DWC Duet Web Control 3.4.0-rc2 no extrude or retract

-

Post your config. Last time I saw this the tool didn't have an extruder motor assigned.

-

@phaedrux

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Valkyrie 3030 V001" ; set printer name

M669 K1 ; core xy

G29 S1 ; Set Units to Millimeters; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.0 S1 ; physical drive 0 goes forwardsM569 P0.1 S1

M569 P0.1 S1 ; physical drive 1 goes forwardsM569 P0.1 S1

M569 P0.2 S1 ; physical drive 2 goes forwards

M569 P0.3 S1 ; physical drive 3 goes forwards (spare)

M569 P0.4 S1 D3 V30 ; physical drive 4 goes forwards D3=stealthchop

M569 P0.5 S0 D3 V30 ; physical drive 5 goes backwards

M569 P0.6 S1 D3 V30 ; physical drive 6 goes forwardsM584 X1 Y0 E2 Z0.4:0.5:0.6 ; set drive mapping FL,FR,RC

M350 X16 Y16 I1 ; configure microstepping with interpolation

M350 Z16 E16 I1

M92 X80.00 Y80.00 Z320.00 E260.00 ; set steps per m

M566 X500.00 Y500.00 Z800.00 E100.00 P1 ; set maximum instantaneous speed changes (mm/min)

M203 X8000.00 Y8000.00 Z1000.00 E400.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z200.00 E250.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1400 I10 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima "Travel Area"

M208 X270 Y240 Z405 S0 ; set axis maxima "Travel area"; Endstops

M574 X1 S1 P"!io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in

M574 Y2 S1 P"!io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in

;M574 Z2 S2 P"!io4.in" ; != invert signal

M574 Z2 S4 ; configure sensorless endstop for high end on Z, 1 = low end, 2 = high end. S4 multipule motors

M671 X-34.4:296:132.5 Y0:0:296 S25 ; leadscrews at front left,front right, rear Center s= max correction factor must be in same order as M584; Sensorless config

M915 P0.4:0.5:0.6 S5 R0 F0 H200 ; Lower values less sensitive S3, F filter, R =Action; Z-Probe

M558 P8 C"!io3.in" H5 F600 T18000 A30 S0.03 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 Z0.5 ; set Z probe trigger value, offset and trigger height bigger the posative number the closer to the bed

G31 P500 X26 Y6 ; set x,y trigger value, offset and trigger height

M557 X30:270 Y10:250 S40 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed T°C" ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"out0" T0 Q10 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 R0.140 K0.103:0.000 D43.19 E1.35 S0.90 B0 ; PDI info for 8mm aluminium bed 700w Heater NTC 100K 3950

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4267 A"Extruder T°C" ; configure sensor 1 as thermistor on pin e0temp (104gt2)

M950 H1 C"out1" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R3.548 K0.733:0.000 D4.96 E1.35 S1.00 B0 V23.9 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out3" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

M98 P/macros/3zhome -

@moth4017 You don't have a T0 at the end to select Tool 0. Your M98 needs to be changed to M98 P"/macros/3zhome"

-

@moth4017 said in DWC Duet Web Control 3.4.0-rc2 no extrude or retract:

G29 S1 ; Set Units to Millimeters

G29 S1 does not set units to mm. It loads the heightmap, which shouldn't happen in config.g anyway. Best to remove that line.

-

@phaedrux removed G29, can you think of any reason why the extrude/retrack may not be working?

