Slicer speed: S3d is faster then ideaMaker?

-

@BlueDust said in Slicer speed: S3d is faster then ideaMaker?:

I am trying to learn how to use ideaMaker, and the first print, I found took over 9 hours. Same print in S3d took ~5.5 hours. Settings were not exactly the same, but still...

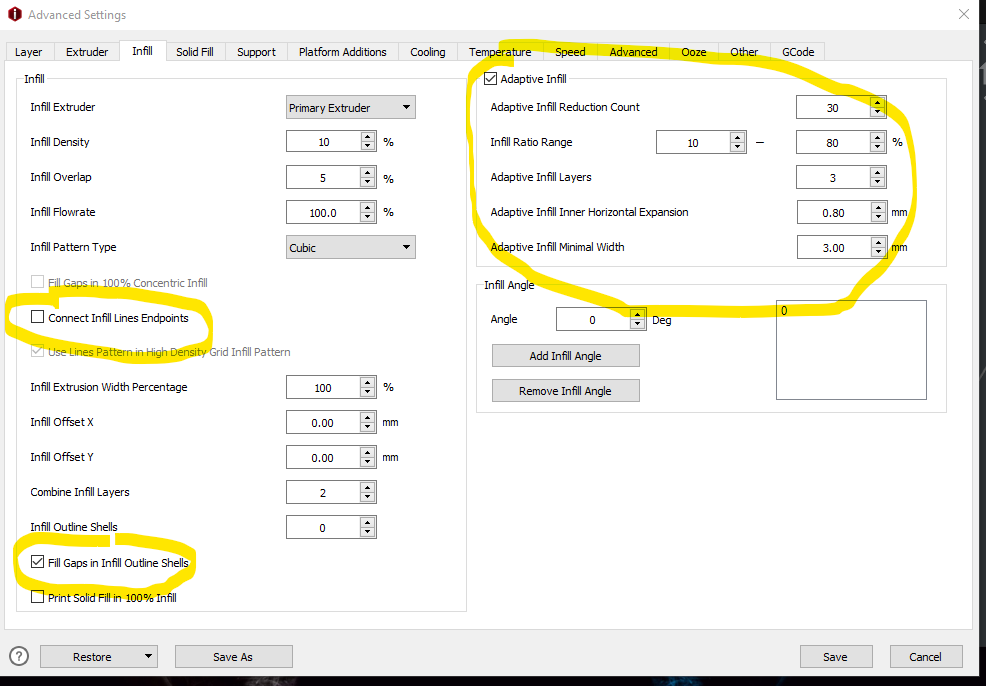

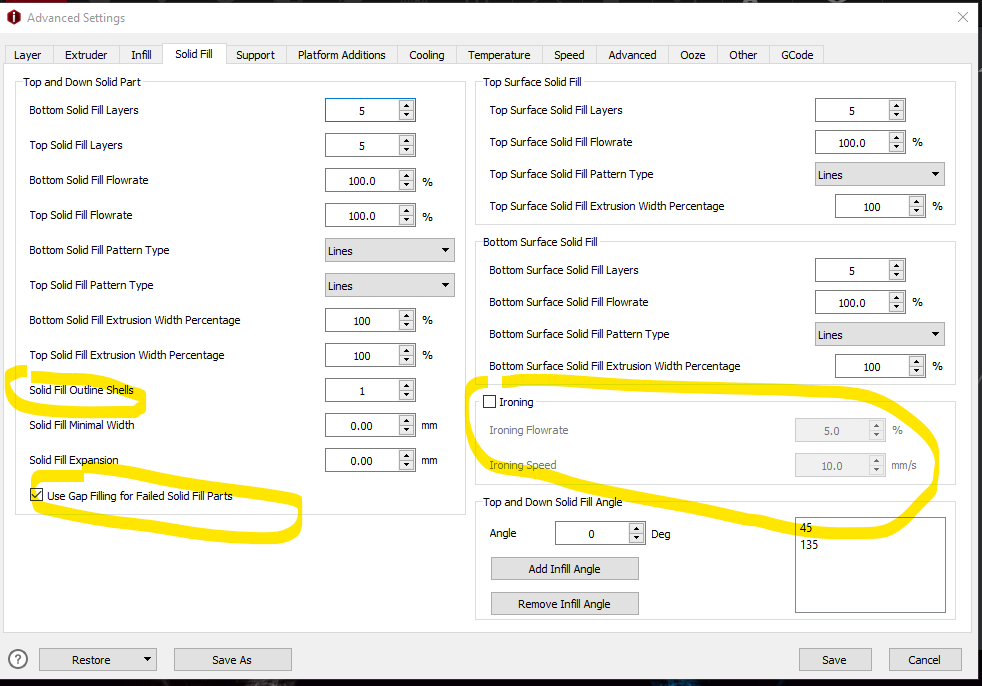

IM defines speeds for lot more features than S3D so you need to match them all ... the g-code and speed is more less same between then IMHO. Now there are options in IM like adaptive infill that will increase speed significantly on some parts (but slicing will take much longer). There's lot more features to tweak so it will take a while till you get it all.

