New Build! Want input!!!

-

Okay so I have a few successful functional prints that were accurate enough to use to continue to upgrade and tweak my Kossel Mini, things that do not require accuracy such as screen and paneldue enclosure, duet wifi enclosure (thank you dc42) which I also want to redesign to include fan mounts for the duet and potential driver cooling I'll share it when I'm done, a spool holder, better endstop holders, Raspberry Pi 3 case with a pi logo in it (nerdy but awesome), etc. My parents saw how nice the prints looked that were done with my 0.25 nozzle which I must say looked pretty darn good for a few hundred dollar machine.

My parents were intrigued and asked how long it took me to design all the stuff I've printed and I unintentionally laughed. I showed them sites like thingiverse, grabcad, and TurboSquid, for those of you that haven't heard of TurboSquid, it is thingiverse but for professionals and professional and accurate CAD models/assemblies. Check it out.

Even though something may cost lets say $200 to purchase a file, if I owned a CNC Milling machine, a CNC router, CNC lathe and maybe a few different styles of Precision Additive Manufacturing Machines, hypothetically, I could make some pretty awesome stuff if I was bad at designing parts, they would be accurate. If I was Semi-Competent, I might make some money. If I was good, I might start my own business. My parents are, more or less, on board, which means I will have their financial support. Telling an engineering student that there really isn't a budget for the next project, was a bit of a mistake on their part, one that I plan to take advantage if the cost benefit analysis goes over the way I want it to.

Moral of the story, I have a rather large budget and I want to Build and create my own Precision AM machine for functional parts to donate to my local FabLab so anyone there can use it as well as myself. I will also have the support of the Faulhaber family as long as my cost benefit analysis is done to professional standards. The new Stratasys machines can consistently produce parts accurate to 20-85 µm for features below 50 mm; up to 200 µm for full-size models. This is with the adoption of inkjet style extruders that can achieve 600 dpi X and Y and 1600 dpi on the Z. These inexpensive 3d printers are useful for everyday needs and can come even closer when parts when engineered in conjunction with precision cnc machining.

It is my belief that these machines are capable of much more and do not have to still be several hundred thousand dollars, which I understand the engineering involved is a large part of it, Faulhaber Motors are incredibly precise and incredibly efficient. I believe LinuxCNC could also do what I want, I'd rather not have to go that route. I am going to have to most likely add in some functions I need or want which may put me in a position to have to create a few custom circuit boards if I want to take full advantage of the motors with the encoders they use, which would be open designs of course. I have access to several electrical, mechanical, hardware and software engineers. I reached out to a few applications engineers at Faulhaber to go over some of the specifics of the motors and wiring to get the most performance and life out of their products as well as fish for an offer to be donated a few motors that would make this project a bit easier.

I am going to further develop this: http://cfg.mit.edu/content/multifab-machine-vision-assisted-platform-multi-material-3d-printing

In order to prototype this quickly and have it be not so expensive to prototype when I inevitably make mistakes, I am choosing to build a 3d printer prior to doing this. I want to use high precision ball screws, and the most precise stepper motors I can get my hands on and all of the parts will be CNC milled on a VF2 Haas 3 axis mill (with a rotary 4th).

I will be designing an enclosure similar to a convection oven that Stratasys uPrint Se uses at my local FabLab. I will be using extruded aluminum 30mm, 40mm or similar that my lab has in a corner collecting dust. I will be using linear guide rails and a ballscrew on every axis of motion, I am thinking of geared Nema 23 running 24V.

I would like input on how to build the highest precision reprap I could.

I will mainly be modernizing this: http://www.thingiverse.com/thing:59196

except with two Z motors and 2 ball screws having them on the sides rather than the back. I plan on simply just using e3d for a 2 or 4 nozzle 3d printer that could do some proper engineering materials since I already have a few hardened nozzles already. I will be documenting the entire build and have a dedicated server hidden below that will hopefully allow me to send a file through remote desktop to be sliced and sent to the printer from wherever and adding several cameras and sensors to increase the awareness of it.

What should I add or encorporate into my designs??

If money, or engineering time were no obstacle what would you add/do?

If money, or engineering time were no obstacle what would you add/do? -

Are you on reprap forum? If not sign up and seek out the_digital_dentist http://forums.reprap.org/profile.php?1,15485 read all his posts (or some of them) he is concerned only with quality and precision, and cares nothing for speed or value for money. It sounds like he will be right up your street. In fact if you've money to burn why not employ him to make you a printer, it will meet your requirements. Tell him I sent you and that I'd like 5% commission (I'm not a greedy man).

I'm quite serious, even if I might be being slightly sarcastic in the presentation.

