Bed leveling mesh calibration not working

-

M208 X0:524 Y0:600 ; Xcarriage move, Ycarriage move ;********************other stuff ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X525 Y601 Z800 S0 ; set axis maxima ;********************other stuff M557 X20:520 Y50:550 S50 ; define mesh gridThat is, assuming that homing works right, at least. My grid is big, you need to adapt. It may be that my M208s are redundant, but you got the ideea. This is what configuration did for me, and I just modified it a little.

-

@soare0 It is really best to share the full files as requested above, makes it much easier for folks to be able to understand what is happening.

-

@gloomyandy

Indeed, but thats not me who need to share the full file dear... -

Oh ya I forgot more information

Ender three with bltouch using a btt skr2 mainboard I think running reprap, the only thing I’ve gone and changed is the M557

-

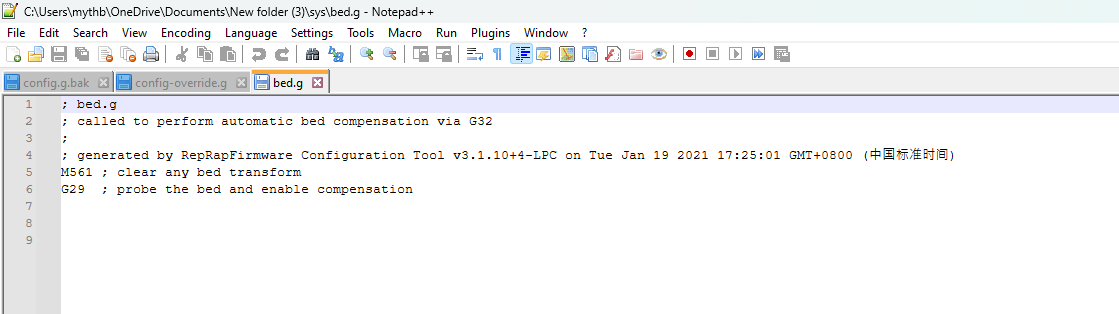

@Mythbear74 As above please upload your config.g config-override.g, mesh.g, and bed.g files. Without them there is not much we can do to help you.

-

All right, I’ll have in a bit

-

-

Here it is

-

@Mythbear74 Why not post here, as code?, Unless is for some secret military project, but then... google drive?

-

Yeah, like I said before I’m new and this is like my first time using the thing also, I don’t know how to find this tab when signing into this account

-

@Mythbear74 I paranoidly may think that on google drive you posted some infected files, if I would judge your answer. This... tab you speak about, will appear when you reply, at least on a normal computer.

Again, here is the explanation, in included image. If you still cant figure it, maybe you should make your 3d printer a gift for somebody. Dont mean to be ... mean, but just honest.

-

So do you want me to send the code again but in this other way

-

You can drag and drop the config.g onto the post box to upload it here. Or even copy and paste the text here.

