Dual Z tilts after time (fast)

-

@jens55 said in Dual Z tilts after time (fast):

Would you not get 'wind up' of the mechanics if you have two motors connected like that?

I would have thought so but perhaps it might not be significant?

-

Ok i tryed the independent Leadscrews but it looks like 1mm correction isn't enough.

G32 Error: Some computed corrections exceed configured limit of 1.00mm: -2.080 2.814 -

-

@Veti Thx i tryed 5mm now and it works.

From now on i should use in my start Gcode before every Print G32 S2 right?

-

@AS-3D-Druck said in Dual Z tilts after time (fast):

From now on i should use in my start Gcode before every Print G32 S2 right?

it depends on your bed.

if its perfectly flat yes.if not use

G32 followed by G29 -

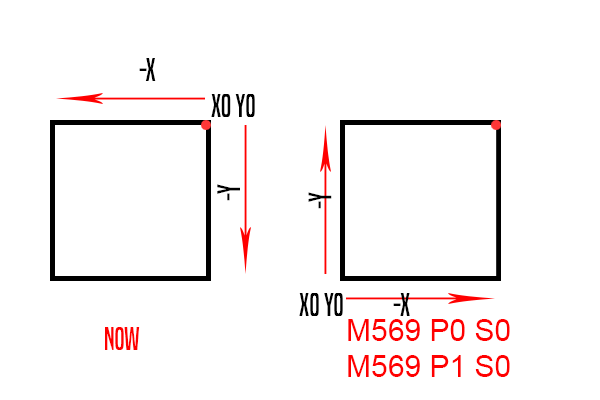

Ok i don't know what happend but now my Homing has flipped from front left to back right. (Stall Detection)

I don't know why it worked yesterday and now not.

-

do the normal moves are in the correct direction?

if yes -> check your homing file moves

if no -> change direction of motors in the config -

This is how it homes

This is how i home all:

; Lift Z relative to current position G91 G1 Z10 F6000 S2 G90 M913 X50 Y50 ; reduce motor current to 50% to prevent belts slipping G91 ; use relative positioning ; X G1 S1 X-500 F4000 ; move the X to max until it detects the min Point G92 X0 ; set X min Point G1 S1 X30 ; move X away from min Point M400 ; Y G1 S1 Y-500 F4000 ; move the X to max until it detects the min Point G92 Y0 ; set X min Point G1 S1 Y30 ; move X away from min Point G90 ; back to absolute positioning M913 X100 Y100 Z100 ; motor currents back to normal ; Z G1 S1 X168 Y95 F2000 ; put head over the centre of the bed, or wherever you want to probe G30 ; lower head, stop when probe triggered and set Z to trigger height G91 ; relative mode G1 Z10 F6000 S2 ; raise head 4mm to ensure it is above the Z probe trigger height G90 ; back to absolute modeconfig: https://pastebin.com/gFtv1wM7

-

@AS-3D-Druck Do the motors still move in the right correct directions? i.e. when you do G1 S1 X-500, does it still move to the left? And when you do G1 S1 Y-500, does it still move to the front?

-

@deckingman said in Dual Z tilts after time (fast):

@AS-3D-Druck Do the motors still move in the right correct directions? i.e. when you do G1 S1 X-500, does it still move to the left? And when you do G1 S1 Y-500, does it still move to the front?

It does not move at all in - only in+ but there is no room for any Movement so it cares in the Extrusion.

The coordinates are set wrong for some reason

btw. i added on my Post before the config.g

config: https://pastebin.com/gFtv1wM7 -

You might want to consider joining the two leadscrews with a belt

-

@AS-3D-Druck said in Dual Z tilts after time (fast):

It does not move at all in - only in+ but there is no room for any Movement so it cares in the Extrusion.

this does not answer the question.

move the extruder to the middle

issue M564 H0

and see if the movement are as expeded.

ie x - goes left x+ goes right -

@Veti No it does nit everything in - isn't working except i use M564 H0 than i can manualy move it to the middle but homing does still not work anymore.

-

@AS-3D-Druck Starting with the print head in the middle step through your homing fie one line at a time but you can ignore the Z axis for now. So send M913 X50 Y50 to reduce the motor currents. Then send G91 to set relative positioning. Then send G1 S1 X-500 F4000 and tell us if the head moves to the left as it should or does it do something else?

-

@deckingman said in Dual Z tilts after time (fast):

@AS-3D-Druck Starting with the print head in the middle step through your homing fie one line at a time but you can ignore the Z axis for now. So send M913 X50 Y50 to reduce the motor currents. Then send G91 to set relative positioning. Then send G1 S1 X-500 F4000 and tell us if the head moves to the left as it should or does it do something else?

Ok maybe i found the Issue here:

; X G1 S1 X-500 F4000I had to send 3-4 times this command until it started to move to the min point.

Bevore that i heared only a tock after i send the command.... like there was already something that the stall detection noticed.I don't know my Motors are rated for 1.3A and i set them to 1A and reduced it to 50%.

Now i played with M915 and increased the S Value from 3 to 8 to 10.It looks like that was the Problem.

Thx alot for the help and i will try my next print with this new "Setup".

You're Guys are awesome.