-

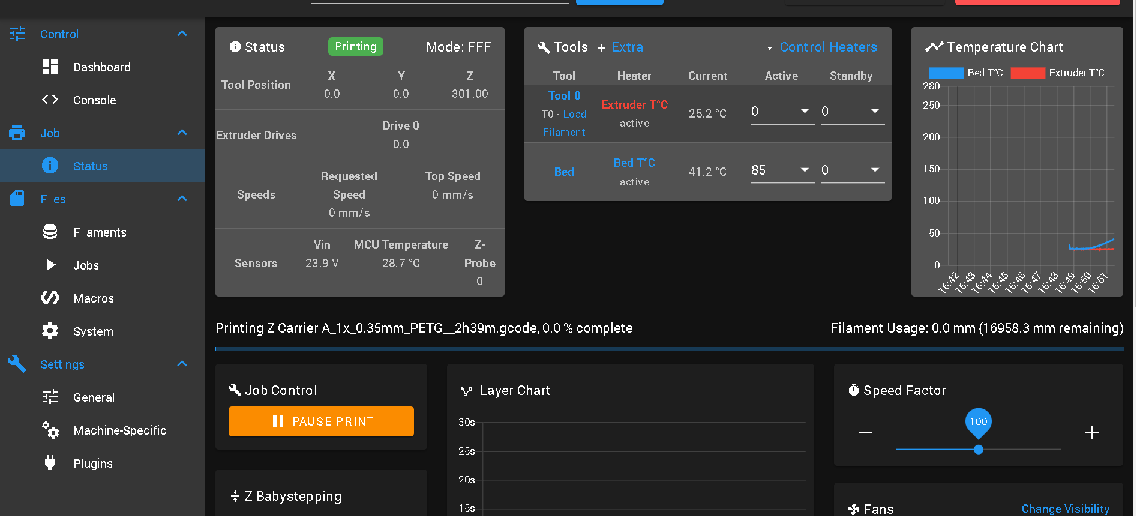

Is the tool selected? Your screen shot doesn't show the full window so it's hard to tell.

Can you share the results of M122 and M98 P"config.g"

It seems you're using a mini5+? But you have 6 drivers configured...

-

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 Mini 5+ version 3.4.0rc1 (2022-02-09 10:27:22) running on Duet 3 Mini5plus WiFi (standalone mode)

Board ID: 3R9YY-6T9RL-D65J0-40KMN-2UW2Z-RHYT0

Used output buffers: 3 of 40 (14 max)

=== RTOS ===

Static ram: 103652

Dynamic ram: 109368 of which 12 recycled

Never used RAM 28608, free system stack 154 words

Tasks: NETWORK(ready,12.6%,240) HEAT(notifyWait,0.0%,338) Move(notifyWait,0.0%,292) CanReceiv(notifyWait,0.0%,942) CanSender(notifyWait,0.0%,356) CanClock(delaying,0.0%,339) TMC(notifyWait,1.1%,114) MAIN(running,85.3%,428) IDLE(ready,0.1%,29) AIN(delaying,0.8%,264), total 100.0%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 00:04:03 ago, cause: power up

Last software reset at 2022-03-01 07:23, reason: User, GCodes spinning, available RAM 28608, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

MCU revision 3, ADC conversions started 243877, completed 243877, timed out 0, errs 0

Step timer max interval 955

MCU temperature: min 19.6, current 29.8, max 30.4

Supply voltage: min 23.7, current 23.9, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 22127, writes 9, timeouts 0, DMA errors 0, CC errors 0

Driver 1: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 22127, writes 9, timeouts 0, DMA errors 0, CC errors 0

Driver 2: pos 96320, standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 22126, writes 9, timeouts 0, DMA errors 0, CC errors 0

Driver 3: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 22126, writes 9, timeouts 0, DMA errors 0, CC errors 0

Driver 4: pos 0, standstill, SG min 152, read errors 0, write errors 0, ifcnt 16, reads 22120, writes 16, timeouts 0, DMA errors 0, CC errors 0

Driver 5: pos 0, standstill, SG min 16, read errors 0, write errors 0, ifcnt 16, reads 22119, writes 16, timeouts 0, DMA errors 0, CC errors 0

Driver 6: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 17, reads 22118, writes 17, timeouts 0, DMA errors 0, CC errors 0

Date/time: 2022-03-02 16:52:41

Cache data hit count 459070420

Slowest loop: 118.95ms; fastest: 0.08ms

=== Storage ===

Free file entries: 9

SD card 0 detected, interface speed: 22.5MBytes/sec

SD card longest read time 13.8ms, write time 11.5ms, max retries 0

=== Move ===

DMs created 83, segments created 3, maxWait 624ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 0 is on, I-accum = 0.2