-

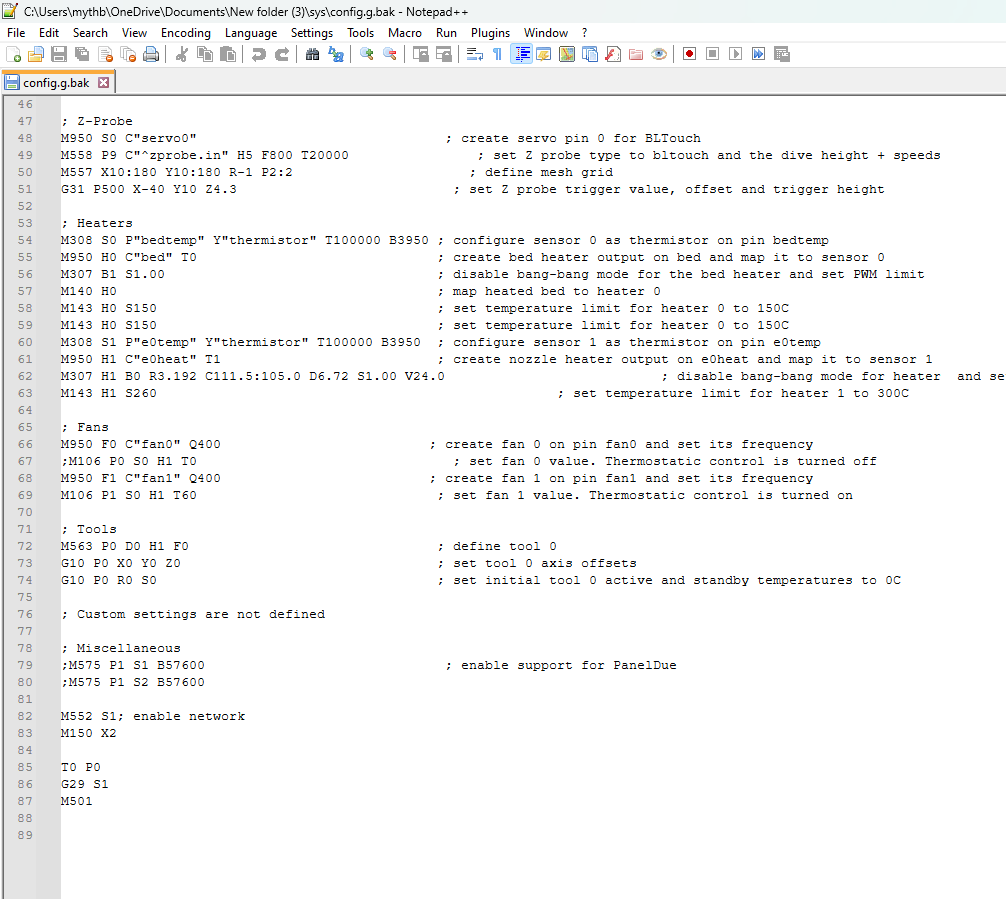

Here is my config.g it was having trouble sending the file

; Configuration file for SKR-E3-RRF (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.10+4-LPC on Tue Jan 19 2021 17:25:01 GMT+0800 (中国标准时间) ; General preferences M950 P1 C"SP" M42 P1 S1 G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 PAsa3DPrinter ; set printer name ; Network M552 S-1 M552 S0 M587 S"namllok" P"7856501514" M552 S1 M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes forwards using default driver timings M569 P1 S0 ; physical drive 1 goes forwards using default driver timings M569 P2 S1 ; physical drive 2 goes forwards using default driver timings M569 P3 S0 ; physical drive 3 goes forwards using default driver timings M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E93.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min) M201 X600.00 Y600.00 Z20.00 E350.00 ; set accelerations (mm/s^2) M906 X700 Y700 Z650 E750 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X230 Y230 Z250 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop ;M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop ;M591 D0 P7 C"e0stop" S1 R50:130 L7.0 E10 ; Z-Probe M950 S0 C"Servo0" ; create servo pin 0 for BLTouch M558 P9 C"^probe" H5 F800 T20000 ; set Z probe type to bltouch and the dive height + speeds M557 X10:180 Y10:180 R-1 P2:2 ; define mesh grid G31 P500 X-40 Y10 Z4.3 ; set Z probe trigger value, offset and trigger height ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bed" T0 ; create bed heater output on bed and map it to sensor 0 M307 B1 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 R3.192 C111.5:105.0 D6.72 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S260 ; set temperature limit for heater 1 to 300C ; Fans M950 F0 C"fan0" Q400 ; create fan 0 on pin fan0 and set its frequency ;M106 P0 S0 H1 T0 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q400 ; create fan 1 on pin fan1 and set its frequency M106 P1 S0 H1 T60 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous ;M575 P1 S1 B57600 ; enable support for PanelDue ;M575 P1 S2 B57600 M552 S1; enable network M150 X2 T0 P0 G29 S1 M501

