Mesh calibration not working or what am I doing wrong?

-

Do you want to say that mesh calibration cannot compensate for more than 0.2mm?

-

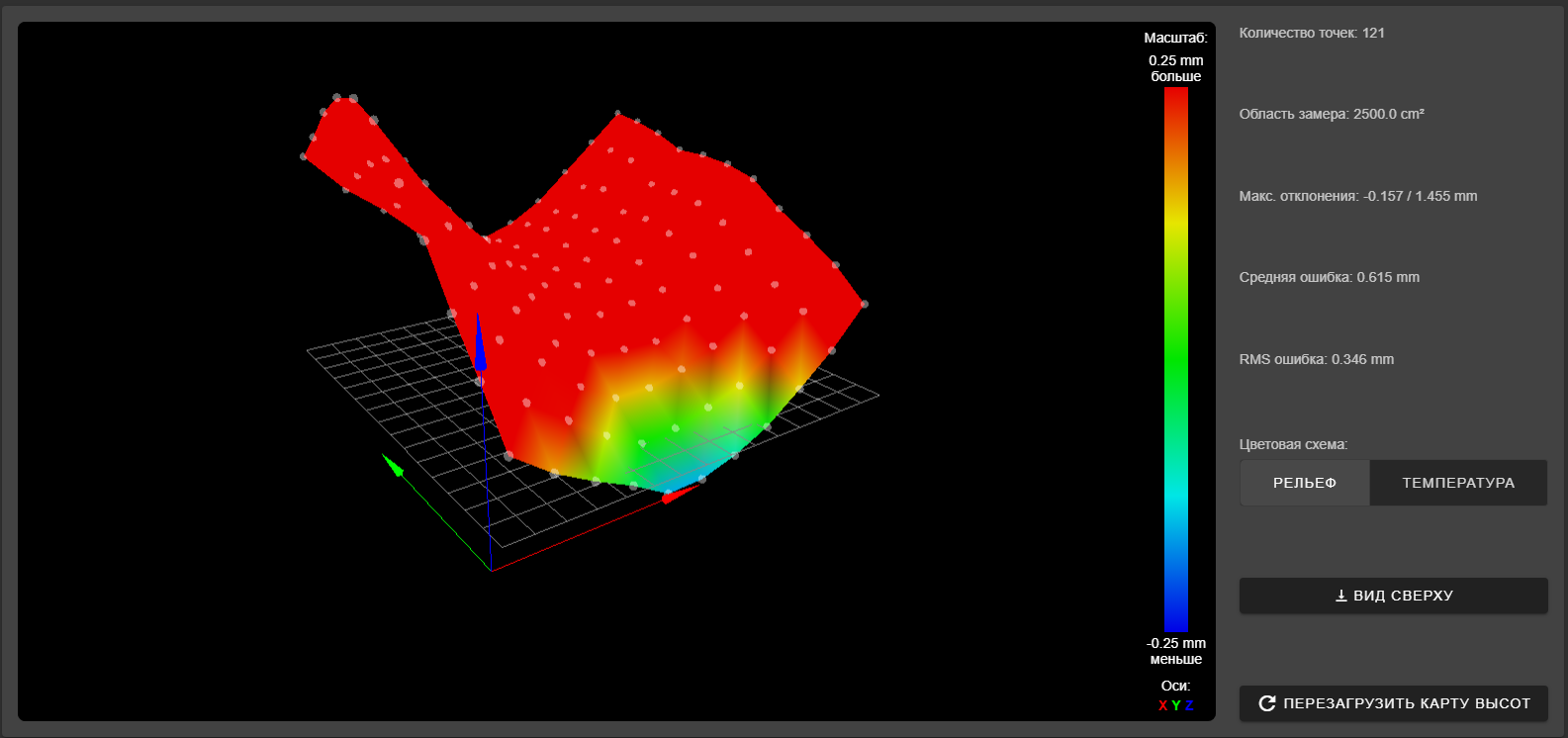

that looks absolutly terrible.

i am saying that if you have 0.2 between two points the area in between is calculated, so there could be deviations to the real values.

with a bed as uneven as that it is very likely that that is the case.however looking at our printer setup, it could also be a mechanical issue with your x gantry. because of the length it could be sagging and produces this result.

-

All axes are calibrated and checked. Dimensions of printed part + - 0.2 mm

OK. The table is very uneven. But for calibration, what does it matter?

Why doesn't calibration work in this range?

Is there a limitation?

-

@Dep said in Mesh calibration not working or what am I doing wrong?:

All axes are calibrated and checked. Dimensions of printed part + - 0.2 mm

axis sagging has nothing to do with dimension.

your x axis and y axis are over a meter long. they could bend under their own weight of the beam is not rigid enough.

that would lead to an image you are seeing, where the sides are higher and the middle is low. i.e the weight in the middle is causing more deflection that on the sides. -

Yes, I understand that.

But mesh calibration measures this deflection. Why is it not compensated during printing?

-

@Dep said in Mesh calibration not working or what am I doing wrong?:

M557 X500:1000 Y150:600 S25

thy with M557 X500:1000 Y150:600 S10

-

@Veti said in Mesh calibration not working or what am I doing wrong?:

thy with M557 X500:1000 Y150:600 S10

This is unfortunately impossible

The maximum number of points is 121

The maximum number of points is 121 -

But part of the model in the photo falls into several calibration points. Why are they not aligned?

