Duet 2 Wifi 3 Heater control using bed output + messed up tools

-

Does not work properly either.

I think maybe my heaters, sensors & tools is mismatching somehow.

When i PID turned heater 3 it didnt heat properly either.

-

I suspect the firmware is confused because it is not a complete configuration.

Maybe you can describe what you want to do.

As I understand it, you only want to control 3 heaters? -

Yes i want to control just 3 different heaters (all for an extruder/hotend), one from the bed output on the duet. two others from the regular E outputs.

and all with 3 different sensors - PT100 on the duet aswellThen i want to map the 3 sensors and heaters to heater 1 2 and 3 , but it keeps turning up as they are mixed up, or one of them on the bed heater output...

Looking something like this:

M308 S0 P"spi.cs3" Y"rtd-max31865" ; configure sensor 0 as PT100 on pin spi.cs3

M950 H0 C"bedheat" T0 ; create nozzle heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H0 S280 ; set temperature limit for heater 0 to 120CM308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs1

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280CM308 S2 P"spi.cs2" Y"rtd-max31865" ; configure sensor 2 as thermocouple via CS pin spi.cs2

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280CI am quite confused of the P1, P2 and how to configure them to the correct "tool" in the dwc and duet display - so i am sure my heaters match etc.

M563 P1 H0 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0CM563 P2 H1 F0 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0CM563 P3 H2 F0 ; define tool 3

G10 P3 X0 Y0 Z0 ; set tool 3 axis offsets

G10 P3 R0 S0 ; set initial tool 3 active and standby temperatures to 0C -

@mikep91

The tool count starts with 0.

So P0 Is tool1 -

Also make sure your firmware is update and that DWC version matches. You should also update your paneldue firmware.

-

Paneldue is up to 1.25 now this was updated and works great!

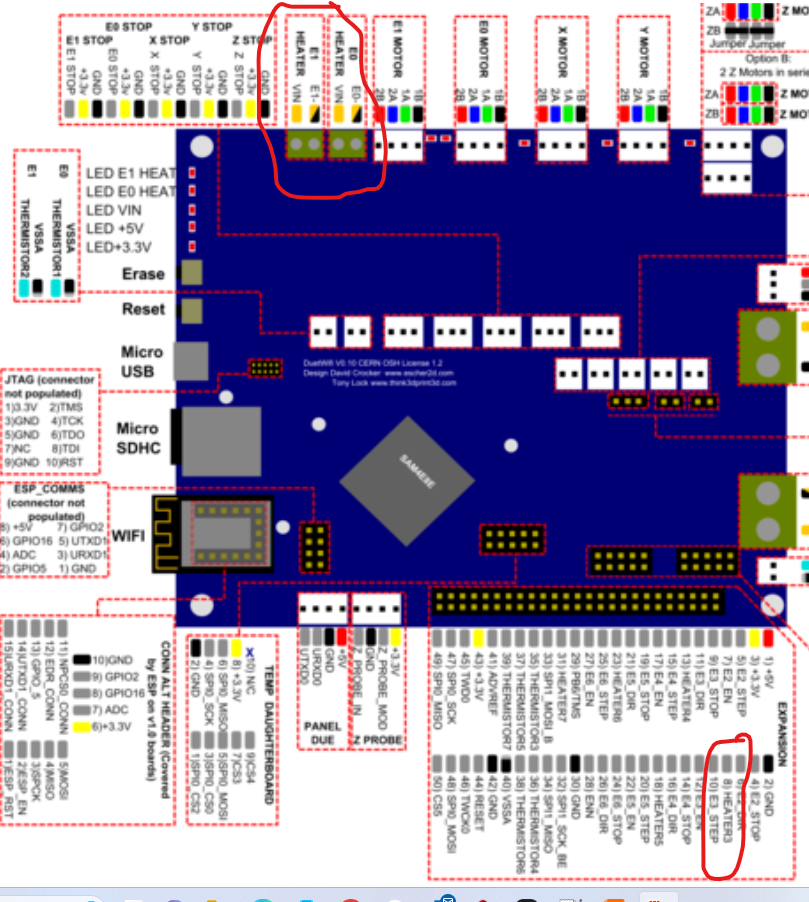

Looking at the PT100 - which side is spi.cs1 & which side is spi.cs2? when i plug another one on top - i suppose that becomes spi.cs3&4?

