MFM recurring error

-

@wouldstain Let's look further. In my setup, the filament can go into the MFM with an angle - if it was too much bent, I got false readings, especially with stiff filaments. If you can exclude mechanical problems, you might want to check print moves at a higher distance (currently, you stick with the recommended 3 mm). Try 5-10 mm instead.

Finally, there is a hot debate about the usefulness of adding a capacitor to the power lines of the MFM, you can look it up here. But I think this will only help in case of unstable supply voltage.

One last question: where do you locate your MFM, and how fix is the distance between it and the extruder?

-

@alankilian gapped with some paper as suggested.

Same issue:

m591 d0

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 25.63mm/rev, allow 1% to 200%, check printing moves every 3.0mm, version 3, mag 131 agc 74, measured sensitivity 33.09mm/rev, min 1% max 132% over 61.4mm -

Bummer!!!

As an experiment and even though it's wasteful, maybe helpful.

Try:

- Raising the extruder temp a LOT. 15C or so.

- Moving the extruder 20mm away from the bed.

- Run your print.

You'll be making spaghetti, but this will demonstrate if the extruder is clogging or if there's some interaction between the extruder and the print that's jamming the filament.

If it "prints" without an under-length move we'll figure out more experiments.

-

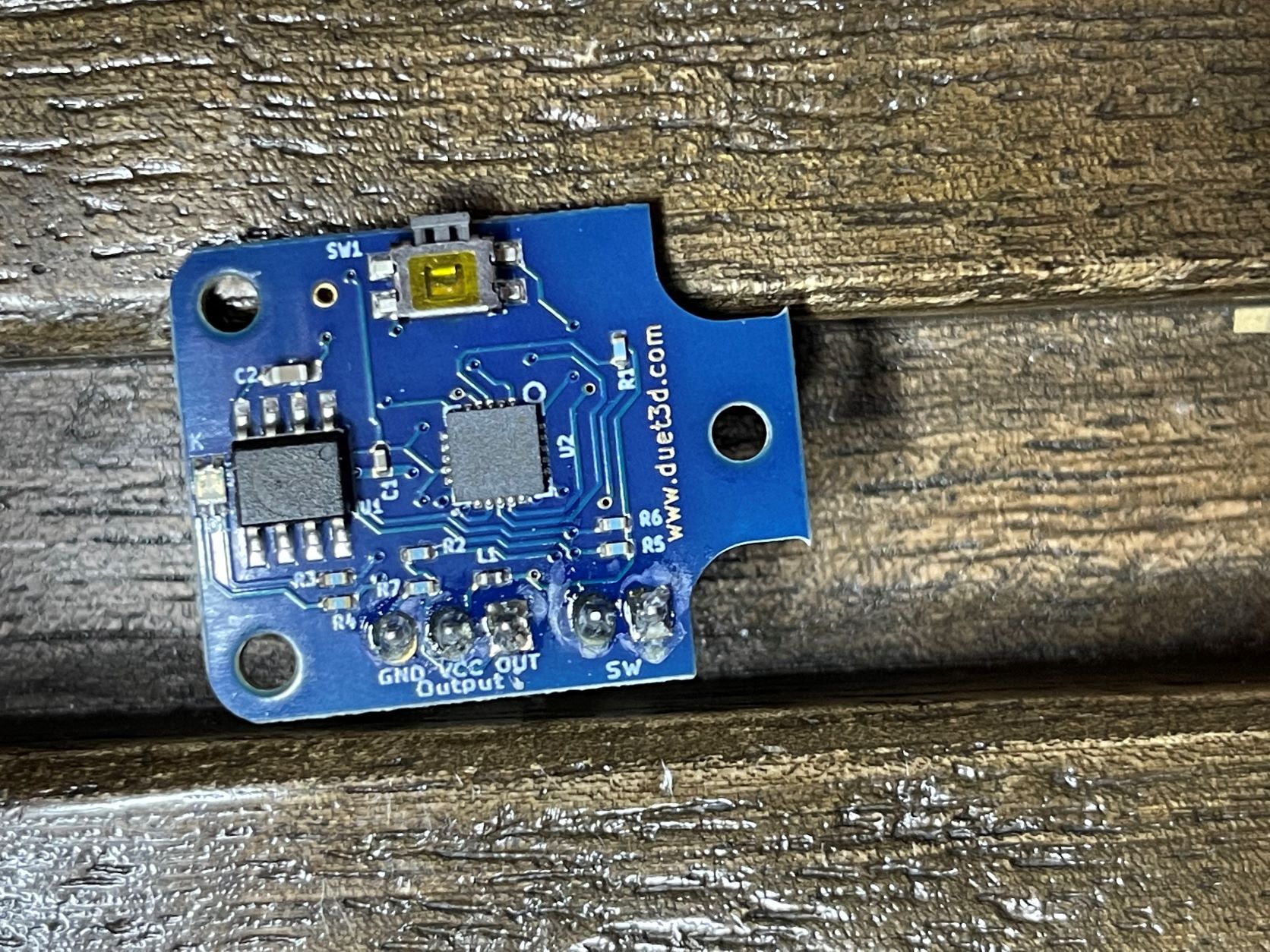

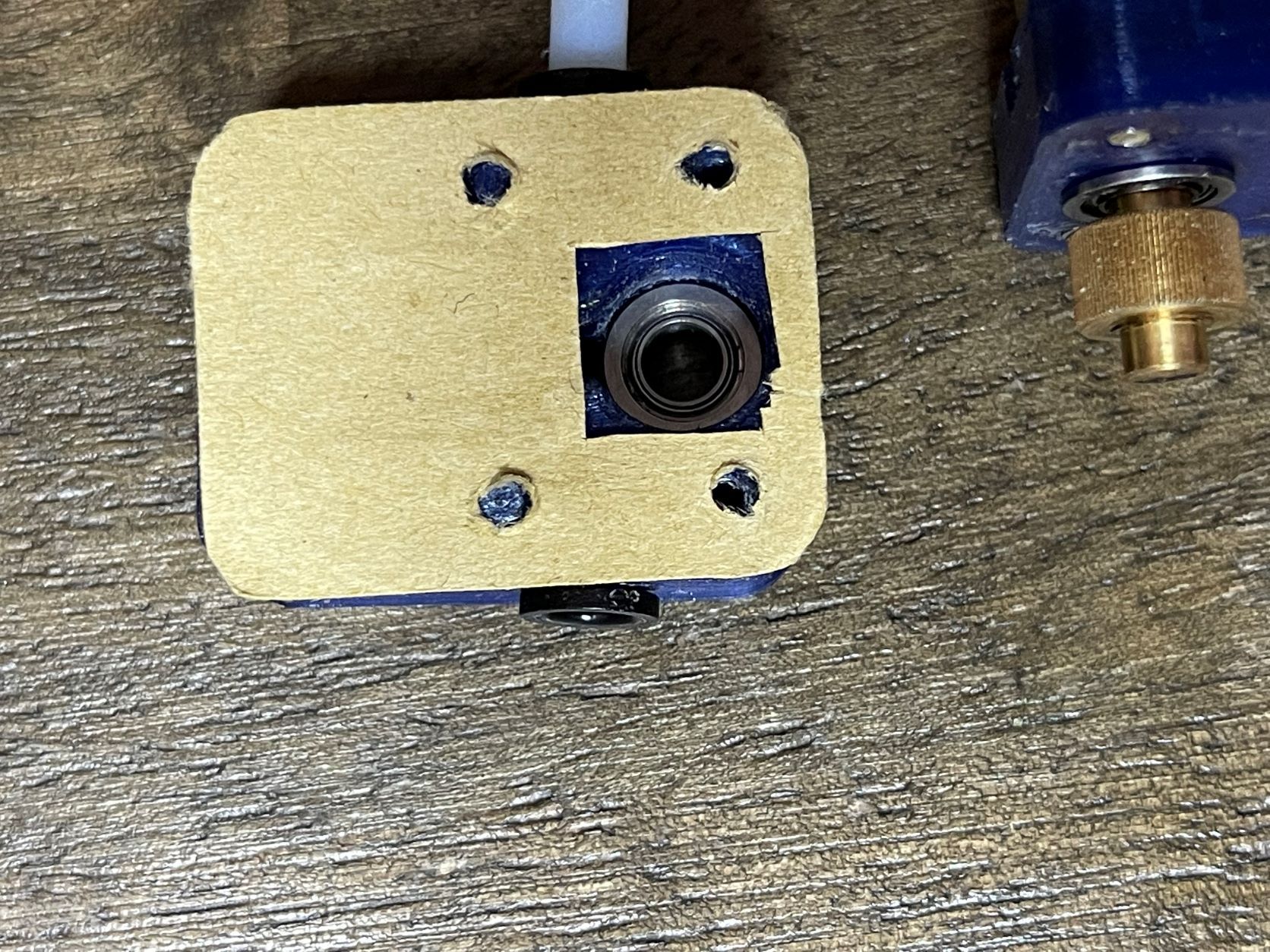

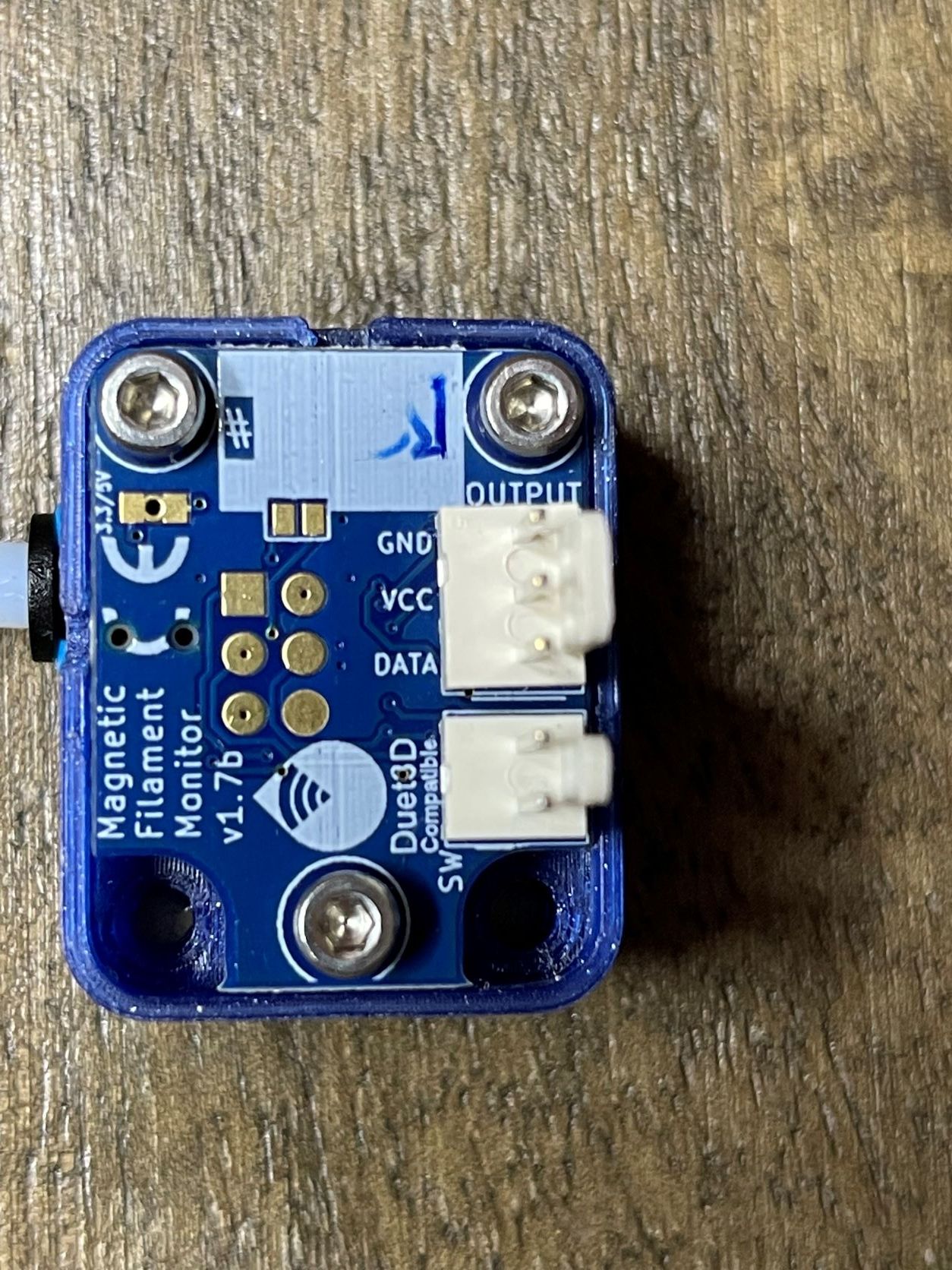

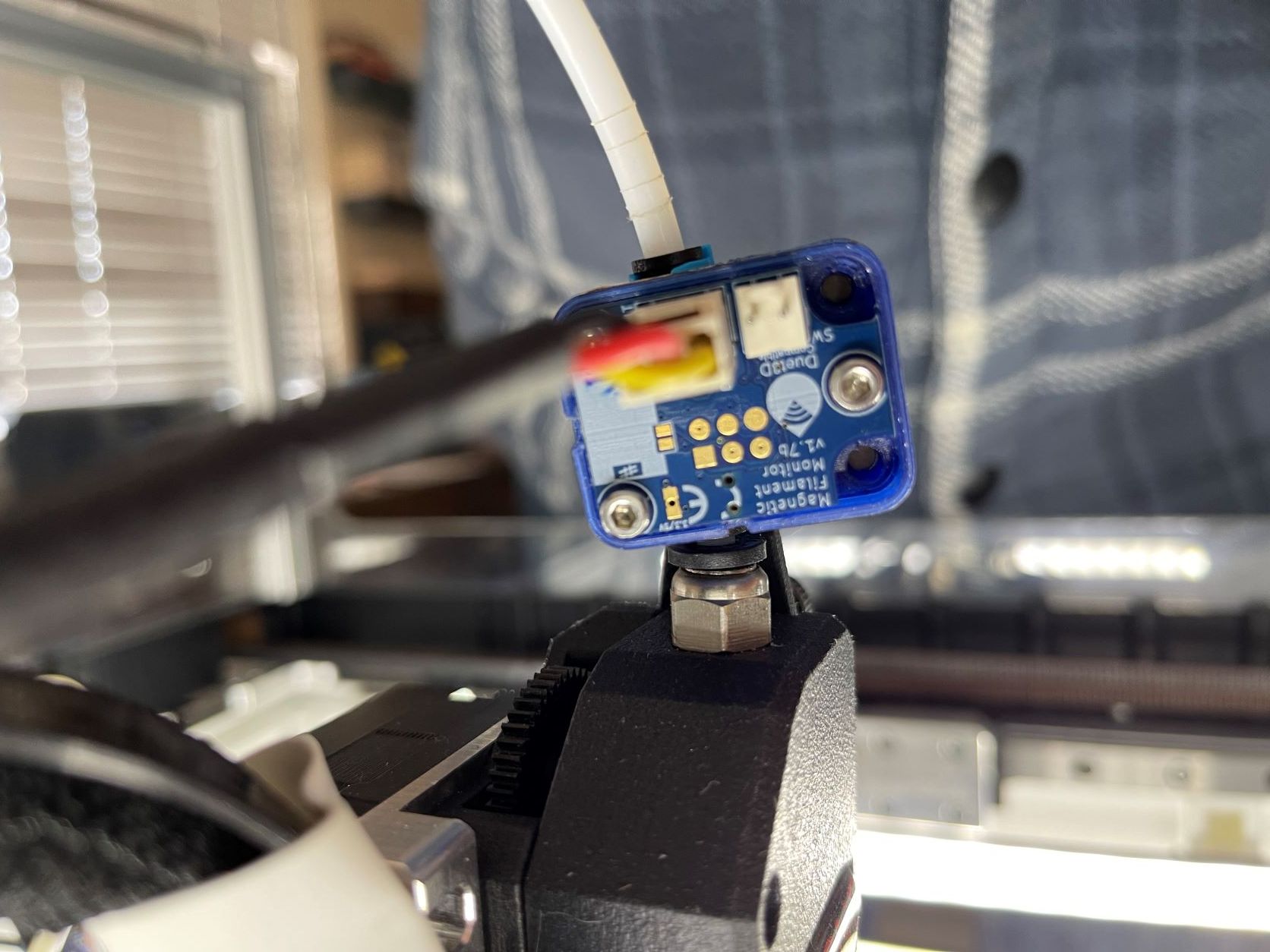

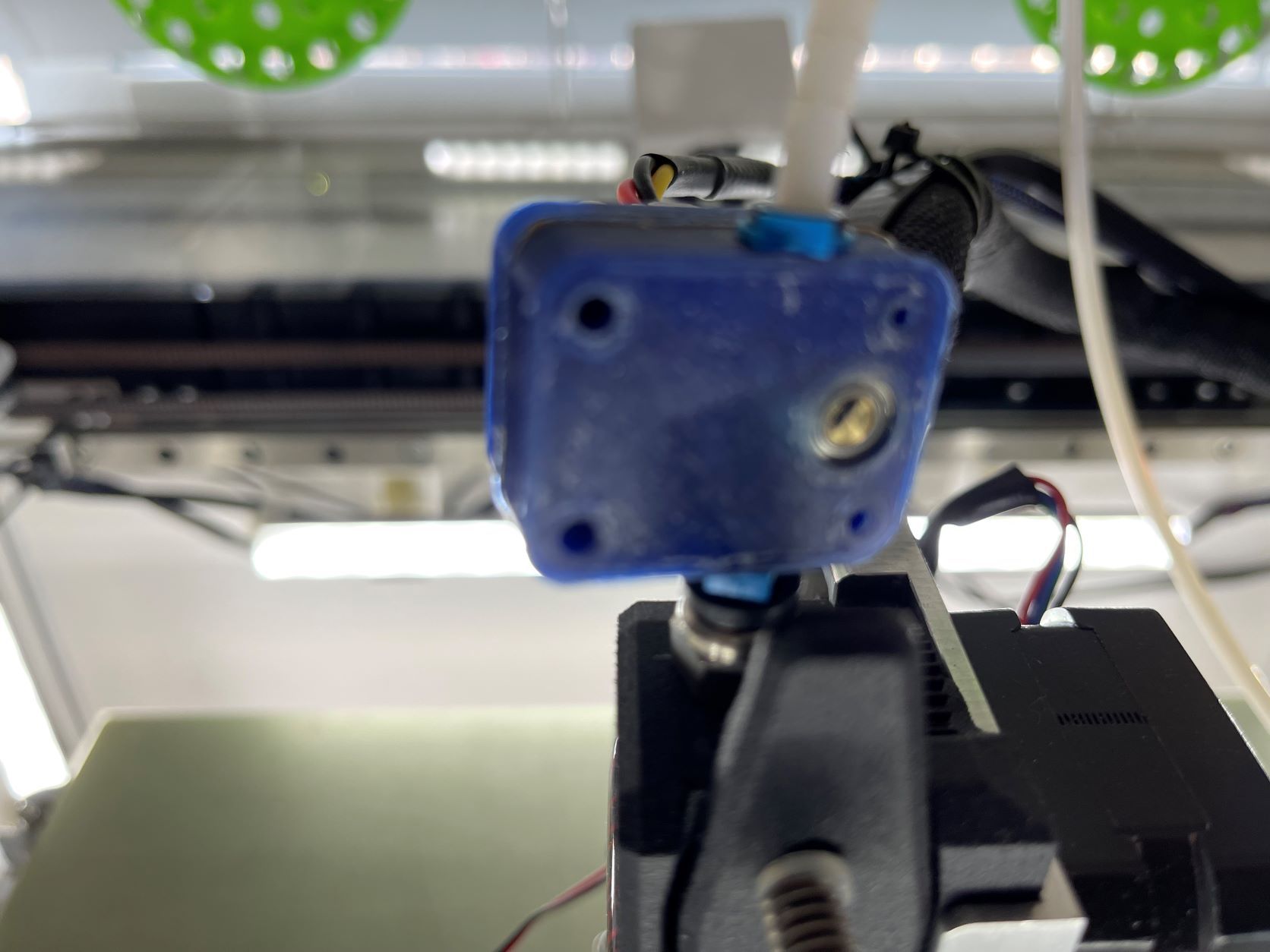

Photos of your sensor setup and printer? Maybe we can spot something.

