Core xy odd behaviour?

-

Wonder if anyone has encountered this before my core xy prints far superior in one direction than it does in the other when doing infill on layers.

Almost rough in one direction under the control of one stepper but when movement is switched to the other to do the next layer 90degrees to the previous its perfect.

Both belts are of equal tensionCould it be motor or a driver ? any thoughts appreciated

-

Unless those infills are on PERFECT 45s with relation to the square/rectangle of the CoreXY, it can't be one motor.

Both motors must move to make a straight line (on anything but a diagonal).

-

@Stevo Do the motors sound any different to each other in one direction compared to another? Can you describe this "roughness". Have you tried printing a cuboid rotated at 45 degrees on the build plate such that perimeters are printed using individual motors but the infill uses both? Any difference might show up better.

-

Good morning both and thank you for the replies,

So if you were to stand the printer on its side and both of the motors towards the bottom and the print to be done square as per facing the machine infill will be done on a diagonal.

I am printing a tray for the duet the 4 initial perimeter shells went down perfectly followed by the initial infill which is going from bottom left to top right with one of the motors rotation controlling the back and forth motion and the other motor controlling the side stepping to start the next line of infill and this went down perfectly as the initial shells ( smooth to the touch and reflective to view.

With the 2nd layer again outer 4 shells went down perfectly however this infill is now going 90 degrees to the previous layer from bottom right to top left. The motors now having swapped roles with each other doing the side step and the other controlling the back and forth movement.

Visually to look you can see and feel its rough by comparison to the first initial glossy layer !

Once layer 2 completed it again prints perimeter shells for the third layer perfectly followed by equally good infill same as layer one glossy.Thanks again for your input

-

@Stevo .....and answers to my questions?

-

It sounds like you're saying the second layer sounds rougher than the first. The first layer is printing on the smooth bed plate and the second is printing on the first layer which isn't so smooth. Maybe there's a little over extrusion on that first layer and the nozzle is bumping along on the ridges of the first layer as it prints the second layer.

If you print 3 or 4 solid layers, do the second, third, and fourth all sound the same?

-

@deckingman said in Core xy odd behaviour?:

@Stevo .....and answers to my questions?

Hey,

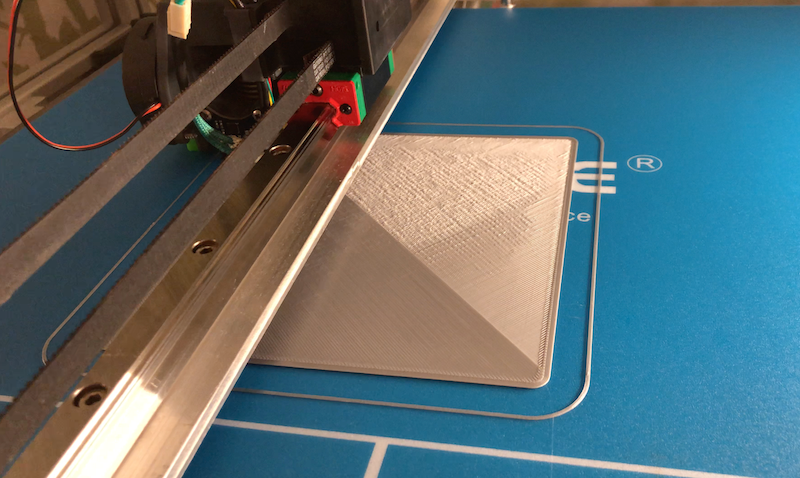

I cannot hear any differences between the motors and neither of them are noisy or hot in any way. I will be printing the lid for the box over the weekend and will rotate this on the bed as you suggest by 45 degrees.This being a snap shot of the third layer being printed which looks fine the rough area to be seen top right the layer in question as being rough.

I cannot hear any differences between the motors and neither of them are noisy or hot in any way. I will be printing the lid for the box over the weekend and will rotate this on the bed as you suggest by 45 degrees.

The box turned out ok in the end two small supports didn't make it as I had decided to try printing without any supports. but it will serve its purpose momentarily.