Personally if I had plenty of money to spend I'd get a turnkey printer ie. a Stratasys or similar. The engineering challenge of building an accurate printer is not all about spending lots of money, but being precise when building the machine and making no compromises to save time, hassle or eventually money. My delta was built with a fairly no compromise attitude https://www.google.co.uk/url?sa=t&source=web&rct=j&url=http://forums.reprap.org/read.php%3F178,702599&ved=0ahUKEwj58e3Br9HSAhUMIMAKHZWSDcEQFggaMAA&usg=AFQjCNEC73P3fysSMdNar24gLlyn-ru3Zw&sig2=TFvV1kVtZAnXYsNcYdLLbw I could have spent more on the rails, I used the Chinese ones, but everything else was premium. About £1000 total. I'm very pleased with it, when I enclose it it will open up even more potential.

-

If precision is king, be prepared to throw away much of what you commonly see in 3D printers. Many are designed with a vastly different set of goals - Price, ease of manufacture, ease of assembly, speed of assembly, ability to print parts.

Your aim should be to use linear guides on all axes and not have any cantilevers in your design. (As you identified with your Z axis, but the same applies to the X axis where the hotend is often cantilevered - A pair of horizontal rails is better than vertical rails for this)

Having ballscrews on all axes would massively increase weight, which means you might need to consider larger motors. For the X and Y axes, I'd suggest using a relatively low pitch ball screw (2-4mm pitch) and also consider a stepper driver with mid-band resonance compensation so that you can still maintain decent travel speeds. (http://www.geckodrive.com/featured-products/g214-55.html)

Rigidity is king here, consider using a welded steel box-section frame with the tubes filled with resin and the mating surfaces milled flat. 40mm square tubes would probably be a good start.

You mention that budget was not a concern, but I'd still suggest that you set yourself a rough budget - It will help you while designing and it will help others gauge exactly what they can and cannot suggest.

-

Multifab has a problem, several in fact. I agree with you that we should have an inkjet printer for the hobbyist that isn't priced beyond the realm of reason. I've been working from the Multifab specs for a little over two years now. Precision is not the problem.

-

Multifab has a problem, several in fact. I agree with you that we should have an inkjet printer for the hobbyist that isn't priced beyond the realm of reason. I've been working from the Multifab specs for a little over two years now. Precision is not the problem.

I would very much like to know more about this, I was under the impression that Stratasys's Polyjet system was nearly identical to the Multifab project with the exception of using machine vision to allow the machine to see and learn. DC42's IR Probe gives my Kossel Mini more awareness (to keep it simple) and I expected the addition of a vision system to be a game changer. I imagine the biggest problem would either be hearing s**t from one of the big companies, or the integration and development of the AI agent(s). I would expect the open-loop nature of steppers would be a conflict which is why I planned to use servos. I planned on trying to hack an inkjet to try to work, the viscosity of the thermoplastic concerned me. I was going to take a shortcut and copy/modify Stratasys's Liquifier pump first as I really would not have to change that much, my first thought was a high temp peristaltic pump.

Precison is MY current problem, My Kossel Mini works, however, I cannot really create too many function parts to my standards…which may be a tad ambitious.

What are are a few of the biggest problems that are preventing, or slowing, the development? I recognized a few flaws in the technical papers and saw a few areas I would have chosen to solve a problem a different way. I like your username too lmao.

-

If precision is king, be prepared to throw away much of what you commonly see in 3D printers. Many are designed with a vastly different set of goals - Price, ease of manufacture, ease of assembly, speed of assembly, ability to print parts.

Your aim should be to use linear guides on all axes and not have any cantilevers in your design. (As you identified with your Z axis, but the same applies to the X axis where the hotend is often cantilevered - A pair of horizontal rails is better than vertical rails for this)

Having ballscrews on all axes would massively increase weight, which means you might need to consider larger motors. For the X and Y axes, I'd suggest using a relatively low pitch ball screw (2-4mm pitch) and also consider a stepper driver with mid-band resonance compensation so that you can still maintain decent travel speeds. (http://www.geckodrive.com/featured-products/g214-55.html)

Rigidity is king here, consider using a welded steel box-section frame with the tubes filled with resin and the mating surfaces milled flat. 40mm square tubes would probably be a good start.

You mention that budget was not a concern, but I'd still suggest that you set yourself a rough budget - It will help you while designing and it will help others gauge exactly what they can and cannot suggest.

Thank you for your input!

I expected not to have to exceed $5,000 and will only spend a maximum of $10,000 on a system designed to be the same FDM/FFF Thermoplastic Hot-Gluegun CNC machine.