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is doing "M190 S85 " in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== CAN ===

Messages queued 2193, received 0, lost 0, boc 0

Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 18 (min 18), ts 1220/0/0

Tx timeouts 0,0,1219,0,0,972 last cancelled message type 30 dest 127

=== Network ===

Slowest loop: 52.60ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8- WiFi -

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.25

WiFi MAC address f0:08:d1:02:a1:0b

WiFi Vcc 3.34, reset reason Power up

WiFi flash size 2097152, free heap 26896

WiFi IP address 192.168.0.19

WiFi signal strength -58dBm, mode 802.11n, reconnections 0, sleep mode modem

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0

M98

Error: M98: No P or R parameter; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Valkyrie 3030 V001" ; set printer name

M669 K1 ; core xy; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.0 S1 ; physical drive 0 goes forwardsM569 P0.1 S1

M569 P0.1 S1 ; physical drive 1 goes forwardsM569 P0.1 S1

M569 P0.2 S1 ; physical drive 2 goes forwards

M569 P0.3 S1 ; physical drive 3 goes forwards (spare)

M569 P0.4 S1 D3 V30 ; physical drive 4 goes forwards D3=stealthchop

M569 P0.5 S0 D3 V30 ; physical drive 5 goes backwards

M569 P0.6 S1 D3 V30 ; physical drive 6 goes forwardsM584 X1 Y0 E2 Z0.4:0.5:0.6 ; set drive mapping FL,FR,RC

M350 X16 Y16 I1 ; configure microstepping with interpolation

M350 Z16 E16 I1

M92 X80.00 Y80.00 Z320.00 E260.00 ; set steps per m

M566 X500.00 Y500.00 Z800.00 E100.00 P1 ; set maximum instantaneous speed changes (mm/min)

M203 X8000.00 Y8000.00 Z1000.00 E400.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z200.00 E250.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1400 I10 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima "Travel Area"

M208 X270 Y240 Z405 S0 ; set axis maxima "Travel area"; Endstops

M574 X1 S1 P"!io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in

M574 Y2 S1 P"!io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in

;M574 Z2 S2 P"!io4.in" ; != invert signal

M574 Z2 S4 ; configure sensorless endstop for high end on Z, 1 = low end, 2 = high end. S4 multipule motors

M671 X-34.4:296:132.5 Y0:0:296 S25 ; leadscrews at front left,front right, rear Center s= max correction factor must be in same order as M584; Sensorless config

M915 P0.4:0.5:0.6 S5 R0 F0 H200 ; Lower values less sensitive S3, F filter, R =Action; Z-Probe

M558 P8 C"!io3.in" H5 F600 T18000 A30 S0.03 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 Z0.5 ; set Z probe trigger value, offset and trigger height bigger the posative number the closer to the bed

G31 P500 X26 Y6 ; set x,y trigger value, offset and trigger height

M557 X30:270 Y10:250 S40 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed T°C" ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"out0" T0 Q10 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 R0.140 K0.103:0.000 D43.19 E1.35 S0.90 B0 ; PDI info for 8mm aluminium bed 700w Heater NTC 100K 3950

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4267 A"Extruder T°C" ; configure sensor 1 as thermistor on pin e0temp (104gt2)

M950 H1 C"out1" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R3.548 K0.733:0.000 D4.96 E1.35 S1.00 B0 V23.9 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out3" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

M98 P/macros/3zhome - WiFi -

-

@moth4017 said in DWC Duet Web Control 3.4.0-rc2 no extrude or retract:

M98

Error: M98: No P or R parameterThe command to send is

M98 P"config.g"@moth4017 said in DWC Duet Web Control 3.4.0-rc2 no extrude or retract:

Duet 3 Mini 5+ version 3.4.0rc1

Can you please test with RC2?

https://github.com/Duet3D/RepRapFirmware/releases/download/3.4.0rc2/DuetWebControl-SD.zip

https://github.com/Duet3D/RepRapFirmware/releases/download/3.4.0rc2/Duet3Firmware_Mini5plus.uf2

https://github.com/Duet3D/RepRapFirmware/releases/download/3.3/DuetWiFiServer.bin