-

@Dep said in Mesh calibration not working or what am I doing wrong?:

The maximum number of points is 121

https://duet3d.dozuki.com/Wiki/Using_mesh_bed_compensation

There is a firmware-dependent limit on the number of 441 probe points allowed.

-

I have a 0.8.5 board. And when i try to make more than 121 points, it gives an error.

But even with this number of points. They overlap the model. Why is it not calibrated.

I think there is some kind of limit on the calibration height.

I have spent many days and can not solve this problem.

There is no technical possibility to make a flat table on such sizes.I don’t know what to do next.

-

what firmware version are you using?

-

Duet 0.85

RepRapFirmware for Duet 1.25RC4 (2019-10-19b1) -

@Veti said in Mesh calibration not working or what am I doing wrong?:

M557 X500:1000 Y150:600 S10

03.11.2019, 14:40:36 M557 X500:1000 Y150:600 S10

Error: M557: bad grid definition: Too many grid points; suggest increase spacing to 47.4mm -

try decreasing the mesh area and see if the result improves, allowing more probing points in a smaller area.

-

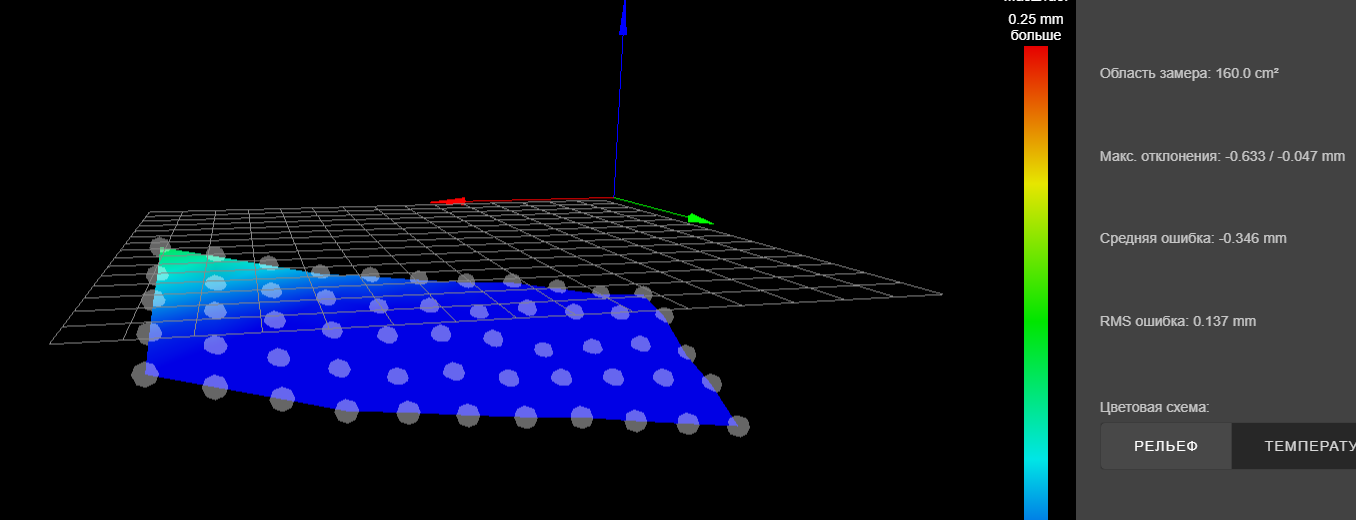

I tried to reduce to 20mm. That helped. But now I don’t know, maybe I came across a flat section of the table?

But I need the printer to work on a large table. I don’t understand what the problem is.

Why calibration is not working? There may be some kind of configuration problem.

After all, in theory, for firmware it does not matter how uneven the bed is.

Either there are limitations in the firmware, or maybe the adjustment is not accurate and it is not visible at small values. But it becomes noticeable with a large roughness.

-

@Dep said in Mesh calibration not working or what am I doing wrong?:

I tried to reduce to 20mm. That helped. But now I don’t know, maybe I came across a flat section of the table?

look at the mesh calibration image to check.

-

If you mean to look at the program code, then unfortunately I am not good at programming.

-

no the image of the you see after running mesh bed compensation.

-

Hi,

Have you ever defined a probing grid that covers the entire bed?

If not would you do that, probe the bed and post the height map here?

Thanks.

Frederick

-

Made a calibration with the parameters: M557 X500:700 Y150:230 S20

RepRapFirmware height map file v2 generated at 2019-11-03 18:06, min error -0.633, max error -0.047, mean -0.346, deviation 0.137 xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 500.00,700.00,150.00,230.00,-1.00,20.00,20.00,11,5 -0.329, -0.318, -0.282, -0.248, -0.238, -0.218, -0.195, -0.176, -0.133, -0.089, -0.047 -0.377, -0.358, -0.342, -0.314, -0.324, -0.287, -0.280, -0.235, -0.199, -0.162, -0.118 -0.484, -0.434, -0.434, -0.435, -0.375, -0.344, -0.337, -0.308, -0.259, -0.216, -0.163 -0.541, -0.507, -0.491, -0.479, -0.467, -0.427, -0.433, -0.389, -0.338, -0.282, -0.226 -0.633, -0.607, -0.580, -0.550, -0.533, -0.510, -0.484, -0.463, -0.407, -0.353, -0.298

I still can’t understand what this can give us?