The speed of assembly is not a huge factor, however, it would be nice to have it done within the month. I prefer to CNC mill every part, if possible. I expected to be able to have Linear Guide Rails on the X and Y Still debating belt vs ballscrew. I believe I'll go with belt for X and Y and 2 ballscrews for 2 Z geared motors. High-Precision Steppers would allow be to just use a duet wifi which would be ideal, servos allow for faster XY travel and will allow for a completely closed loop. You are right about the added weight, If it was set up as a Prusa or MendelMax. If it is a Gantry where the X and Y remain at their Z height and only the Bed increases or decreases height, ballscrews would not add (subjective) too much more weight. I have read since I posted that, that good belts G2 Carbon (if I am not mistaken) have extremely low stretch after an initial adjustment/break-in period.

As for rigidity, welding is without a doubt superior, however would it be noticeable if I used extruded aluminum, or even stainless steel extrusion, with hardnened socket screws, precision right angle squares to align them, locktight, and the correct angle guides to increase rigidity further by creating truss style bracing from CNC milled metal, or even simple extrusion that is machined square and flat? I expected the compression strength to be enough for what I was doing with a build volume of as close to a cubic meter as I could. If it is a meter X and Y and half a meter Z, that'll do for now. I forgot to check what we have at the lab, it is either 40, 45, or 50 mm profiles, some are 4040 or 4545 (whatever it is) and some are 4080 or 4590 with a few pieces already cut to 45 degrees on both ends that I would remachine, because I can.

The gantry and all sides except the front will have full length bracing of some kind. Obviously, I must get the parts out that I send to the printer so the front will most likely have either a slide door(s) or hinged doors, either way they will be sealed doors so the chamber is humidity controlled. I was thinking of a system similar to vacuuming the air out, or a lot of the air out, expecting it to be able to heat up much faster. I thought about the foundry bricks, thinking of lining the inside with it to insulate it so it could also potentially act as an autoclave and an oven to anneal finished parts. I am interested in the exotic engineering thermoplastics such as Delrin, Nylon, Peek, Carbon filaments and any others I don't know about yet. This creates a problem for the motors and electronics so I will have to ensure to take that into consideration when storing and cooling the electronics, which also changes the thermocouples I am using which might change the board design so I am thinking of building a few versions of this, my expectation is 3.

I have an appointment with an applications engineer in a few days and I will bring my printer up there with some of the motors and links to discuss how to take full advantage of the Faulhaber motor company if I can.

-

Okay that budget unlocks a few things, but let's first discuss the frame.

If rigidity can be relaxed a bit (And reducing the moving weight by using belts on the X and Y axis), the there's no issue with extruded aluminium at all. I missed the bit where you mentioned that you already have a load of extrusion - In a CoreXY shape, 40x40 is a good size to use for the majority of the frame and the 40x80 parts can be used for the Y rails. As your build volume is quite large, you may want to consider extra bracing as you mention and possibly use some larger pieces such as 40x120. Your 1m span will need a thick linear rail which is supported, maybe a 25mm rail with a 20x20 or 40x40 aluminium bar behind it ?

Here's a nice picture of the top of the latest machine that the_digital_dentist is building: (Where he's used 1/4" tooling plate on top of some 40x40 aluminium extrusion)

http://forums.reprap.org/read.php?397,659980This is a Core XY design, but you could use the same sort of design with a more regular cartesian motion system if belt stretch is more of a concern than speed. (The trade of is more moving weight vs longer belts, I'm not sure which is best myself but I'll probably go with Core XY for my machine. Given the size of your machine, you might be better off with cartesian motion.)

Servo motors are only really helpful if you're going to be using 200-300W per motor, which you likely won't - For this application, open loop steppers will be fine. (And just as accurate)

One thing you might consider is moving the motors onto each axis and using a concept from the "servo belt" product - The idea is that you bond a belt to the aluminium rail with the teeth up, then have a second belt that runs along that. The carriage carries the motor and a pair of bearings, forcing the only a short stretch of unsupported belt and reducing belt stretch:

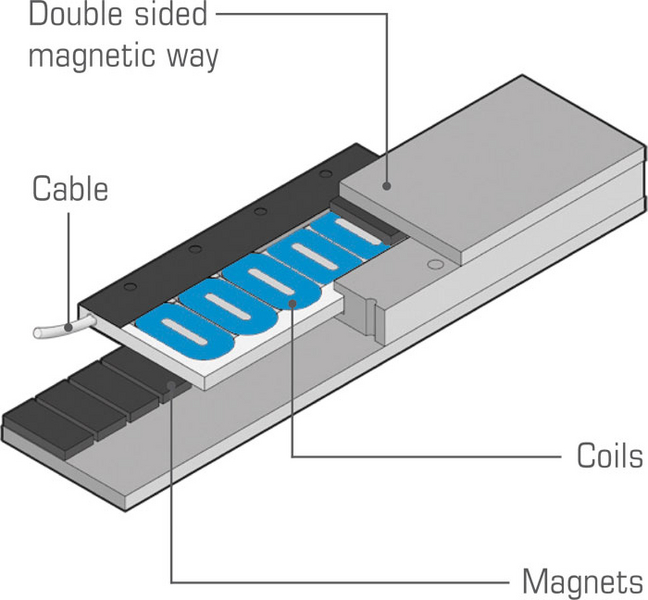

With your budget, you may also want to consider linear motors for the X and Y axis - This sort:

