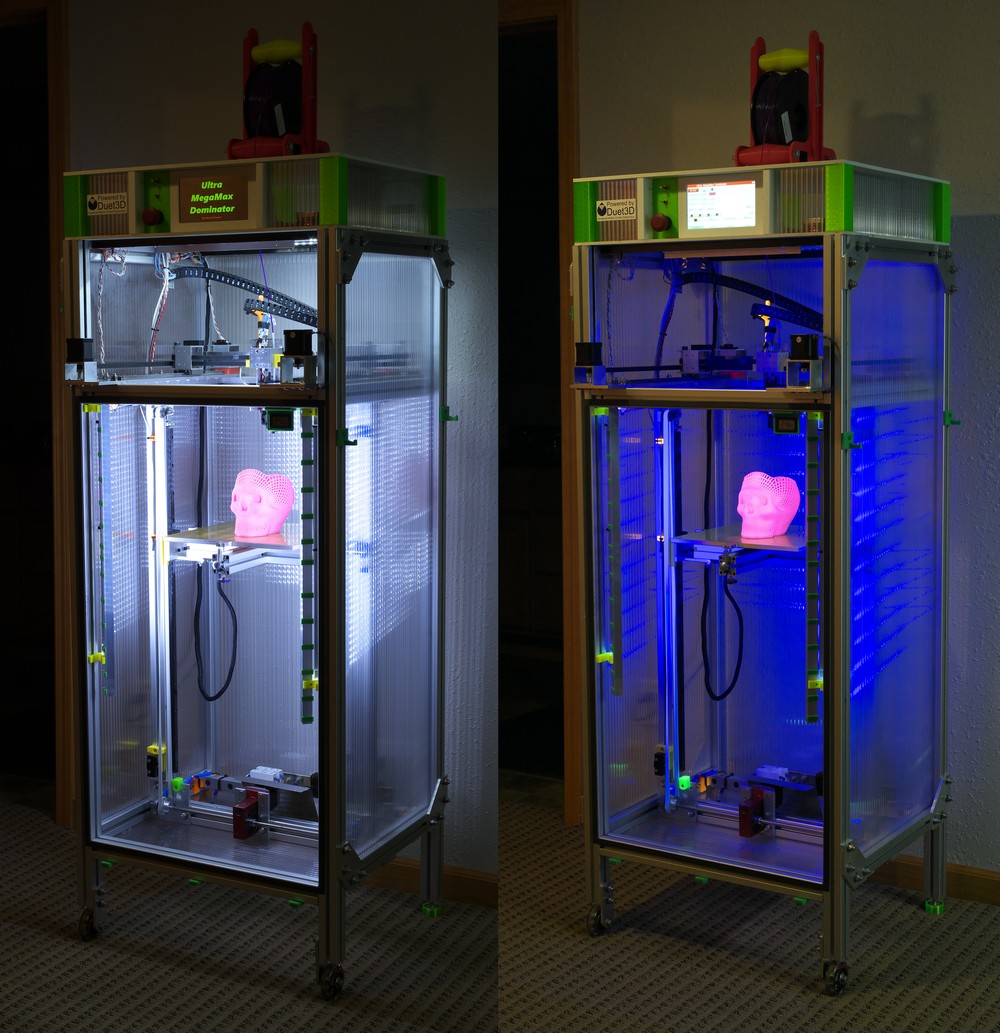

Finished my heated chamber for Christmas

-

Merry Christmas to you all.

Finally finished my heated chamber.

My Kossel XL+ is in the garage so is subject to cool temperatures overnight.

So I made a space frame using 16mm diameter aluminium tubing and corner pieces.

Covered with thermal bubble foil and made a sliding door and lid with polycarbonate cortex.

The chamber is heated with a 40W bar heater, controlled with a separate thermostat. Once it gets up to 20’C it switches off and the heat from the bed keeps it warm.

RPi zero W camera to monitor the print job from the comfort of my Lounge.

-

-

Looks nice!

A 40W heater, or 400W heater? 20C? What is the heater for? 20C won't help much with ABS...

-

The heater is 40W for the chamber enclosure Volume only.

Keeps the ambient temperature of the printer constant at 20’C even though the garage can get down to 5’C Overnight. It’s just to keep the system temp constant and not vary over 24 hours.

Helps with calibration and especially. I can set the set point much higher for ABS if required, with caution for the electronics (capacitors in PSU)

The bed and hot end heaters are stock. -

If you used the heater to get the temperature up to 50C or so you could print ABS reliably. That would probably take a higher powered heater.

My printer has a 500W heater to heat the 420 liter chamber to 50C and it takes about 20 minutes. The front doors on my printer aren't well insulated, but the sides, bottom and top are. I really should make a set of insulated front doors, too.

That dual layer PC used for the walls provides good insulation and nice visual effects when the machine is lit up.

-

Yes, my door and lid (Double layer) are corrugated polycarbonate sheet so should offer some insulation.

I have a thermal camera so will look for leaks.

All seams are sealed with fluffy draught excluder self adhesive strips. -

Your enclosure looks so well engineered and beautiful!

I would be proud to have that in my lab at work.A bit beyond my Home budget I fear.

-

@JuJuDelta Thanks! I used 8mm thick dual layer PC that fits very nicely into the 8mm wide slots in the 4040 t-slot. It looks nice, but can make working on the machine a little troublesome. I have reworked a couple parts of the Z axis to make it easy to work on without removing any of the PC panels, and I never have to work on the XY mechanism, except the extruder carriage where I do a lot of experimenting with extruders and hot-ends. It's a pretty low maintenance machine, partially because I used very few plastic parts in the mechanism.

It wasn't nearly as costly as you might think. I built it using a lot of surplus parts and materials gathered over about a year, so it cost a little over $1k all-in. I did the limited amount of machining myself at the makerspace.

I find that setting the chamber to 50C allows me to print ABS without worrying about it splitting or warping. It's also not hot enough to cause problems for the motors or other mechanical parts. The XY motors are outside the chamber, but they didn't really have to be. The electronics are all in the top of the machine, away from the heat.