Compare the g-code preview. Often with "seamingly same" settings the IM will actually generate 2 more perimeters than S3D making object print significantly slower.

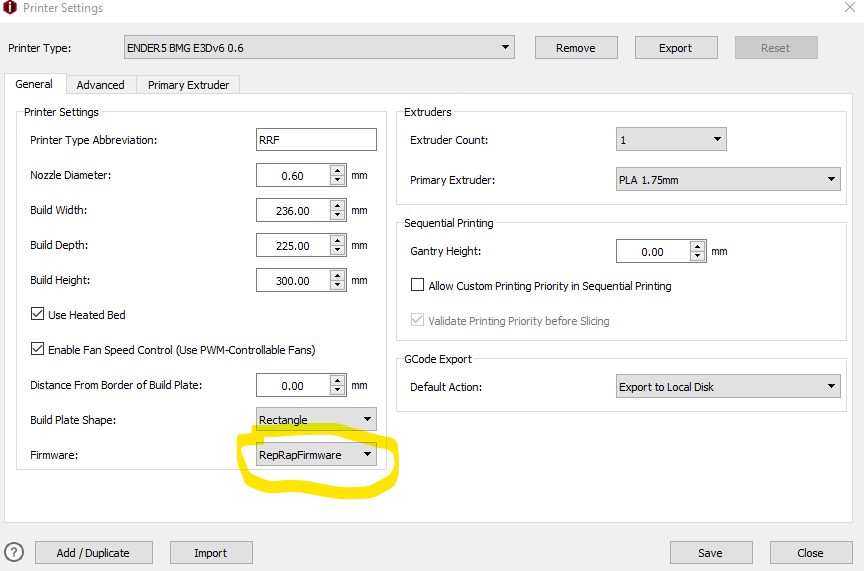

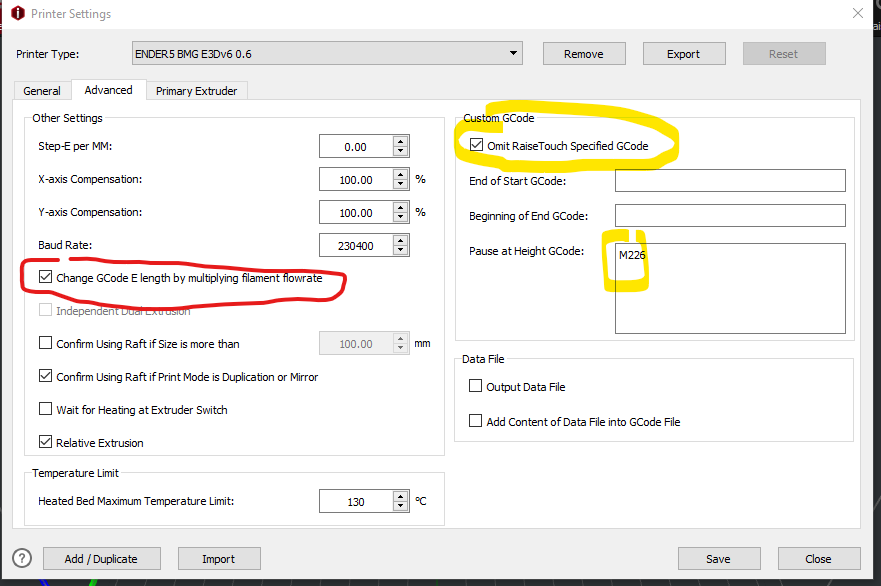

My first question is around ideaMaker gcode files, and why I wasn't able to increase the speed using options on the Duet2. Even at 300% or 20% speed, didn't affect the print at all. Duet also couldn't tell what layer was currently being printed. I already set ideaMaker to RepRap, and now wondering if I should change it to Marlen to see if that helps any but don't know why it would.

