External bearings for stepper shafts

-

No doubt that a fully supported shaft is better for dealing with the belt tension.

I am not a big fan of flex couplings.

Given that trade, and given years of reliable operation on "cantilevered" steppers, I'd compromise by putting a support bearing on the tip of the stepper shaft, with a way to allow that bearing to "self align" and then clamp to immobility before the belt is tensioned.

But... that's all free opinion, and worth every penny.

-

It looks like you have space enough for a properly tensionable axle which could be belt driven by the stepper off to the side.

-

You could flip the pulley and have the belt closer to the stepper. This may take off some load off the back bearing.

-

@Danal said in Flexible coupling or direct mount for delta?:

No doubt that a fully supported shaft is better for dealing with the belt tension.

I am not a big fan of flex couplings.

Given that trade, and given years of reliable operation on "cantilevered" steppers, I'd compromise by putting a support bearing on the tip of the stepper shaft, with a way to allow that bearing to "self align" and then clamp to immobility before the belt is tensioned.

But... that's all free opinion, and worth every penny.

Anything specific that makes you not like the flex couplings? I have no clue, as I never worked with them before.

@Phaedrux said in Flexible coupling or direct mount for delta?:

It looks like you have space enough for a properly tensionable axle which could be belt driven by the stepper off to the side.

Do I understand correct that you mean two pulleys on the main axle, one for the actual tower belt and one for a 2nd belt that is driven by the stepper?

@zapta said in Flexible coupling or direct mount for delta?:

You could flip the pulley and have the belt closer to the stepper. This may take off some load off the back bearing.

I remember there being a reason why I didn't do this when I was designing my printer, but I must admit I cannot for the life of my remember or figure out why. I might still do this if nothing else.

-

@Nxt-1 said in Flexible coupling or direct mount for delta?:

Do I understand correct that you mean two pulleys on the main axle, one for the actual tower belt and one for a 2nd belt that is driven by the stepper?

Yup.

-

@Phaedrux said in Flexible coupling or direct mount for delta?:

Yup

Is the underlying assumption is that the second (short) belt will have a lower tension than the main belt? Otherwise it will be the same load on the stepper's bearing.

-

@zapta Yes. If the main belt is decoupled from the motor with it's own tensioner the motor won't need to bear as much tension. The short closed loop belt only needs to pull hard enough to keep the teeth engaged.

-

@Phaedrux said in Flexible coupling or direct mount for delta?:

@zapta Yes. If the main belt is decoupled from the motor with it's own tensioner the motor won't need to bear as much tension. The short closed loop belt only needs to pull hard enough to keep the teeth engaged.

Any argument as to why going this way instead of a flexible coupling, just curious? Just thinking about it quickly, it seems to me that introducing a 2nd small belt loop seems rather cumbersome. It would take most of the stress of the stepper bearings since the tension on the 2nd belt would not need to be as high. On the other hand you loose some space and you'd need some way of tensioning the 2nd belt. Since it would be so short, alignment/tracking is more difficult I believe.

-

@Nxt-1 Yes it would be a sizeable mechanical upgrade, but it would remove the tension, and you could even use different size pulleys to increase resolution.

From your photo it looked like you had quite a bit of space to work with. Alignment could be obtained in the same way the motor is currently mounted with a slot that gives you some wiggle room.

-

I have been bamboozled.