-

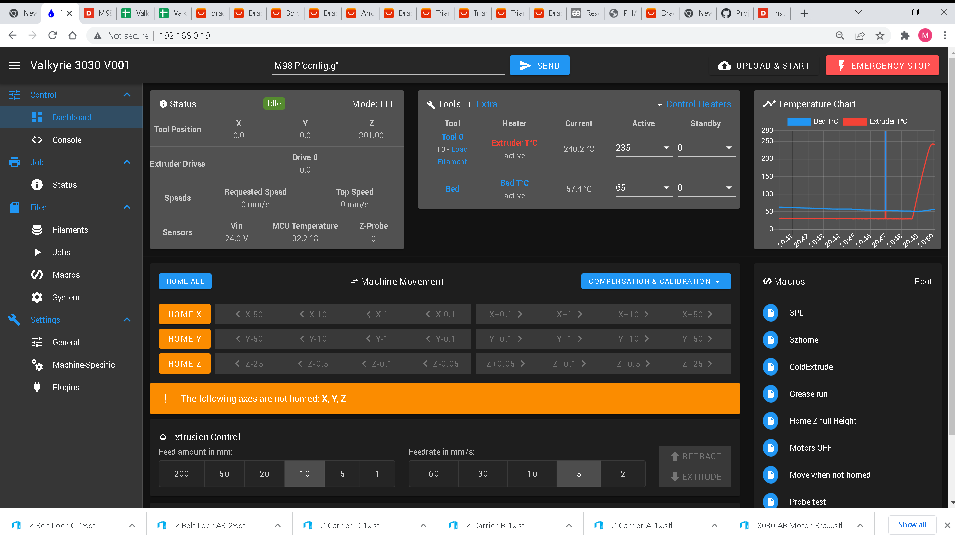

@phaedrux

Hi had issues updating firmware via DWC

Error: M997: In-application programming binary "0:/firmware/Duet3_SDiap32_Mini5plus.bin" not foundso did the update via usb.