Few things are important wrt this.

printer settings

here, the "change gcode e lenght.... is super important, if that is not checked IM will try to setup flow rate by using G-code to manipulate % and not by actually changing E values, this also interfere with how speed % later on work so you really want this checked

second, add this to your start g-code in IM and the layer detection will work:

; layer_height={layer_height} ; Layer height={layer_height} ; layerHeight,{layer_height} ; layer_thickness_mm={layer_height} ; layerThickness={layer_height} ; ... from here continue with your normal start codeRRF uses this info from the g-code to detect layer height, since IM normally do not add this comment to g-code RRF has no clue about the layer height, this way you add the info

I tried printing a test cube, and it just make a single square then large blobs that kept jamming the nozzle. Filament sensor kept stopping print. "Appeared" it just wouldn't go to the 2nd layer but couldn't tell as printer kept stopping.

dunno about filament sensor issue, I don't have that problem, what is your filament sensor configuration?

I myself have this in "Layer change gcode"

M98 P"filamentsensor.g"and in filamentsensor.g on the duet I have

M591 D0 P7 C"^e0stop" L0.124 R50:5000 E3 S1 A1so I reset the filament sensor configuration for every layer

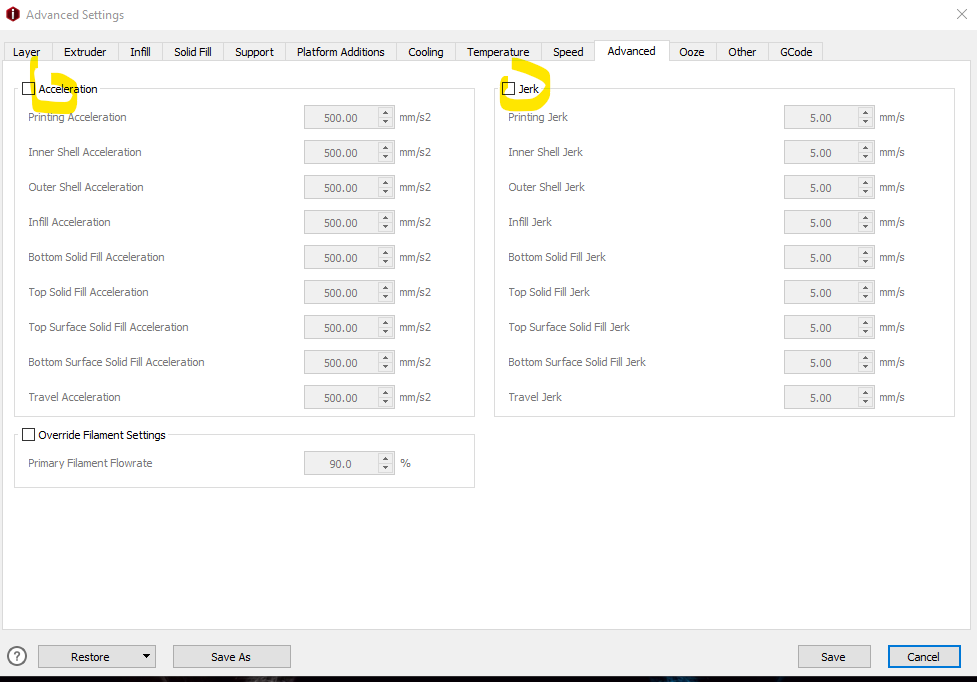

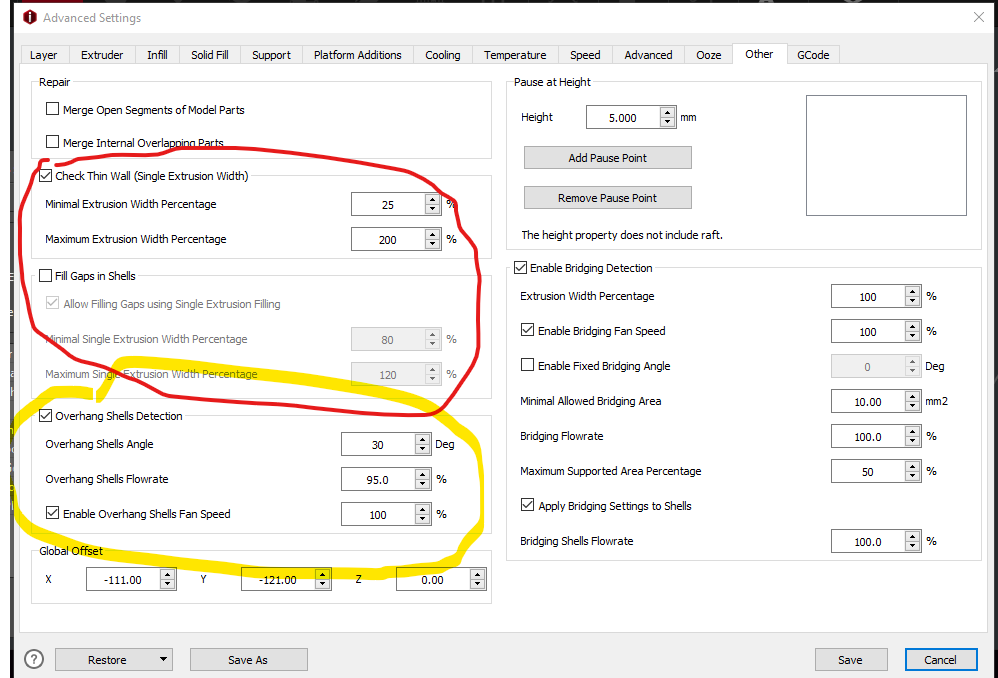

Some huge speed modifiers:

-

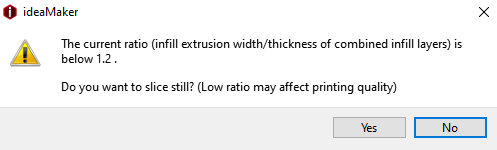

That is awesome! I am still trying to go through this and understand the settings, and review the preview, but now I am getting an error.

I have fixed this before in S3d, but it's been awhile, and not sure what to do in iM.

I did change the extrusion width from .40 to .48 and that didn't fix it.Thanks for the help!

-

@BlueDust

I found it. Infil was printing layer twice as thick to save time... -