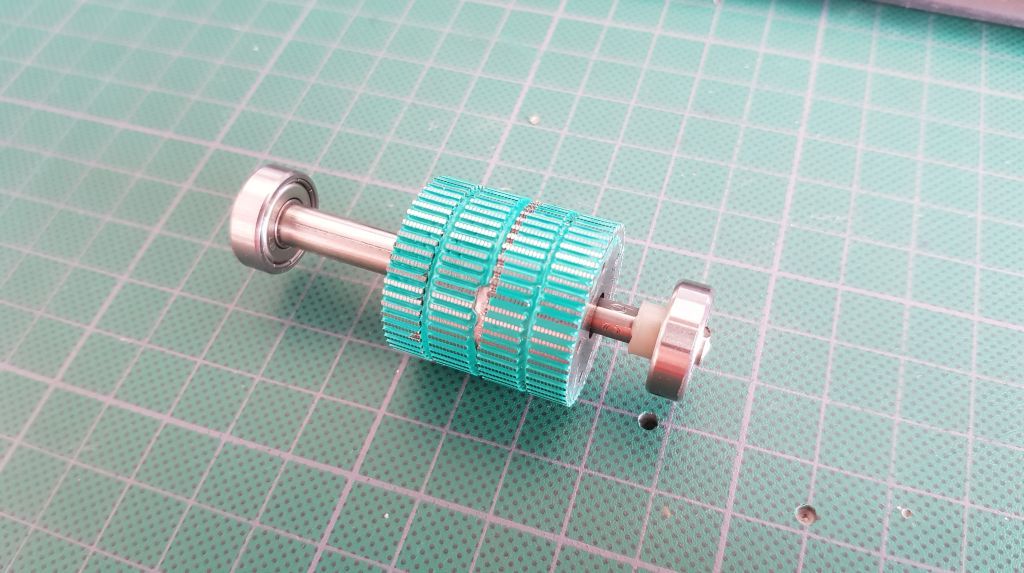

The last weeks I have been giving this idea some more thought. One of the solutions that came to mind was replacing the existing stepper shaft altogether for a longer version. I ordered some 5 mm diameter shafts and yesterday I opened one of the old nema 17 steppers to tryout this idea. Low and behold, the OD of the existing shaft is not 5 mm in all places. Where permanent magnet core sits over the shaft the OD is actually ~6,5 mm.

From what I have seen from other people taking apart steppers, this is not always the case. You never know before you open the steppers up though

-

there is another possible option and that is to use a dual shaft stepper and put a bearing on the rear shaft to take care of that side load.

-

@Nxt-1 you are aware that for some reason when you return the shaft back in to the casing your stepper will have 30-60% less torque compared to what it had before the operation? No clue why it happens, read it in some tech magazine ages ago, confirmed in practice few times

-

@Dougal1957 said in Flexible coupling or direct mount for delta?:

there is another possible option and that is to use a dual shaft stepper and put a bearing on the rear shaft to take care of that side load.

That is an interesting possibility indeed. The one issue that immediately comes to mind is availability. The choice is dual shaft steppers is quite a bit more restrictive.

-

@arhi said in Flexible coupling or direct mount for delta?:

@Nxt-1 you are aware that for some reason when you return the shaft back in to the casing your stepper will have 30-60% less torque compared to what it had before the operation? No clue why it happens, read it in some tech magazine ages ago, confirmed in practice few times

I did not know that. During I experiments with the shaft in the picture above, I did notice the core consists of four individual pieces that should really be placed on the new shaft in the exact same orientation, which probably is near to impossible. Apart from that, I can think of some more reasons as to why one would see a loss of torque but nothing that I can really support with experience nor evidence.

The gist of it is that I will not be going the shaft replacement route

-

@Nxt-1 Didn't say it would be easy but is a possibility OMC do do them but whether you can get them in the specs you want is something else LDO and MOONS are worth checking out as well. Pity Moons are so expensive else all mine would get swapped out

Doug

-

@Dougal1957 Thanks for the names of the suppliers, I'll check out what they have. Don't get me wrong, I do like the simplicity of the idea.

-

@Nxt-1 said in Flexible coupling or direct mount for delta?:

Where permanent magnet core sits over the shaft the OD is actually ~6,5 mm

FYI, Tech2C (the Hypercube designer) had this video about replacing stepper shafts https://www.youtube.com/watch?v=NmmFoBsSfEQ . The stepper he uses has consistent shaft diameter.

-

@Nxt-1 said in Flexible coupling or direct mount for delta?:

I did not know that. During I experiments with the shaft in the picture above, I did notice the core consists of four individual pieces that should really be placed on the new shaft in the exact same orientation, which probably is near to impossible. Apart from that, I can think of some more reasons as to why one would see a loss of torque but nothing that I can really support with experience nor evidence.

No clue what's the reason. To me it makes no sense, but I had to replace bearing on some steppers and all of them exibited exactly the described issue, when motor was reassembled it worked flawlesly but with less torque (around 50% less in my three instances). I did not reassemble shaft, just replaced bearings in the case.

One theory I heard is that if you allow core to touch the stator some magnetic $%#(&)^ happens and that's why you lose torque. I tried removing and returning the rotor in without stator touching the rotor at any point and by hand it's impossible for me, probbly some rig can be created but I gave up on "fixing/modifying" steppers as new ones with every possible mod already exist now and is accessible

-

-

@Danal said in Flexible coupling or direct mount for delta?:

@arhi said in Flexible coupling or direct mount for delta?:

magnetic $%#(&)^

Technical term?

I do electronics stuff good but I know ziltch about chemistry/mechanics of magnets and how different stuff affects them (apart from you heat the material, apply strong flux, let it cool and it becomes permanent magnet, you heat magnet, it loses the strength) so that's as tech as I can write about magnets

..

..anyhow one of the comments on the video where the guy replaces the shaft:

For anyone who is concerned with the loss of torque by disassembling their motors, don't be. This does NOT apply to the hybrid stepper motors that we use in our 3D printers.

Here's a video that debunks this myth: https://www.youtube.com/watch?v=A4WZm45XJ84I did all my tests where I did lose torque on old nema 23 motors (20+ years old that's why they were in need of repair) that were not of "hybrid" type. They do look identical inside to what he shown on the video so whatever the hybrid vs old stepper difference is...