-

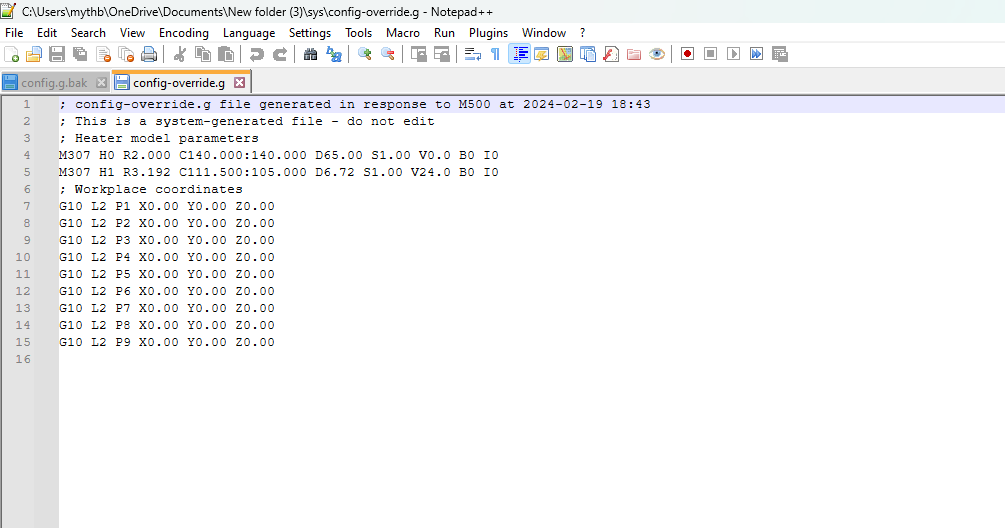

Heres the others

; config-override.g file generated in response to M500 at 2024-02-19 18:43 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 R2.000 C140.000:140.000 D65.00 S1.00 V0.0 B0 I0 M307 H1 R3.192 C111.500:105.000 D6.72 S1.00 V24.0 B0 I0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.1.10+4-LPC on Tue Jan 19 2021 17:25:01 GMT+0800 (中国标准时间) M561 ; clear any bed transform G29 ; probe the bed and enable compensation

I don't have a mesh.g

-

@Mythbear74

I see you have no ideea what you are doing there. Dont know why you used R parameter. I think that is for a delta printer.

If you understand what I am saying (as I think you are translating online from chinese), try something like this:M557 X10:180 Y10:180 S40You will have a 16 point mesh bed.

However,M557 X10:180 Y10:180 S4:4may cover better the area, also, with 16 points mesh bed.

-

No I’m not from China. It’s just this thing is actually a gift to me and I can just got thrown it after they set it up. I will try putting in that code and then give you an update. thanks

-

All right, so I tried both those inputs, but it did the same problem. Is there any more information you need?

-

@Mythbear74

If you will put here the files, either as code or copy pasted, as well as a short clip with the problem, I am sure that they will be many to help much better than me. I am sorry, but it is difficult otherwise.

PS. It is not a problem if you eventually are from China, I just expressed the feeling that you do not understand what we are saying, wich is usually because a language barrier.

PS2. Do not insert those files as images/screen captures, as probably some of them will not fit on your monitor (I see that your config files start at line 46). Unless ... you will rotate the monitor to portrait, if you insist with screen captures.

PS3. There is also the possibility that the printer has an hardware issue, so.... files and clip needed.

PS4. Normally, it should have been a difference between your M557 and mine. Maybe you can show how the original M557 was (assuming it was the original).

PS5. If you do not try to do mesh, the printer works right? -

Honestly at this point I’d rather like to know how to completely eradicate the height map system so it forgets about it.

PS, I am not from china I am in the US and I am quite new to this