M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabledUpdated to rc2

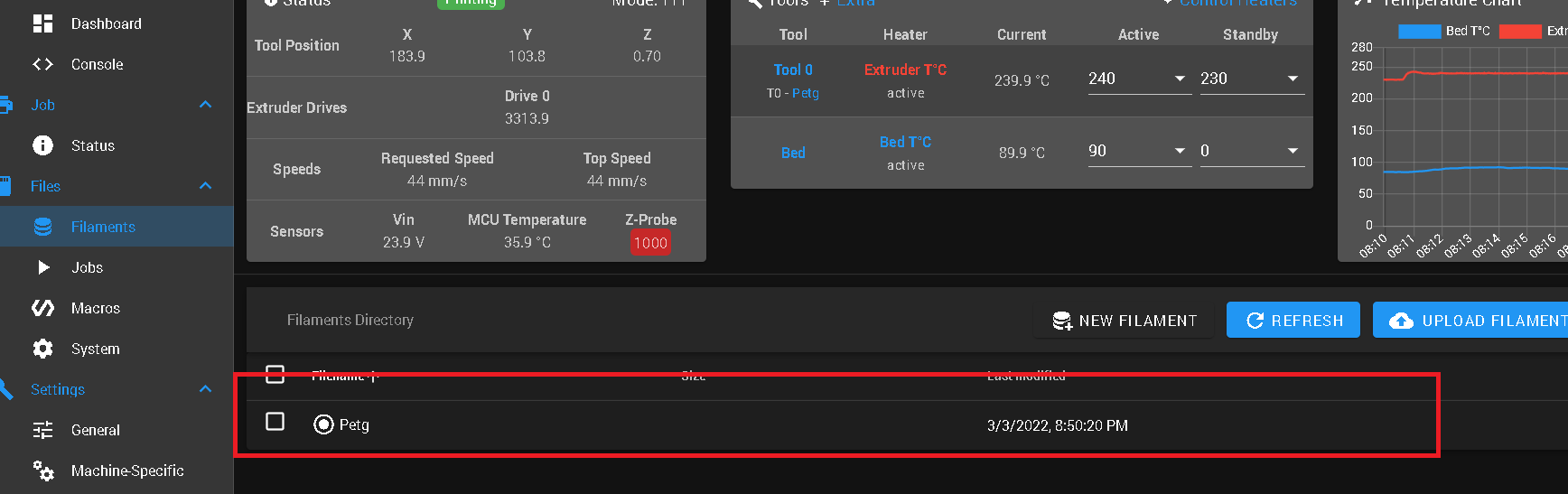

I worked out the issue i did not have any filaments loaded, didn't realise i had to enter a filament , im still not sure why it needs filaments in DWC as all the info comes from the slicer

-

@moth4017 said in DWC Duet Web Control 3.4.0-rc2 no extrude or retract:

Error: M997: In-application programming binary "0:/firmware/Duet3_SDiap32_Mini5plus.bin" not found

You appear to be missing this file.

https://github.com/Duet3D/RepRapFirmware/releases/download/3.3/Duet3_SDiap32_Mini5plus.bin

You should place it in the firmware directory to make future updates possible.

I can't really make out the details in your screen shot. What do you mean by loading a filament?