that happens when you use "combine layers" for infill or support to print more then one layer at a time for them... I usually do this as for e.g. with 0.6mm nozzle I can easily print 0.1mm layer height for the perimeter and 0.5mm layer for the infill so I set layer height to 0.1mm and for infill i do "combine layers = 5" ... but for some layer height and nozzle sizes it will go out of the "safety margin" that is extrusion width must be 20% more than layer height and if you for e.g. do 0.5mm line with 0.4mm nozzle and 0.25mm layer height if you set combine layers for infill to 2 it will try to print infill at 0.5mm layer height and that's not very safe with 0.4mm nozzle so you will get that warning

-

pay attention to "connect infill lines endpoints" makes a part stronger but adds basically one more perimeter so if you turn that on, you can drop one perimeter compared to s3d for e.g.

-

@arhi said in Slicer speed: S3d is faster then ideaMaker?:

"connect infill lines endpoints" makes a part stronger but adds basically one more perimeter so if you turn that on, you can drop one perimeter compared to s3d for e.g.

Very helpful!

I really appreciate all you have shared! -

@BlueDust glad it helps, just be sure to understand I'm not the IM master

I moved to it from S3D not long ago, I still know S3D much better, but I'm getting better results with IM so I'm not going back to S3D

I moved to it from S3D not long ago, I still know S3D much better, but I'm getting better results with IM so I'm not going back to S3D -

@arhi

I am in the same boat with S3d, and hope to move to iM. I just wish I stumbled upon it sooner. If I had known the main screen was setup like S3d, I would have started playing with it at least 6 months ago. Saying that, it does seem iM is a bit more complicated... a steeper learning curve then S3d. I have high hopes my transition to iM goes well. Once I stop doing test prints, and actually calibrate the extrusion multiplier for iM, I think I will feel much better about using it.

