Toolboard Heater Tuning and Fan Error

-

can you move the extruder connection to the expansion board?

-

@Veti i think that message was generated by the interpolation settings.

I changed yesterday only the following line:

M350 X16 Y16 Z16 E16 I1to

M350 X16 Y16 Z16 I1 M350 E16 I0after that change, the message was gone.

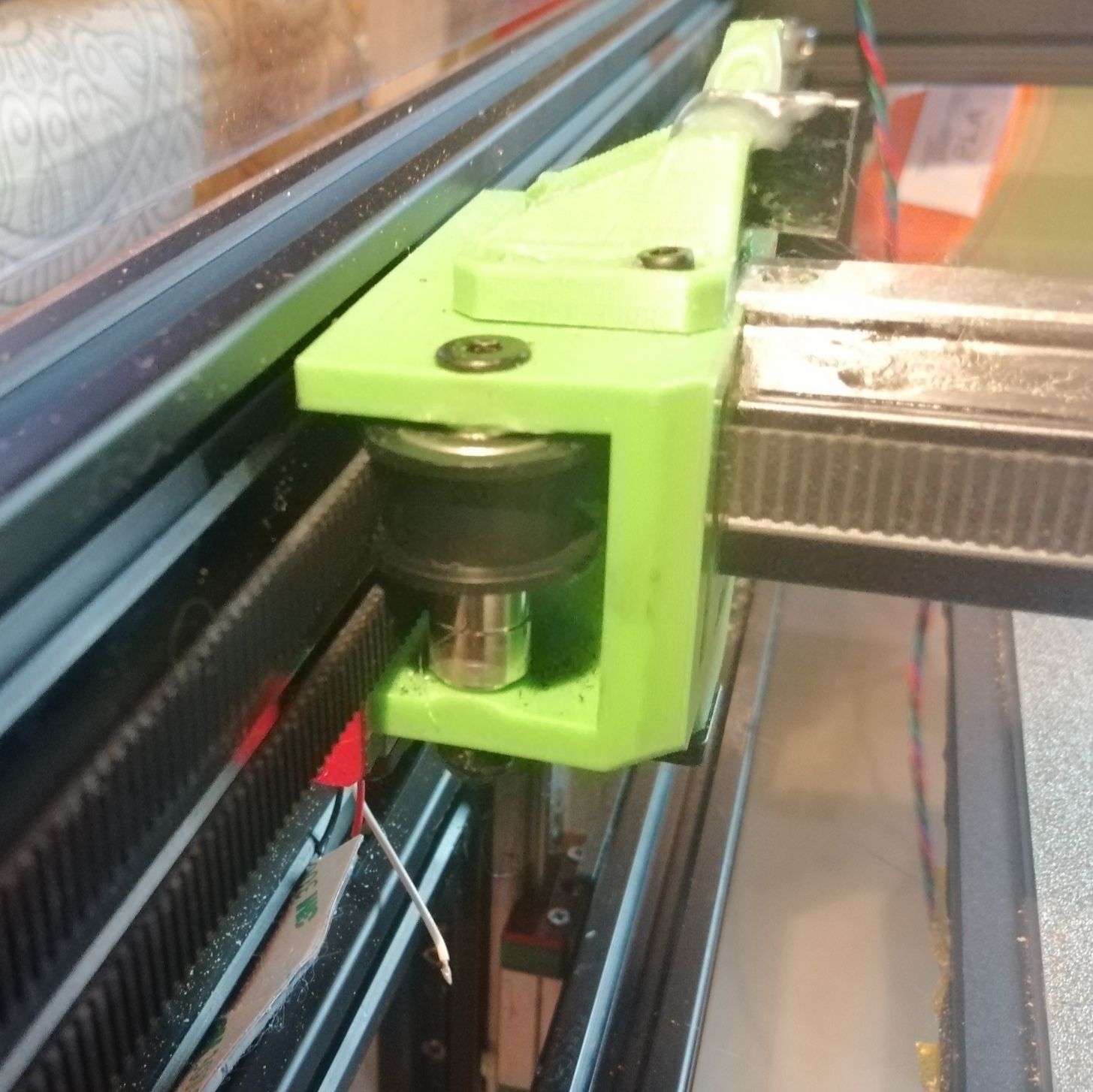

i could try it as a test, but I don't have printed the motor mount for the direct drive setup

