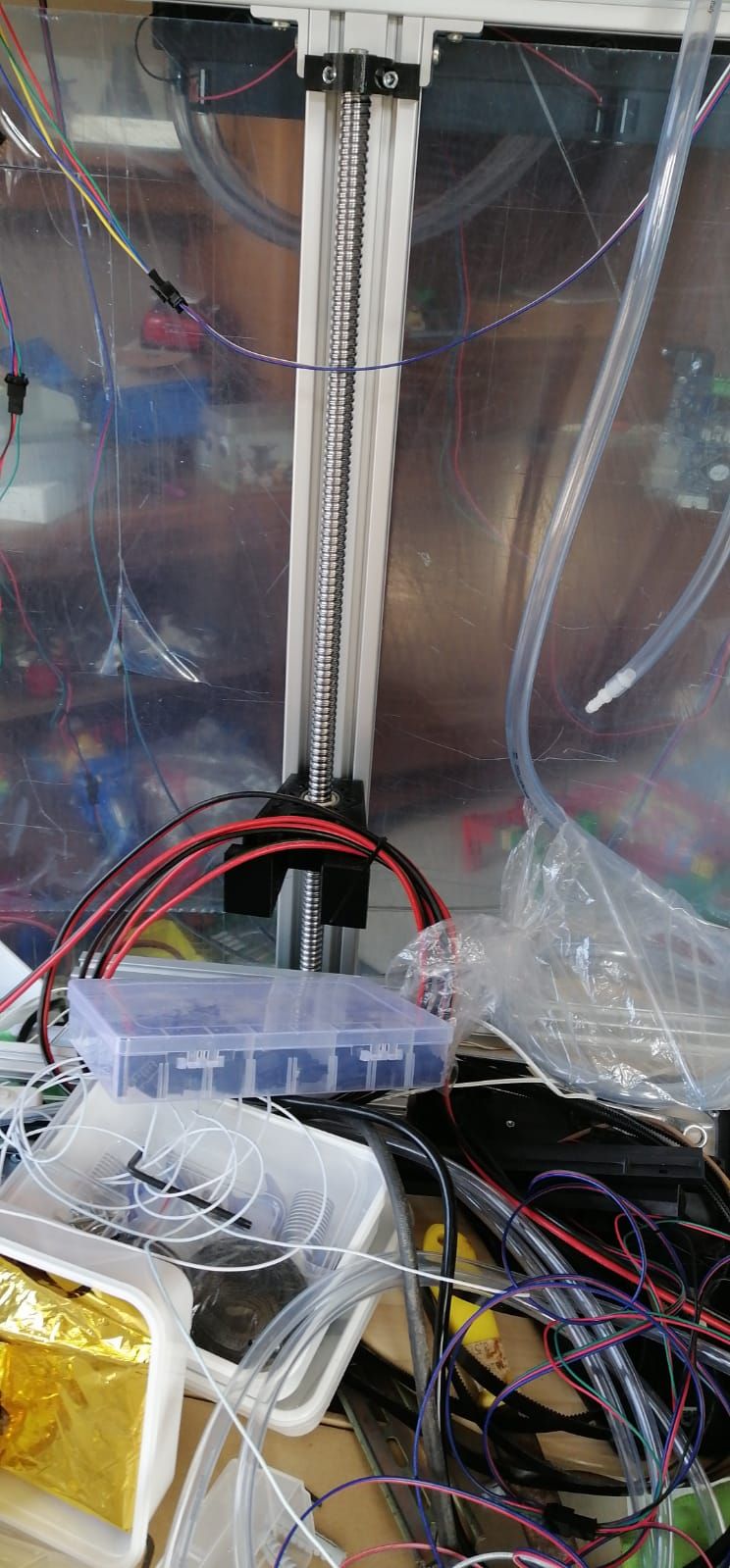

), Currently using derlin wheels however I have ordered 3 linear rails which should be much better. (Driven by 2 NEME23s) - 3 independently driven motors for the Z platform (Driven by 3 NEMA17s (0.9 degree), Each motor will drive a SFU1605 ballscrew of 700mm (about 650mm usable length).

- Bed sensing: Either BLTouch (initail idea) or touch sensor using piezo

- 1600W 230V bed heater switched by a SSRS

- (Optional/future) Exchangeable tool carriages

--> Tool carraige 1: A single E3D volcano

--> Tool carraige 2: A quad E3D kraken with volcanos - Easily accessible bottom compartment with spool holder and filament guides so changing colour will be less of a hassle

- Integrated UPS which can run the printer for at least 1 hour

A number of images (work in progress do not mind the mess and yes the missus is very patient!

The XY axes work however in one of the redesigns of the Y carriages I kinda forgot about the clearance for the returning belts... So near the motors there are temporary guides. Also the XY will be replaced by linear guides once they arrive.

I'll post movies later since the site does not let me upload them.

-

Looks great. In particular, the geometry and belt alignment of the CoreXY look correct (and some commercially shipping printers don't get this quite right!).

Nice job and quite nifty that you get to enjoy this with your dad.

-

@Danal Thnx. I was surprised how many designs do not have the CoreXY belts exactly parallel to the axes and do not use right angles (except for the back). To be fair my test carriage which was hastily designed and printed does not allign well I've figured out.

Still even though I put a lot of time into the design I'm still running into things that do not work as well as expected. Or not at all

Still gives my mom time to get used to the fact she'll be having a 700x700x1100 3D printer in her living room

Still gives my mom time to get used to the fact she'll be having a 700x700x1100 3D printer in her living room

-

@Nemesis1782 said in 3DAVII:

Still gives my mom time to get used to the fact she'll be having a 700x700x1100 3D printer in her living room

mom

- Informal noun used for every day saints and super heroes.Printer looks good though!