Also, I am am thinking about building another printer in the next month+ and if so, iM seems to be a bit easier to manage multiple printers then S3d would hae been. -

@BlueDust Chris Warkocki has a YouTube playlist on iM - https://www.youtube.com/watch?v=xpCn3DiZKgA&list=PLwRi4UU5eIHOQd7N5Mj8gasNTctZV5694

-

@BlueDust I try them all from time to time, still like the visual's and the organization of the craftware the best, also, the communication I had with different dev teams, craftware team was quickest to answer, most open and friendly than any other team I talked to, but while really eye candy and best gcode preview out there as a slicer they are not IMHO on par with IM.

I have this toolchanger sitting next to me for 9 months now and still not being turned on

( that now seems to be a mistake on my part, purchasing it from e3d but who knew the year would go to #%^$^#&* like 2020 did ) so I can't say how IM will behave with multiple tools. With dual nozzle it behaves "ok-ish", there are some things that I dislike (like left/right distinction, what's primary etc etc) but could work around .. I just hope it will work as expected with multiple tools when I need it to ..

( that now seems to be a mistake on my part, purchasing it from e3d but who knew the year would go to #%^$^#&* like 2020 did ) so I can't say how IM will behave with multiple tools. With dual nozzle it behaves "ok-ish", there are some things that I dislike (like left/right distinction, what's primary etc etc) but could work around .. I just hope it will work as expected with multiple tools when I need it to .. -

Thanks for the help guys!

