[not yet solved] Tevo Little Monster DuetWifi errors

-

I will try to control all these points but it is not obvious to be precise. By the way, what is the order of magnitude XX.XXXmm?

When I do my calibrated to find the value G31 ZX and that I launch my impression I always 0.20mm too high. So I change the value of G31 Z0.687 + 0.20 to have a 1st layer that hangs and rotates between 0.25 and 0.35mm.

I controlled the distances between the top of the printer and a point of the carts that had different values. I now have about 4cm everywhere I will try to do this with the caliper.

But it did not really change the quality of my first layer (Nozzle 0.8mm)

L'imprimante

-

dc42

what should be changed as parts to solve this problem of geometry? -

Try this guide and join this TLM group, https://www.facebook.com/groups/TEVO.Monster.Delta.Owners/

-

I thank you, I will study with precision.

-

Hello,

I just control the angle of the towers and I do not have the same exactly the same value. This can be my geometry problem?

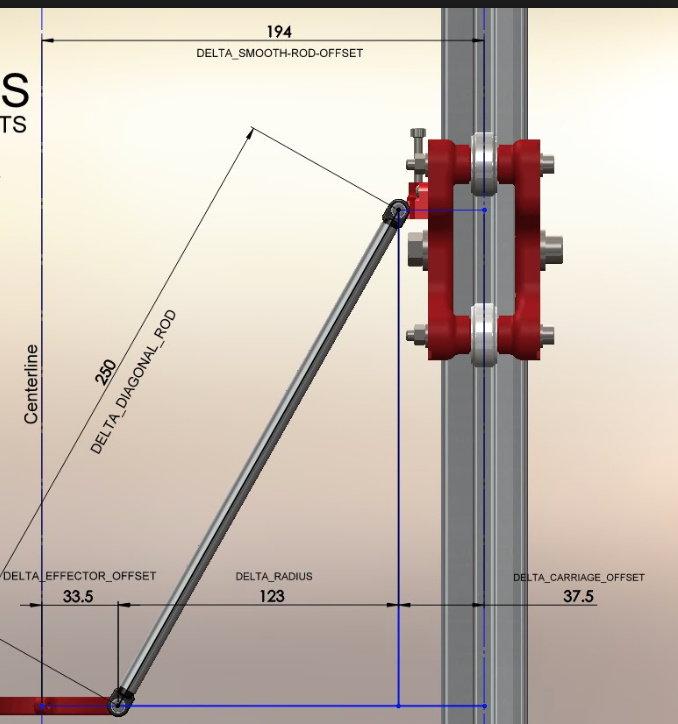

I will now control the length of my Delta Diagonal Rod -

Auto calibration will sort out the tower angles for you.

-

I think it would be complementary to bring illustrations and or videos to the Duet manual on the essential control points of a perfect machine calibration. Especially for the illiterate technicians like me.

-

I still do not understand the procedure of calibrating a delta with Duet but I will not give up. how to disable auto calibration? I think I can have a 1st more homogeneous without the self calibration. I checked everything manually and my tray with borosilicate glass is really flat.

-

My geometry problem may come from this problem (see video)

When I make a home and I go back 5mm to put out the leds of the endstops I always have an endstop that stays on.

I change endstop, screwed to racemess and unscrewed to lengthen the head of the screw, set the ten micro to have exactly the same distance between the three cart and the problem is the same, the led remains lit while the trolley is perfectly in front of the optical fork. When I push the cart slightly, the led goes out.Can you help me understand this problem?

https://www.icloud.com/iclouddrive/0od7VaaViYMMcV5_HiBiwm8dA#IMG_5224

-

Hello,

I have exactly the same problem as you.

I have an identical printer is impossible to turn off the limit switches, -

Tu es Français non?

Tu as une couche de hauteur homogène avec ta TLM?you have a 1st layer of uniform height with your TLM?

-

@rafb Paint the flags with something that IR doesn't go through. Many plastics are transparent to IR.

-

@rafb

Oui je suis bien Français...

Pour la 1er couche c'est pas trop mal à condition que je n'imprime pas quelque chose qui est une trop grande surface -

@stephen6309 Hi, thank you for your proposal but it is a screw without black head

-

This post is deleted! -

@rafb sounds like you need to make it wider so that it definitely blocks the IR on the Endstops sitches

-

@synergy41 Ça m’a fait tilt quand tu as mis le lien les imprimantes 3D.

Je pense pas que le problème vienne Du réglage de la mécanique. J’ai tout réglé au pied à coulisse. Je vais l’installer micromètre À la place du hotend Et vérifier la planéité du plateau. Si tout est parfaitement plat, je ferai une vidéo et demanderai de l’aide à dc 42 pour comprendre d’où vient le problème. Qu’en penses-tu as-tu d’autres propositions? -

@rafb I think at home my tray is not really Top Top.

I have to find a glass to try to see if I can print a larger area.

What annoys me the most is the problem of limit stop. -

yes the problem of endstop optical is a known problem with the duet. This is probably what leads to the problem of geometry and therefore the impossibility of having a suitable first layer. I have a borosilicate glass and I use a Thickness Gage to adjust the space between my nozzle and the boro glass bed. My bed is on 3 spring.

I really have a hard time understanding? Having a 350mm bed to print pieces of max 100mm drives me crazy !! -

@rafb said in [solved] Tevo Little Monster + DuetWiFi + DuetTouch7" errors:

yes the problem of endstop optical is a known problem with the duet.

What problem are you referring to? The only problem I am aware of is that some optical endstops are designed to work with a 5V supply and don't work properly on 3.3V. The common ones can be fixed by changing one resistor (the one that feeds the IR emitter in the slotted opto switch). If it is an SMD resistor, soldering another resistor on top (to connect it in parallel) is easier because then you don't need to remove the old one.