-

@alankilian I can tell you for certain the extruder is not clogging.

I've actually set up a macro to disable the MFM when printing PLA:M591 d0 s0This allows me to run entire PLA jobs without interruption but also without the protection of run-out detection. I was able to finish off the tail ends of two spools yesterday thanks to having the MFM enabled but there were several false-stops during the process.

-

@phaedrux As soon as the current job is complete I'll get some photos.

Assuming you want to see it mounted as well as on the bench and disassembled. -

-

Have you tried re-printing the casing in higher quality?

-

@phaedrux I havent but I can although the casing is clean on the inside. I had some first layer issues IIRC and it still has some dry bedweld on it (got distracted and forgot to rinse).

-

@infiniteloop I have the MFM sitting directly atop the extruder and the PTFE tube comes in close to vertical so I'm not concerned about the angle of the filament path.

I am considering picking up a piece of copper tube from McMaster and replacing the bit of PTFE tubing connecting the MFM to the extruder but I really dont think that's where the problem is.

I'm inclined to print a new casing and giving that a try as I noticed that the ring on the MFM sensor from the magnet rubbing was a partial circle which would indicate to me that there's a slight tilt to the magnet.

I think an injection molded case would remove any uncertainty around it but I'm not certain that would resolve this issue.

-

@wouldstain said in MFM recurring error:

I think an injection molded case would remove any uncertainty around it but I'm not certain that would resolve this issue.

My MFM works reliably, the electronics are pretty well engineered. The - self-printed - case needed heavy postprocessing, I had to file, drill, cut and sand a lot. Especially the filament path and the idler are problematic, the often mentioned distance between magnet and sensor is no theme anymore since introduction of the 2 mm magnet in v2. So yes, an injection molded case would be helpful.

Given the high precision of detected filament movement, a direct coupling with the extruder - or better, an integrated design - is still on my wish list …

But, again: if the magnet rotates as intended, PCB and I2C transmission work flawlessly. @dc42 has made a remarkable job to ensure reliability of the data, so, as long as we get our cables right, we won't run into problems on this side. Simply put: it's the mechanics we have to take care of.

-

@infiniteloop No doubt! I'm still pretty new at this and I generally assume it's something I'm doing. Given what you're saying about post processing and my questionable print quality, I would not be surprised if there are tolerance issues with my casing.

-

@phaedrux

Finally got around to reprinting case. Used PLA this time instead of PETG.

It's alot cleaner on the outside but really no difference on the inside.

I ran a needle file through the feed path just to be certain there's no blobs or burrsInitial reading (before printing first time). As you can see, AGC has gone up quite a bit.

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 28.80mm/rev, allow 60% to 160%, check printing moves every 3.0mm, version 3, mag 133 agc 111, no calibration data

1st test / calibration print on 20mm calibration cube:

35% ona "too little movement error":

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 28.80mm/rev, allow 60% to 160%, check printing moves every 3.0mm, version 3, mag 132 agc 109, measured sensitivity 25.84mm/rev, min 35% max 106% over 983.4mm

adjusted M591 while paused to:

M591 P3 C"e0_stop" S1 D0 L25.84 R35:130Print completed without further error.

2nd test completed without error.

3rd test printed 2 x 20mm calibration cubes simultaneously

Stopped at 88% with the following:

M591 d0

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 25.84mm/rev, allow 35% to 130%, check printing moves every 3.0mm, version 3, mag 132 agc 109, measured sensitivity 26.05mm/rev, min 0% max 109% over 2811.8mmSo... Even with the new case, it's still randomly stopping.

I'm thinking there's a problem with the MFM.

-

Please send an email to warranty@duet3d.com and CC your reseller. Include a link to this forum thread and the details of your original purchase. You'll receive a reply with a form to fill out.

-

@phaedrux done. thank you!