-

-

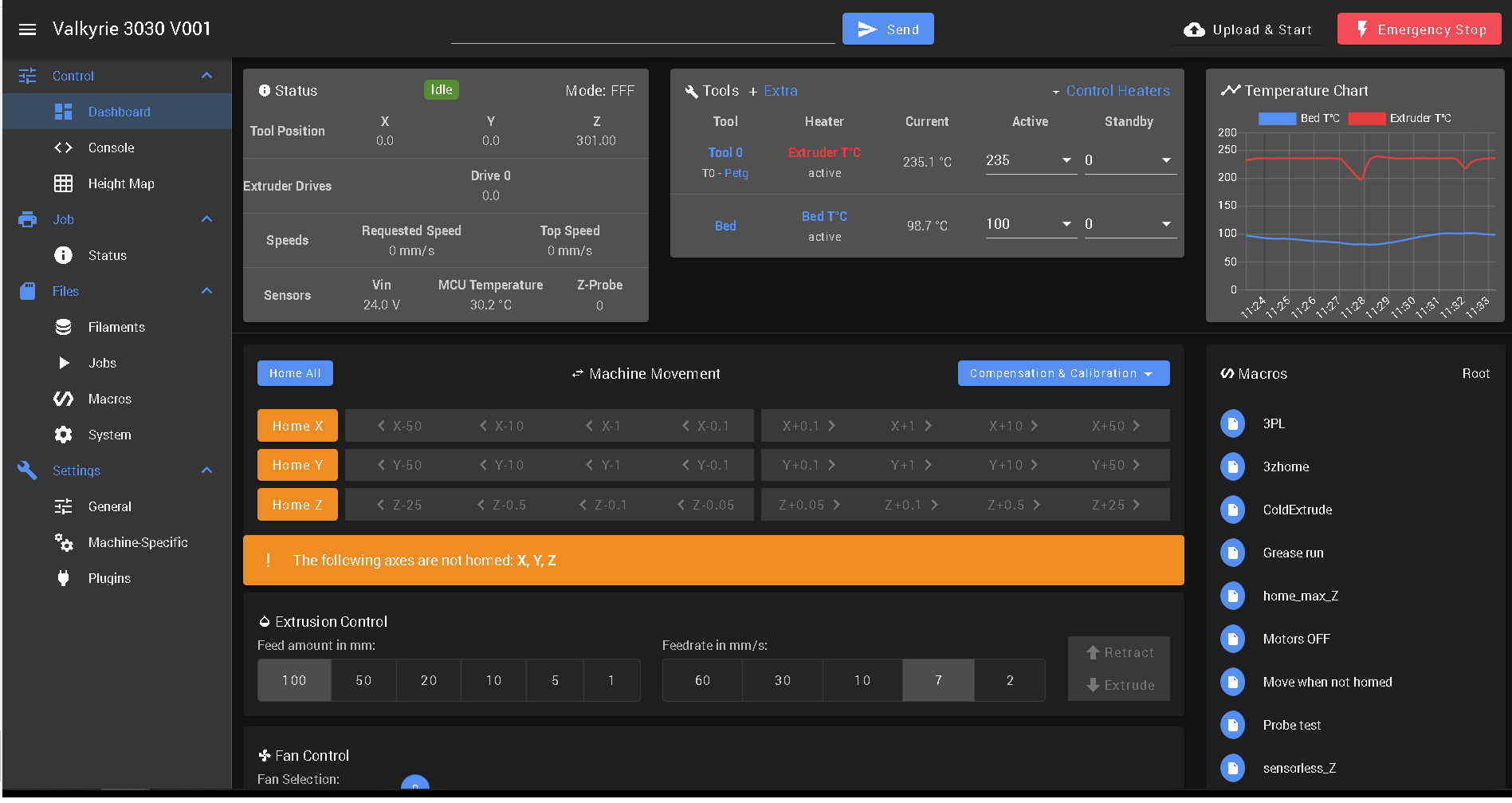

since the new release of 3.4.0 i have this issue again where the retract and extrude is grayed out

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Valkyrie 3030 V001" ; set printer name M669 K1 ; core xy ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0 goes forwardsM569 P0.1 S1 M569 P0.1 S1 ; physical drive 1 goes forwardsM569 P0.1 S1 M569 P0.2 S1 ; physical drive 2 goes forwards ( blown needs replacing) M569 P0.3 S1 ; physical drive 3 goes forwards (extruder M569 P0.4 S1 D3 V30 ; physical drive 4 goes forwards D3=stealthchop M569 P0.5 S0 D3 V30 ; physical drive 5 goes backwards M569 P0.6 S1 D3 V30 ; physical drive 6 goes forwards M584 X1 Y0 E3 Z0.4:0.5:0.6 ; set drive mapping FL,FR,RC M350 X16 Y16 I1 ; configure microstepping with interpolation M350 Z16 E16 I1 M92 X80.00 Y80.00 Z320.00 E260.00 ; set steps per m M566 X500.00 Y500.00 Z800.00 E100.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X8000.00 Y8000.00 Z1000.00 E400.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z200.00 E250.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E1400 I10 ; set motor currents (mA) and motor idle factor in per cent M84 S20 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima "Travel Area" M208 X270 Y240 Z405 S0 ; set axis maxima "Travel area" ; Endstops M574 X1 S1 P"!io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in M574 Y2 S1 P"!io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in ;M574 Z2 S2 P"!io4.in" ; != invert signal M574 Z2 S4 ; configure sensorless endstop for high end on Z, 1 = low end, 2 = high end. S4 multipule motors M671 X-34.4:296:132.5 Y0:0:296 S25 ; leadscrews at front left,front right, rear Center s= max correction factor must be in same order as M584 M558 P8 C"!io3.in" H5 F600 T18000 A30 S0.03 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 Z0.9 ; set Z probe trigger value, offset and trigger height bigger the posative number the closer to the bed G31 P500 X26 Y6 ; set x,y trigger value, offset and trigger height M557 X30:270 Y10:250 S40 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed T°C" ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"out0" T0 Q10 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 R0.140 K0.103:0.000 D43.19 E1.35 S0.90 B0 ; PDI info for 8mm aluminium bed 700w Heater NTC 100K 3950 M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4267 A"Extruder T°C" ; configure sensor 1 as thermistor on pin e0temp (104gt2) M950 H1 C"out1" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 R3.435 K0.348:0.274 D6.64 E1.35 S1.00 B0 V23.9 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out4" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out3" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 T0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M98 P"/macros/3zhome" -

@moth4017 Where do you select T0? I have a T0 at the bottom of config.g to make sure it's selected.

-

@stephen6309 when i checked in the console which tool i have it has defaulted to T0 , but i have added it now to my config.g now.

Thanks for the reply -

Ok even though the firmware new that the tool T0 was selected adding T0 to the config seems to have fixed this issue.

-

This post is deleted! -

@arnold_r_clark

Ill get some Rat poison

-

same here with 3.4

Found out that you have to select tool active , then it works