-

The sides have silk screen labels of RTD1 and RTD2.

And yes when you stack two of them the next ones are spi.cs3 & 4. -

@mikep91 said in Duet 2 Wifi 3 Heater control using bed output + messed up tools:

Paneldue is up to 1.25

Should probably update to the 3.x firmware there as well.

-

The 1.25 works on 2x setups with only 2 heaters - I am only having problems assigning the heaters on the 3rd setup that needs 3 heaters.

Could a problem be that i start up by assigning H0? Looking at the duet display - i am using the 3 marked heaters. - e0heat - e1heat and H3 "bedheat"

-

Why are you using the expansion header? Why not the actual bed heater output?

-

It is for controlling a 3 heater hotend (Dyze Pulsar)

Therefor I am turning off the bed heater - but my tool mapping seems to be wrong so i keep getting the 3rd temperature on the bed heater output instead of a 3rd tool - and at the same time I'm get them mismatched somehow....

Will do some wiring checks and numbering of wires tomorrow hopefully sort it up.

Am not using heated bed - so I know I should do a H-1 to turn it off. but the mapping seems to go on that tool

-

Are you using a heated bed, or not?

-

No - not controlled off the DUET - duet is only supposed to be controlling 3 heaters in one hotend

Elaborated in answer above

-

@mikep91 said in Duet 2 Wifi 3 Heater control using bed output + messed up tools:

Am not using heated bed - so I know I should do a H-1 to turn it off. but the mapping seems to go on that tool

If you're not using a bed heater you can use the output for your 3rd extruder heater, then you don't need to use the expansion headers, which aren't really intended to be used directly by a heater.

If you don't define a bed heater you don't need a H-1 to disable it.

-

Makes sense and would be alot better as the connections on the expansion is quite poor compared to the bed and extruder connections.

How would the M command look for mapping the 3rd heater to the bed instead of the expansion?

M308 S1 P"spi.cs3" Y"rtd-max31865" ;

M950 H1 C"bedheat" T0 ;

M307 H1 B0 S1.00 ;

M143 H1 S280 ;Something like this - whilst not using H-1 to cancel it out?

-

So if I understand your setup, and I'm not sure that I do, you'd have something like this for a single tool, using 3 heaters together, and no bed heater, with PT100 temp sensors.

; Heaters M140 H-1 ; disable heated bed (overrides default heater mapping) M308 S0 P"spi.cs1" Y"rtd-max31865" ; configure sensor 0 as PT100 on pin spi.cs1 M950 H0 C"bedheat" T0 ; create nozzle heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H0 S280 ; set temperature limit for heater 0 to 280C M308 S1 P"spi.cs2" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs2 M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"spi.cs3" Y"rtd-max31865" ; configure sensor 2 as PT100 on pin spi.cs3 M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H0:1:2 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H0:1:2 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Miscellaneous T0 ; select first tool -

Yeah im sorry for being not very precise - I am using a pellet hotend on a robotic arm, so the duet is only to control the heaters. But it has 3 heat zones - so i would need individual control of each heat zone mapped to a specific sensor.

Would this give me 3 individual heaters to control on the duet display?

I will do a test first thing tomorrow morning with this - thank you!

-

Does the Duet even need to know it's a tool? If it's only doing heater control and no motion planning I think you could leave out the tool and fan definition.

-

No it does not actually - i thought these commands were what gave me temp control on the display

-

Hello again Phaedrux -

When testing out the config you posted yesterday.

When setting the temperature on the display - I am getting the error "wrong tool"...

How would i correct the tool allocations?

I can turn them on using macros and M commands but not on the display....

Cheers