-

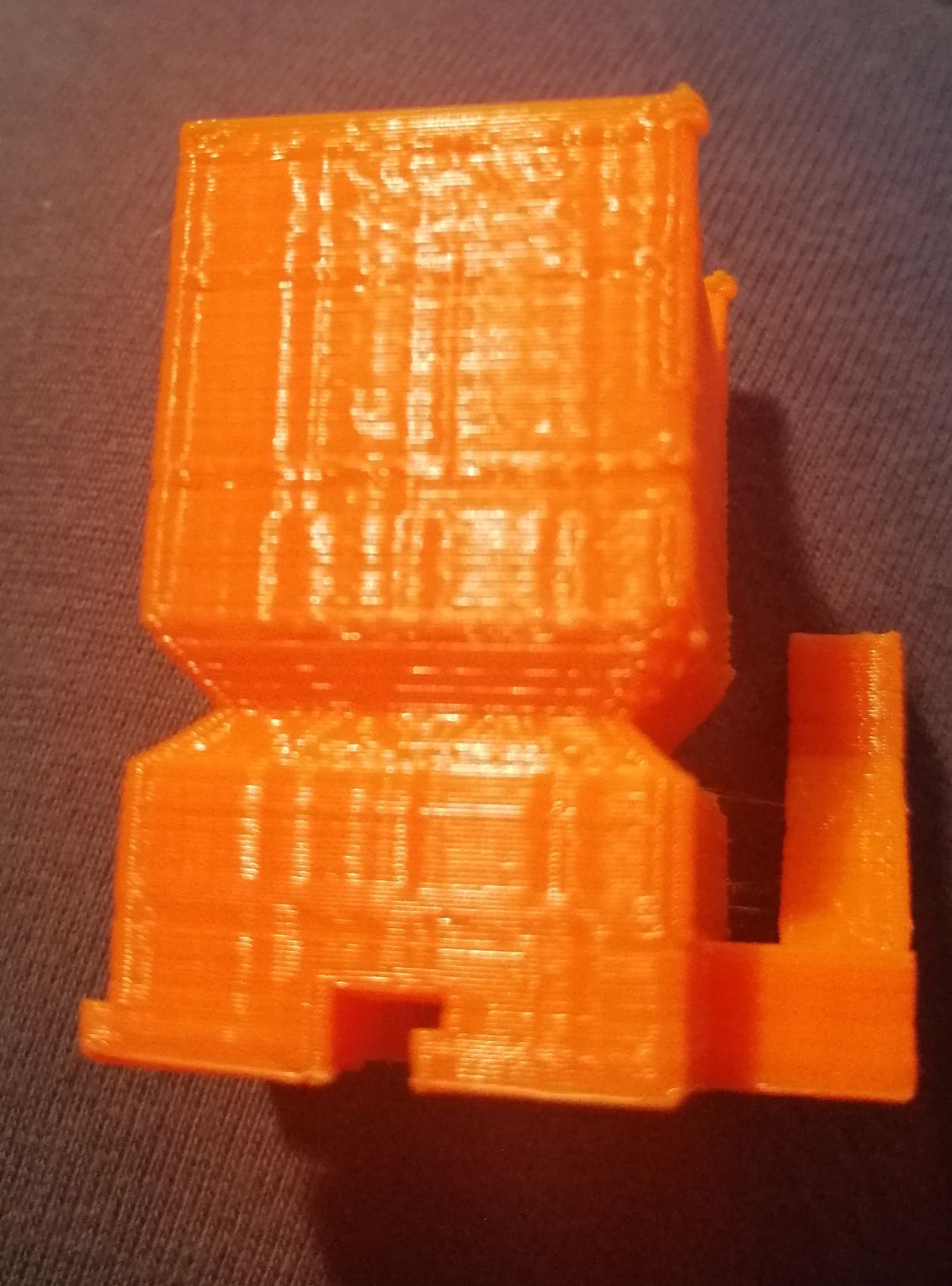

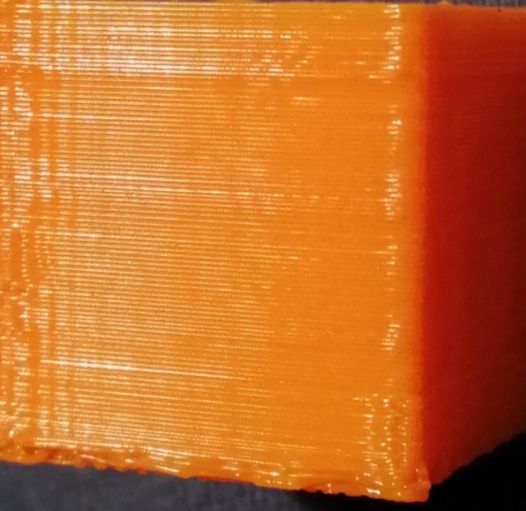

I printed a test cube to see if now everything is work g as it should,

This is my second or third print with petg.

What could cause these stripes?

Max instantaneous speed change x+y=1000

Max acceleration x+y=750

I played a little bit with the settings, but I think it isn't speed related? Perhaps some small mechanical problems? But I can't find them

-

could be belt on smooth pulley

damaged bearing

1.8 stepper artefacthard to tell

-

@Veti right now I have only 0.9 degree steppers on the machine. I have 2 flat pullys on the teethed belt side. But the kit was shipped like that

Do you think that is the problem ?

I checked the bearings. They are all good. The Machine has printed perhaps 15 hours after I finished the build

Could be the belt tension also play a role?

What do you think is a good starting point?Ive read somewhere that ok a CoreXY it should sound a little bit like a low guitar string. Around 60-80 hz?

