Kinematic-mounting to prevent damage in collisions

-

My work involves an industrial motion platform that I'm converting into a 3D printer. The machine's motors have enough torque to destroy anything attached to the end-effector: hotend, mount, z-axis itself, etc.

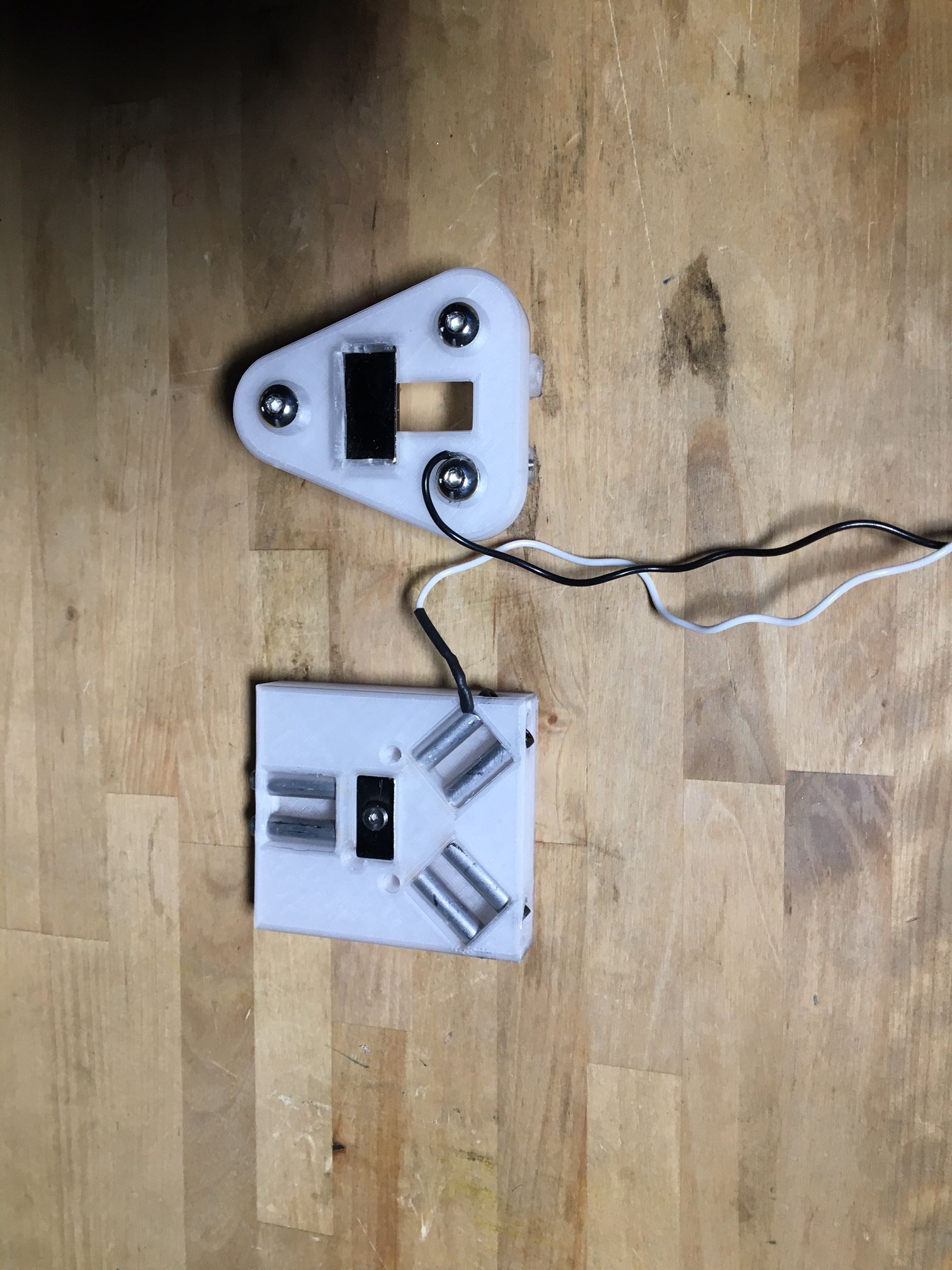

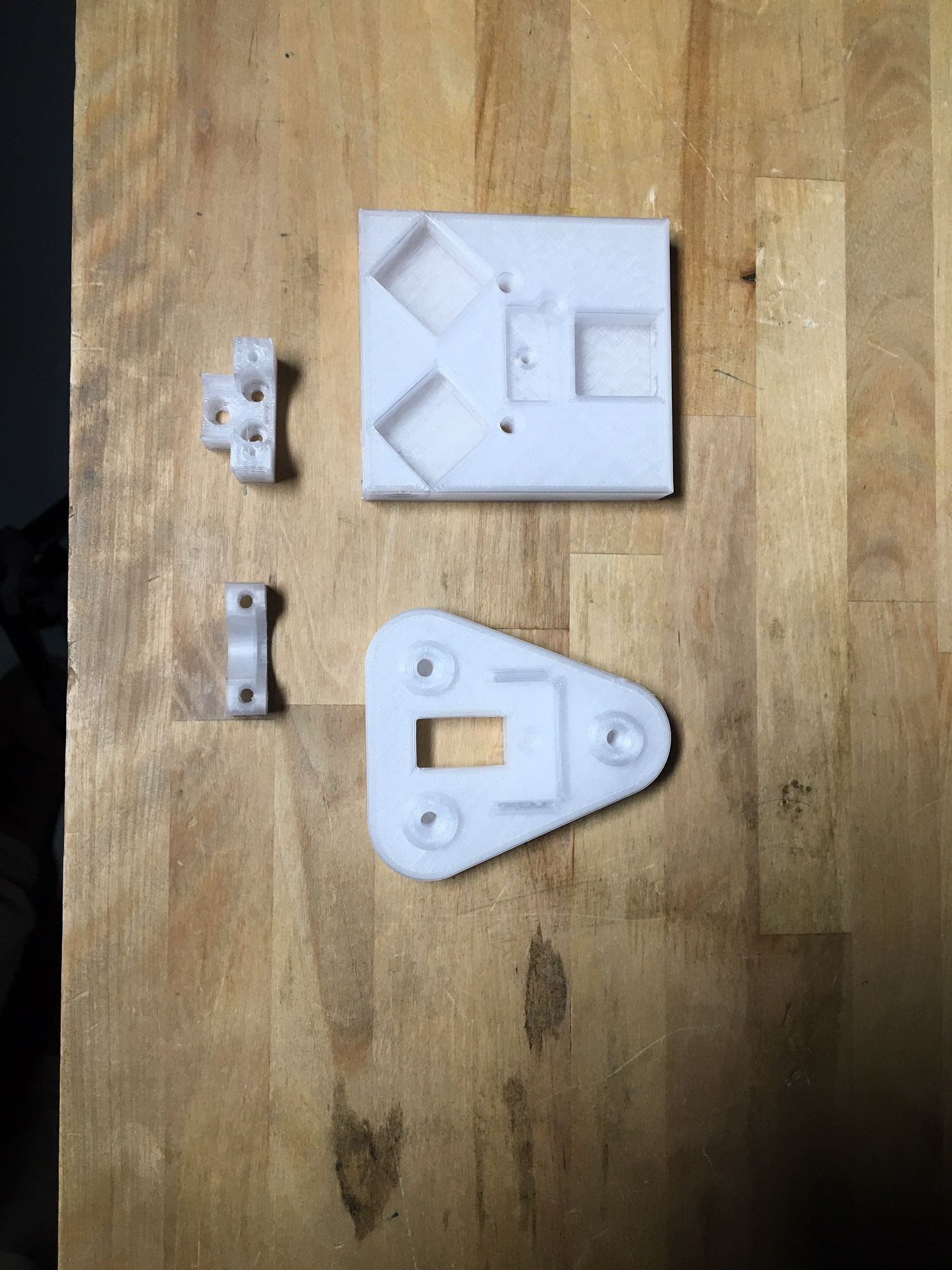

I designed (but haven't yet tested) a kinemtatic mount for the hotend that also acts as a normally-closed switch. The mount uses magnets to hold the two pieces together, and some round-head bolts and aluminum stand-offs create the kinematic mount.

My plan is to wire the black and white cables to an endstop header. If the print collides with something and the head is knocked out of place, the "switch" will open and the print or motion will be paused.

Let me know if you have any feedback!

-

You might want to be compatible with the existing "de-facto" industry standard for kinematic mounting of hot ends: The E3D mount.

It does use a locking pin, so is not designed to pop off under impact. Nonetheless, following their exact ball spacing would be a good idea. A magnet could still be used to allow things to pop loose.

Even better might be a mount that has a subplate for their pin, that subplate magnet to the main plate. Or optional sub plates.

The Jubilee printer (and numerous others) follow this standard. I mention them because their CAD is completely open: https://github.com/machineagency/jubilee you can get the kinematic layout from any of several parts.

-

Oh, and I'd run the sensor wire in a loop through all three touchpoints, just in case it got knocked partially loose.

-

@Danal Ah, great point about wiring.

Yeah choosing the Vee angles was mostly a guess as I was designing it, so I'll look into standardizing it. I actually like the idea of a spring-loaded pin to interface the plates, that way the hotend wouldn't just fall into the print if dislodged. But I'd need to make sure the Duet can detect a 'bump' through a momentary opening of the switch before the mount is pulled back into place.

-

I did design a kinematic mount with magnets (inspired by E3D and this thread: https://forum.duet3d.com/topic/9392/latching-magnetic-tool-changer). Although it's not the intended purpose of this system it does wonders against crashing the head and potentially damaging components.

The only downside is that the cables going to the extruder can exert strain onto it which means that at certain positions of the print head the remaining magnetic force can be very low. This again can lead to the print head detaching and denting (or cracking) the print bed. But a well-designed cable management can definetively solve this...

-

@Eumldeuml This is great, thanks for sharing it!