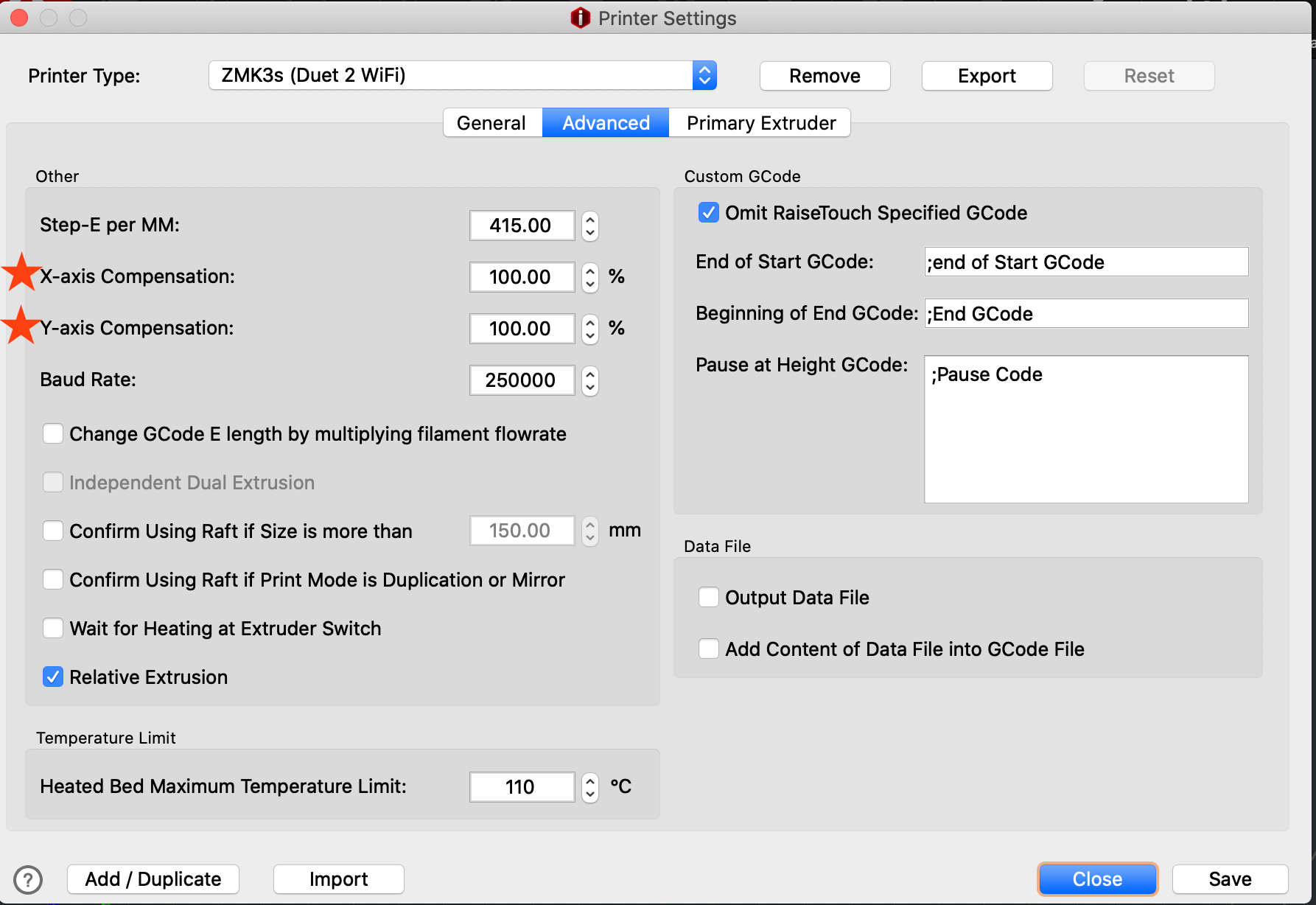

Where are the settings to adjust X or Y dimensional accuracy?

I printed a calibration cube, and X is a tad larger than expected, while Y is also a tad smaller... -

Is the dimensional accuracy evident regardless of which slicer you are using?

If it is evident, regardless of slicer being employed, I'd think that would mean that you should check your steps per mm in config.g with settings of M92?

If it is evident, regardless of slicer being employed, I'd think that would mean that you should check your steps per mm in config.g with settings of M92? -

@Kolbi

No... It worked fine in S3d. I checked two cubes I printed in S3d to confirm before I asked.

I just measured everything again and S3d was off by .03 or .04 mm difference of X and Y cube. iM seems more like .07mm+, but one of the walls is also thicker than the other 3, so that may be the problem. But it's only thicker by .05 mm (between thinnest and thickest wall)... I didn't have this much of a difference using S3d. The difference between .01 or .02 mm between walls was expected/normal. I will keep playing with this later, and not sure if I am being too picky or not. Will try and check belts ect. As I did complete a long print between these sets of cubes testing iM, something maybe lose.

I know where the setting is S3d is to adjust dimensional Accuracy and confirmed it was set to 0, so I never had to touch it. -

@BlueDust Ah, ok. Try going into printer settings and then the advanced tab.

-

@BlueDust said in Slicer speed: S3d is faster then ideaMaker?:

iM seems more like .07mm+

need to calibrate flow rate for the IM, you cannot use the same value as with S3D as I think they do the calculation differently

-

@arhi

I think I read some you or someone else already mentioning that???? I was printing 2 wall calibration cubes and found after a small change to the extrusion multiplier, I had 3 walls at .95 (should be .96) but the 4th wall was 1.00 and I didn't want to adjust it further until I fixed that. At the same time, I noticed the cubes Y was over 20mm and X was below 20mm, and asked for where settings were to fix that.... I really like the fact that iM will allow me to adjust both X and Y separately, as S3d only allows you to change Y if needed.

After I was able to get the cube to be perfect 20x20 mm, I noticed that a single corner was bulging out and obviously effected my measurements. I have to do this again, but as it was late I just printed a Mini to see how well it came out. This morning I found it was super stringy, and now want to run a temp tower in iM as the retractions I am using is way too high and putting holes in the print... Has to be a temp thing... Hopefully by the end of the day I will have enough prints done to get this situated. Just have to figure out how to make the proper temp tower/temp changes by layers in iM. I think I know where the setting are, just haven't try to mess with it yet. -

@Kolbi

Thank you! -

Is there a way to see the temp changes per layer like I can with speed, when looking at the preview? In S3d, I could do this by just setting it to color code each process, and temp change was per process... I don't see an option like that in iM and hoping I just don't know where it is.

-

@Blue, not that I know of.

-

I tried ideamaker but i could not find a way to connect it to duet, the doc's show a wlan setup but i could not find it, looked at all the settings it did not show a custom printer and if i was to enter a IP address it was also looking for a serial number, or wouldn't work.

Is there a way to connect to a custom printer?.Thanks