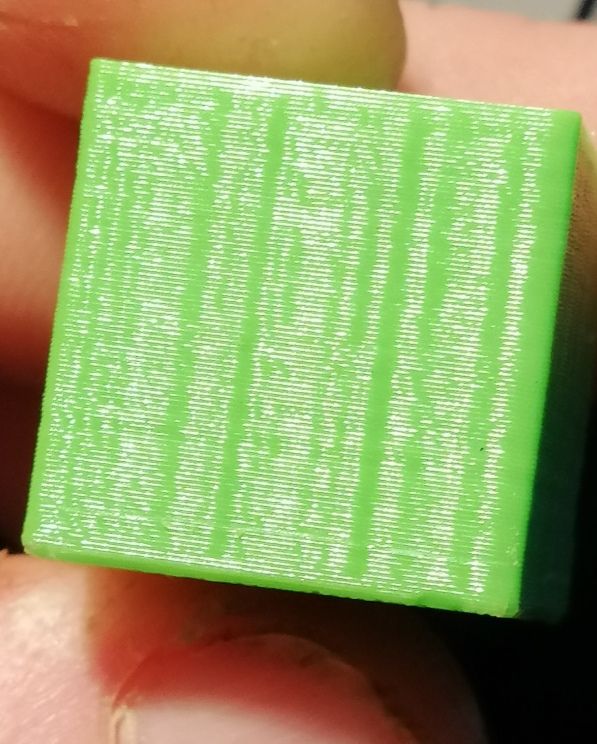

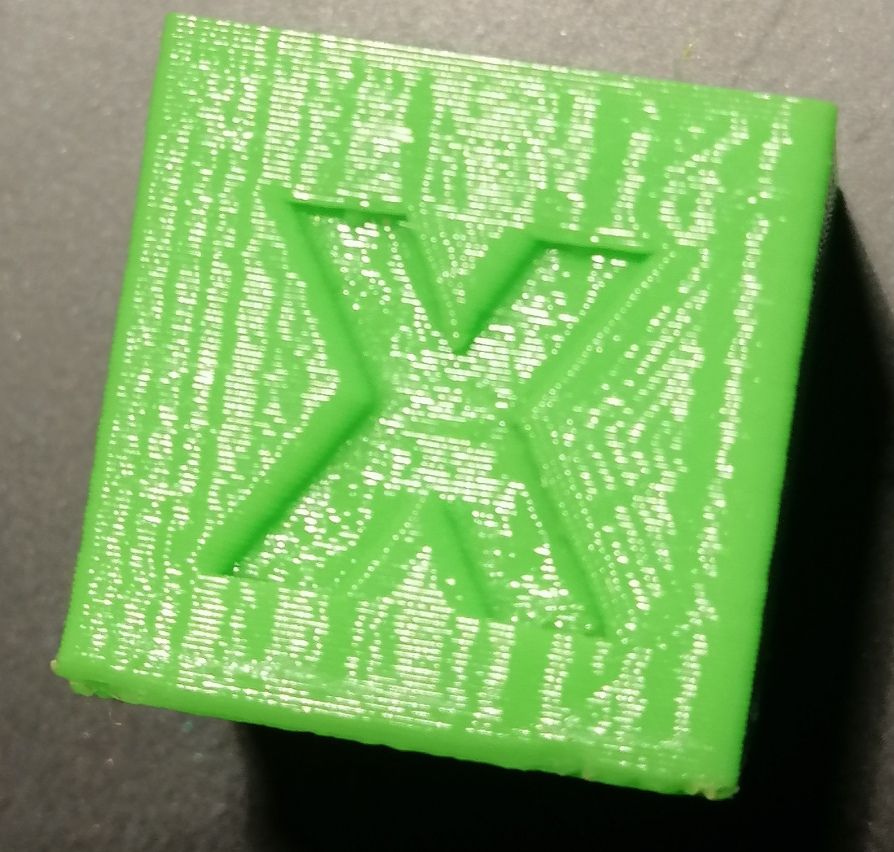

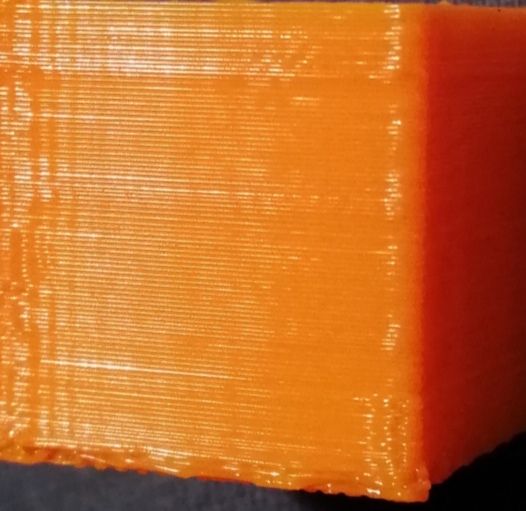

I tested now with pla and the same speed settings, but switched from cura 4.8 to prusa slicer.

It looks a lot better. Perhaps the slicer profile has wrong settings or other config issue

-

try changing the belt tension and see if that changes the pattern

-

-

@Veti

Now with the same speed settings, just sliced in prusa slicer. The other was cura 4.8Perhaps its a wrong slicer setting

I didn't change other parameters.

Could it be the infill that causes this thin lines? It had 20% infill, th spaces between the lines are matching the infill lines really close

-

yes it could be infill causing the pattern.

-

@Veti it was the infill ! / slicer settings. 2 additional Wall Perimeters solved the issue