They will make make your axis design much simpler by doing away with the belts altogether. They can be thought of as flattened AC servo motors, but they work to produce straight line motion rather than rotating motion. The downside is cost, but you might be able to source some with your budget. As mentioned above, servo motors are overkill in terms of power, but linear motors will make things a lot simpler and remove any belt stretch.

-

[q. "I planned on trying to hack an inkjet to try to work, the viscosity of the thermoplastic concerned me. I was going to take a shortcut and copy/modify Stratasys's Liquifier pump first as I really would not have to change that much, my first thought was a high temp peristaltic pump."…

"Precison is MY current problem, My Kossel Mini works, however, I cannot really create too many function parts to my standards...which may be a tad ambitious."

Inkjet/Polyjet does not use Themoplastic. It uses UV curable polymers. These polymers can be really "nasty" to work with, they also can be prohibitively expensive. The design paradigm of the multifab was based on the openfab machine. The problem with having a machine that will do both cnc machining and printing is that for the printing you want low mass in the head and gantry with high acceleration movements and for machining you need high mass low acceleration for holding any kind of tolerance in the part. I don't believe a multi-machine utilizing the same gantry for both processes will ever be a valid solution. Next, when you finish comprehending Miss Kwans thesis on inkjet drive electronics you will find a few more problems. Hacking the Drop on Demand (DoD) control of the Epson inkjet heads is a real pita! I began to see that the Multifab was really a frankenprinter that many students at csail under the guidance of Matusik had used to write and prove their thesis and was not ever really a finished product that could be built for $10k; the head used in the 2013 thesis is not even available anymore.

-

[q. "I planned on trying to hack an inkjet to try to work, the viscosity of the thermoplastic concerned me. I was going to take a shortcut and copy/modify Stratasys's Liquifier pump first as I really would not have to change that much, my first thought was a high temp peristaltic pump."…

"Precison is MY current problem, My Kossel Mini works, however, I cannot really create too many function parts to my standards...which may be a tad ambitious."

Inkjet/Polyjet does not use Themoplastic. It uses UV curable polymers. These polymers can be really "nasty" to work with, they also can be prohibitively expensive. The design paradigm of the multifab was based on the openfab machine. The problem with having a machine that will do both cnc machining and printing is that for the printing you want low mass in the head and gantry with high acceleration movements and for machining you need high mass low acceleration for holding any kind of tolerance in the part. I don't believe a multi-machine utilizing the same gantry for both processes will ever be a valid solution. Next, when you finish comprehending Miss Kwans thesis on inkjet drive electronics you will find a few more problems. Hacking the Drop on Demand (DoD) control of the Epson inkjet heads is a real pita! I began to see that the Multifab was really a frankenprinter that many students at csail under the guidance of Matusik had used to write and prove their thesis and was not ever really a finished product that could be built for $10k; the head used in the 2013 thesis is not even available anymore.

You are right, I should finish reading it, I got distracted by the machine vision aspect and neglected to finish. You are also right, I know deep down a multimachine that I described is impractical, to say the least. Each machine should be specifically designed for its purpose. Ugh, my brain hurts. UV curable resin….I didn't realize that is how inkjets functioned....I have some studying to do. So I should postpone replicating Arcam's Electron Beam Melting....is what you are telling me....lmao. It sounds like an FPGA is the only (punny) logical way to go for hacking an inkjet and integrating machine vision and the DoD control in general into one control. Am I wrong in saying that? I have a lot of reading to do...I should try to intern at Stratasys....is it all patented? I'll spend a few days, again to say the least, researching. Would it be possible to use an AI agent to solve the problem of the DoD control?? AI is realistically at the point or damn close to it to be able to solve problems for us that are more complex....Why not attempt to solve a problem by developing an agent to do it for you?? With the open-source AI's I bet this is within the realm of possibility. If Autodesk's Dreamcatcher can generate drones that fit a given set of constraints...perhaps it would be easier to have an AI agent generate a control system or even a program...perhaps a solution set of polymer chemistry that could fit the constraint list?